PREVENTATIVE MAINTENANCE

AFTER EACH USE: CLEAN, LUBRICATE, ETC...

1.Thoroughly clean all equipment and accessories after each use.

a. Rinse solution tank, recovery tank, and hoses with clean water.

b. Flush entire solution system with clean water. This includes all solution hoses and attachment tool. Do not

allow liquid with cleaning chemicals to remain in the equipment.

c. Clean all filters (see below images: solution tank filter, solution line filter, vacuum filter. Optional: dump

pump and dump pump filter)

2. Lubricate all quick connects as needed.

3. Do not use the same container to fill the solution tank that is used to empty the waste tank. This would result in

putting dirt and debris into the solution lines that will block filters, orifices, and generally degrade the systems.

4. Keep equipment out of extreme temperatures. (i.e. Freezing temperatures will make water expand, and will

damage pump, fittings, valves, etc.)

5. Turn off the extractor whenever not in use. Do not walk away from an extractor, while unattended the extractor can

cause excessive pressure that is not good for it.

6. Check for loose or frayed wires.

10

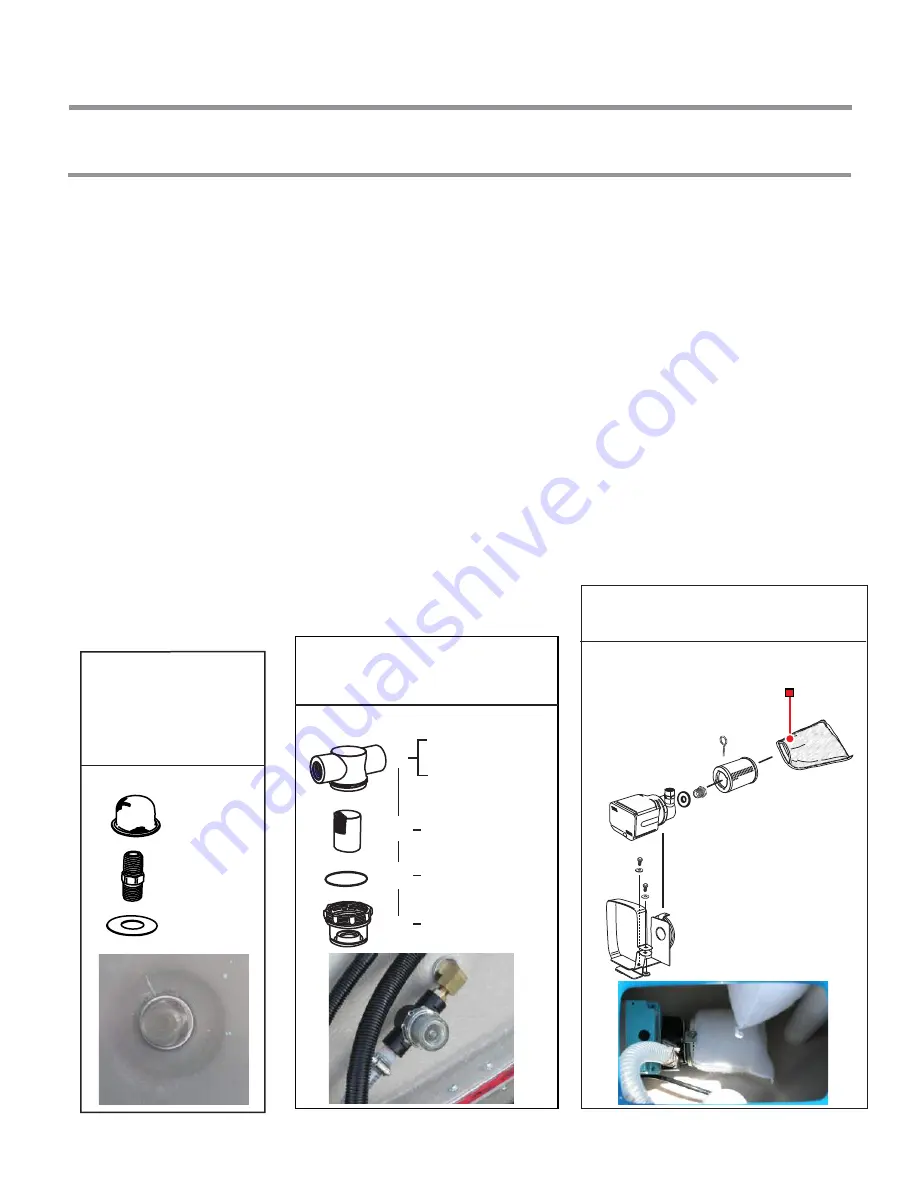

Solution line filter

(500 psi or higher)

Solution tank filter

located in solution

tank (all standard

models)

auto dump pump

auto dump pump filter

Auto Dump pump and

filter (optional)

ball bloat cage

IMAGES AND ILLUSTRATIONS ARE FOR REFERENCE ONLY. ACTUAL PRODUCTS MAY NOT BE EXACTLY AS SHOWN.

image 12.1

A

B

C

image 12.2

image 12.3

TF101050

1/4” = TF105010

(complete set)

TF105016

TF105015

TF105020

D

3/8” = TF105310

(complete set)

(PM 10150)

Summary of Contents for CF-100 Series

Page 2: ......