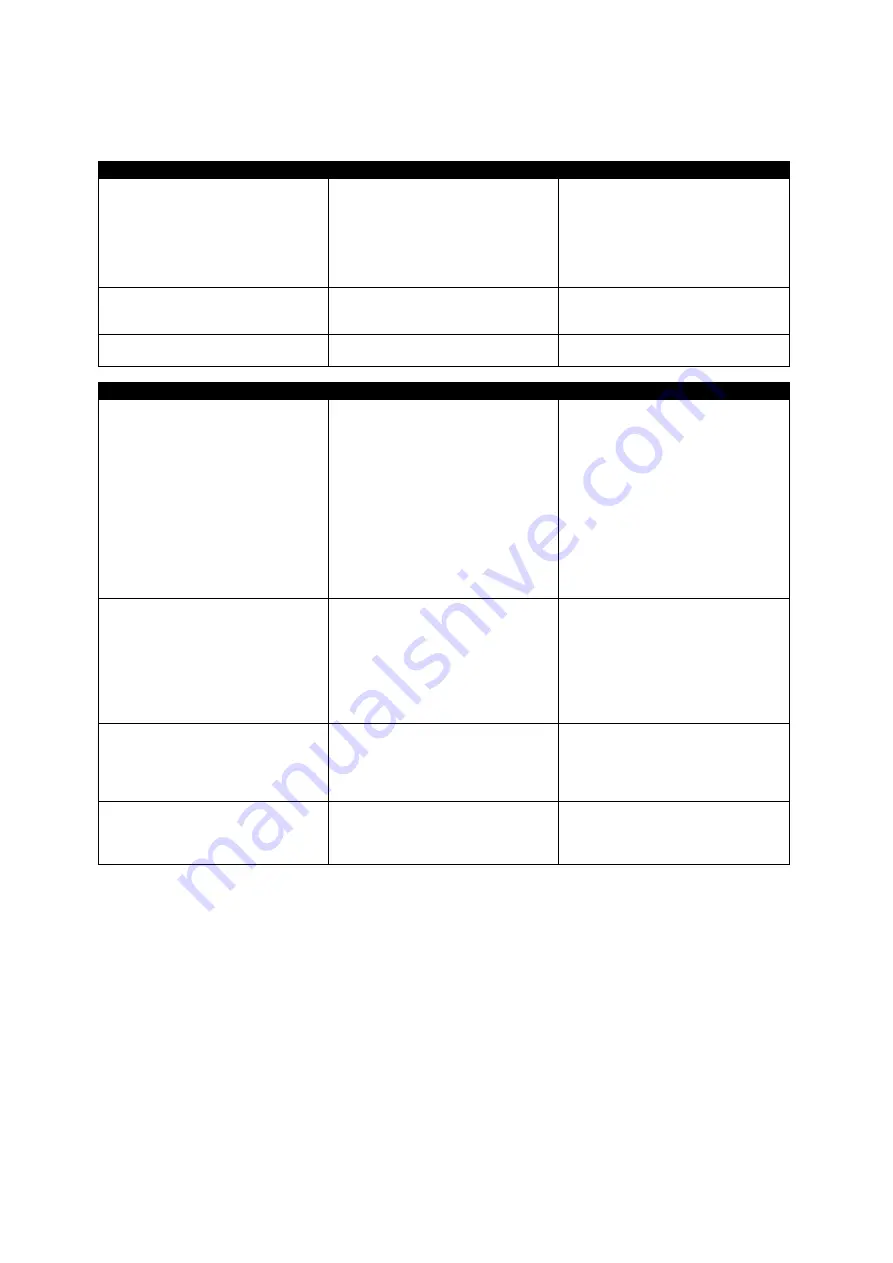

Possible problem and solution:

Symptom

Possible cause(s)

Corrective Action(s)

No detergent suction

units with tanks

1. Lance nozzle is not in low

pressure

2. High pressure extension

hose or high pressure

hose shorter than 25 feet.

3. Injector clogged on pump

1. Slide lance nozzle into low

pressure position

2. Remove high pressure

exten sion hose or use

high pressure hose is too

long

3. Call the dealer

No detergent Suction

Units with attachable applicators

Detergent applicator is clogged

1. Clean applicator with

warm water

2. Replace applicator

Unit begins to smoke

Overheated, overloaded or

damaged motor

Turn off unit and call the dealer

Descrizion

Causa possibile

Azione correttiva

Pressure washer does not start up

1. Unit is pressurized

2. Plug is not well

connected or electric

socket is faulty

3. Extension cord is too

long or wire size too

small

4. Main voltage supply is

too low.

5. Thermal safety switch

has tripped

1. Squeeze trigger on

gun

2. Check plug, socket

and fuse

3. Remove extension

cord

4. Check that main

supply voltage age is

adequate

5. Switch off unit and

allow motor to cool

down

Pump does not reach necessary

pressure

1. Water inlet filter is clogged

2. Pump is sucking air from

hose connections

3. Nozzle is worn or not

correct size

4. Unloader is clogged or

Worn

5. Valves is clogged or worn

1. Clean water inlet filter

2. Check that connections

and locking ring are

properly tightened

3. Call the dealer

4. Call the dealer

5. Call the dealer

Fluctuating Pressure

1. Pump is sucking in air

2. Clogged nozzle

3. Valves dirty, worn of stuck

4. Water seals worn

1. Check that hoses and

connections are tight

2. Clean with tip cleaner

3. Call the dealer

4. Call the dealer

Motor stops suddenly

1. Extension cord is too long

or wire size too small

2. Thermal safety switch has

tripped due to overheating

1. Remove extension cord

2. Check that main supply

voltage age corresponds

to specifications

INSPECTION & MAINTENANCE

For safety use, make sure a three-month clean the machine. Before working, make sure inspect the filter and the

nozzle, make sure there is no impurity. After working, make sure there is no water in the pump and the hose.

If the machine need to be repaired in the guarantee period, please return the machine to the shop. You need to

provide the certificate of purchase in order to repair or get the substitute.

Before Packaging, The machine should be cleaned, then use closed packaging, packaging should be firm.

Storage the machine in dry.

For transportation safety. The machine should comply with ISTA.

_ Damaged switches must be replaced by our after-sales service department.

_ If replacing the power cord is necessary, it should be done by the manufacturer or his agent to avoid a

hazard.

UFFICIO ASSISTENZA

_ Gli interruttori guasti devono essere sostituiti dal nostro Servizio Assistenza.

_ Per la sostituzione del cavo di alimentazione, è necessario l’intervento del costruttore o di un suo

Summary of Contents for 5411074176396

Page 33: ......