8

HKM 700 | 1.01

Operation

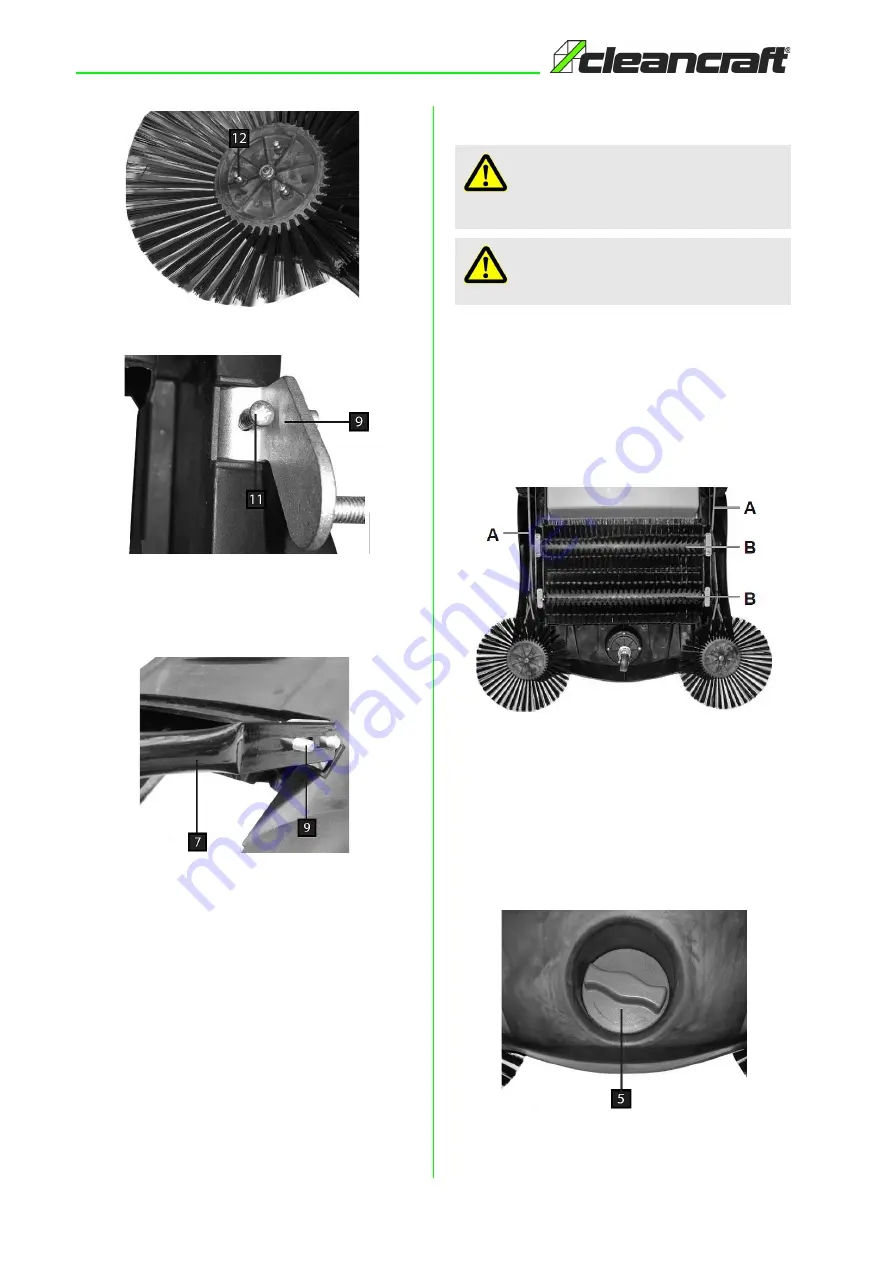

Fig. 4: Adjustment of the feed-in brush

Fig. 5: Adjustment of the push bar

Step 4: Put the bottom section of the push bar (Pos. 7,

Fig. 6) onto the push bar mounts (Pos. 9, Fig. 6)

and secure with he two adjustment nuts.

Fig. 6: Adjustment of the bar

Step 5: Slide the top section of the push bar onto the

bottom section of the push bar (Pos. 7, Fig. 6)

and secure with two adjustment nuts, two as-

sembly screws and the washers.

9

Operation

When the mechanical sweeper is pushed, the feed-in

brushes and the pick-up brushes (Pos. B, Fig. 7) are set

in rotation by the belt drives (Pos. A, Fig. 7).

The rotating feed-in brushes (Pos. 4, Fig. 3) sweep the

dirt to the centre. The two counter-rotating pick-up brus-

hes (Pos. B, Fig. 7) convey the dirt into the dirt container

(Pos. 4, Fig. 3)

Fig. 7: Functional principle

9.1 Adjusting the Feed-in Brushes

Use the setting screw (Pos.5, Fig. 8) to steplessly adjust

the height of the feed-in brushes as required. Turn the

setting screw clockwise to increase the distance to the

ground. Turn the setting screw counter clockwise to de-

crease the distance to the ground.

Fig. 8: Adjusting the feed-in brushes

WARNING!

For the ensure safe operation must regularly clean

the dirt container.

ATTENTION!

Do not use the device in wet conditions!