Clarke

®

American Sanders

Super E Operator's Manual

Page 9

ADJUSTMENT PROCEDURES (cont)

Condition - Pad creates a ridge on only one side of the

pad: Either rotate the stem of the side effected clock-

wise or rotate the stem opposite conterclockwise,

depending on whether the ridge terminates beyond the

tip of the pad or prior to it. If it is prior to the tip, adjust

the side effected, otherwise adjust the opposite side.

Belt Tension

The design of the belt allows it to deliver the power with

very little tenstion. The tension should be great

enough to prevent slippage and wear. Excessive

tension will only shorten bearing and belt life.

ROUTINE MAINTENANCE

Carbon Brushes

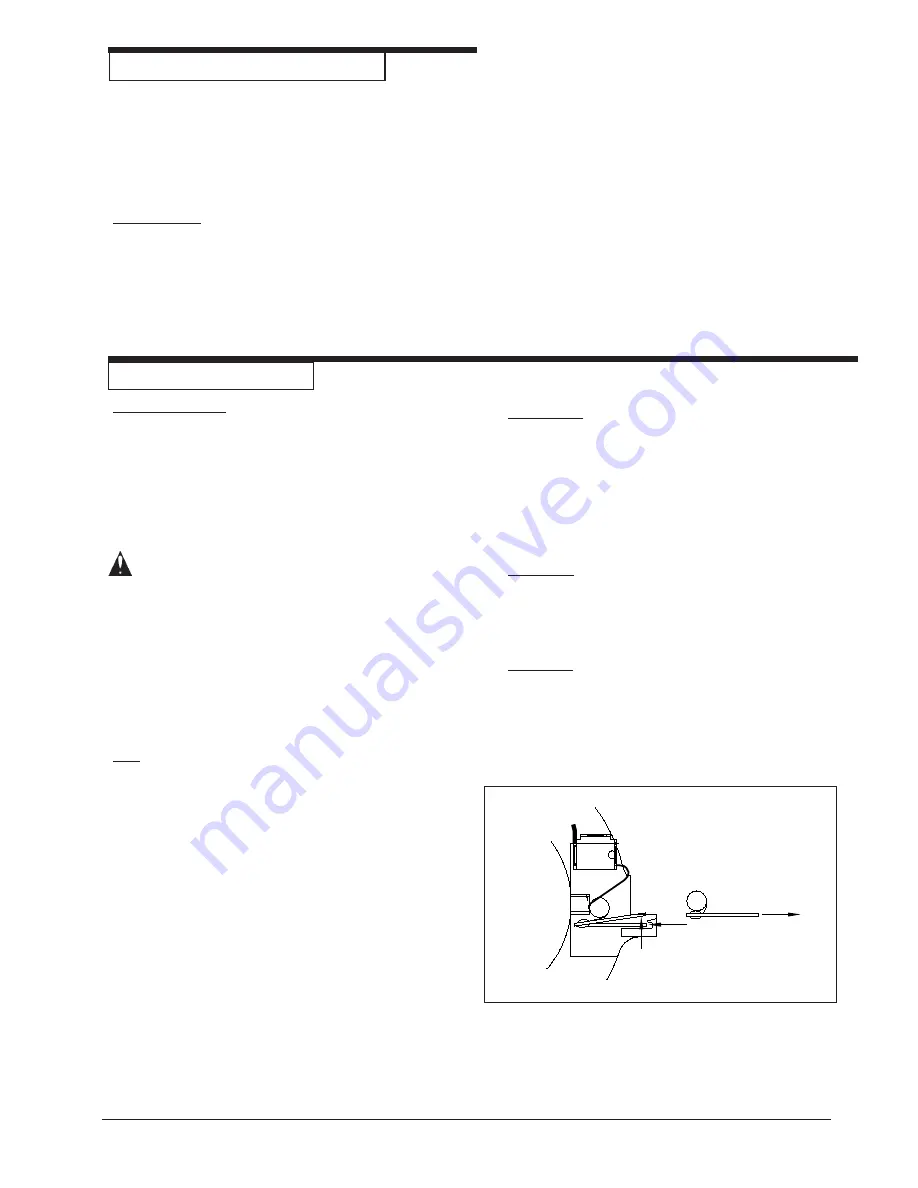

Inspect all four brushes every 6 months or 250 hours.

Access to the brushes is gained through the front and

back motor vent plugs and under both covers. Press

tab on spring clip assembly in, rotate, then remove

(figure 5). Use needlenose pliers to disconnect the

shunt wire. If any brush has worn to 3/8" in length or

shorter, replace the entire set.

CAUTION: Use only motor brush part no. 40818A

or 40055A with shunt wire or motor

failure will occur.

When replacing the brushes, make sure that the brush

seats against the commutator, the tab on the spring

clip assembly is fully seated in pocket, and the brush

is free to travel. When returning the switch covers,

keep all wires clear of the commutator and any pinch

sites.

Pad

In time the elastomer on the pad may wear or become

damaged. To replace, remove pad by placing screw-

driver in slot of shaft, grasp pad and rotate shaft

counterclockwise. Remove existing elastomer and

clean hub throughly to remove old adhesive. Roughen

surface of new elastomer to provide good bond sights.

Apply a good rubber cement to both surfaces and allow

to tack. 3M# 1300 rubber and gasket cement is a

suitable choice. Apply elastomer to hub and knead

throughly. Apply pressure to elastomer and allow to

stand over night. Apply a medium strength thread

locker to the external threaded end of the shaft. Install

belt in grooves on hub and screw down on shaft.

Install abrasive retainer on to shaft. Locate a flat

surface and tape 80 grit abrasive to surface. Using

machine "dress in" by sanding the elastomer on the

pad. Continue sanding until the entire surface of the

elastomer shows signs of sanding. As in operation of

the machine, take precautions performing this proce-

dure.

Pad Driver

Periodically inspect belt grooves on pad driver for an

accumulation of paint or varnish especially after jobs

where several layers of paint or varnish have been

removed. Particles of paint or varnish can deposit in

the grooves, creating vibration and damaging the

drive belt. Use a plastic putty knife or similar object to

remove the deposits.

Dust Bag

Periodically the dust bag should be turned inside out,

shaken vigorously and machine washed in cold water

to prevent pore blockage and loss of dust control.

Bearings

To insure reliable performance, armature and pad

driver bearings should be inspected for wear or

damage after 1500 hours. If used heavily the bear-

ings should be replaced seasonally.

Figure 5