5

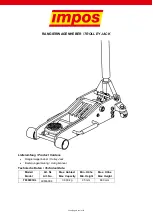

4. Fit the operating lever into the jacking port and pump the operating lever

to raise the saddle until it reaches the jacking point.

5. Make sure that the saddle is in full contact with the lifting point and that

there is nothing that will prevent a clean lift. Keep all personnel at a safe

distance before lifting.

6. Pump the operating lever to raise the vehicle to the required level.

NOTE:

If, at any time, the jack feels spongy, follow the bleeding

procedure under Maintenance.

7. Position suitable, good quality axle stands directly beneath the supporting

points on the vehicle. Place the operating lever over the release valve and

very gently twist anti-clockwise to lower the load onto the stands.

8. Check constantly, preferably with an assistant, that the vehicle is resting

correctly on the axle stands and that the stands are stable before the

weight is taken.

9. Ensure that the axle stands cannot move when supporting the load.

10. To stop it lowering at any point, turn the operating lever clockwise again.

Always avoid a rapid descent by turning the operating lever slowly.

NOTE:

Ensure this is carried out under complete control. DO NOT allow

the load to drop suddenly as this could damage internal parts.

11. Completely remove the jack from the vehicle.

MAINTENANCE

CHECKING THE OIL LEVEL

1. Ensure the jack is fully lowered by

turning the release valve fully anti-

clockwise.

2. Remove the cover plate and filler

plug.

• The oil should be almost level

with the bottom of the filler hole

• Oil can be topped up using

Clarke Hydraulic Oil (p/n

3050830 1 litre).

3. Replace the filler plug/cover plate and bleed any air from the system.

Summary of Contents for CTJ2000LPB

Page 7: ...7 DECLARATION OF CONFORMITY...

Page 8: ......