5

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

BEFORE USE

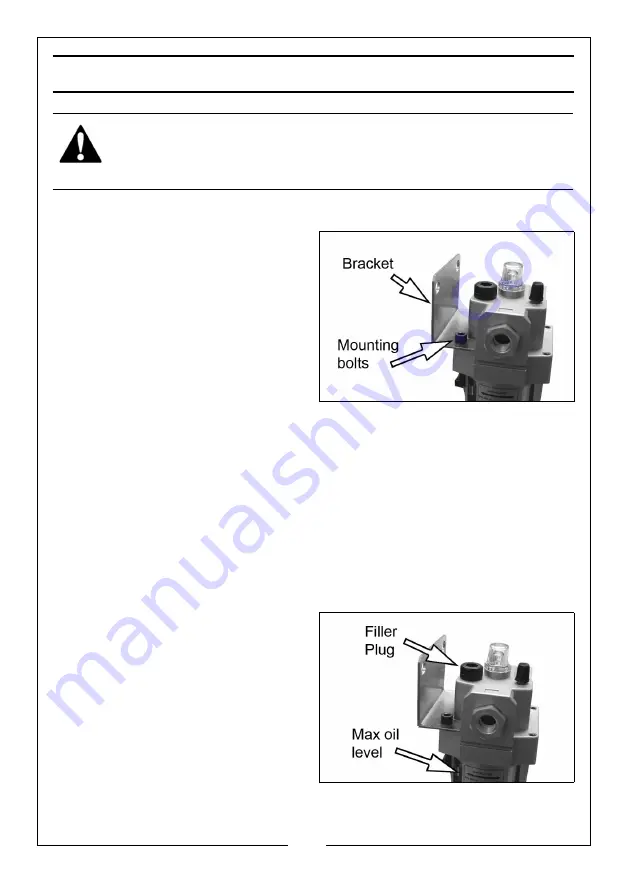

MOUNTING THE UNIT

This lubricator is supplied with a

bracket for mounting it to a wall or

any suitable framework. It should

ideally be connected to a fixed airline

or be mounted on the outlet of the

compressor.

• Airflow direction is marked with

an arrow on the lubricator body.

Ensure sufficient free space above the

lubricator for future adjustments.

Take care not to overtighten when connecting the airline unions.

Make sure that the compressed air is not contaminated with solvents to such

an extent as to cause damage to internal components.

Ensure the compressor is turned off when making connections.

After connection, turn on the air supply and check for air leaks. Rectify any

found before starting work.

• PTFE tape may be useful for sealing threaded connections.

FILLING THE OIL CONTAINER

1. Unscrew the filler plug using an 8

mm allen key and fill the lubricator

with oil up to the “Max Oil Level”

mark on the side of the bowl. Do

not overfill.

• This can be done without

shutting off air pressure to the

lubricator. Use good quality,

light, misting type of oil for air-

powered tool/motors.

• Suitable oil should be used such as Clarke Airline Oil (part no

3050825).

WARNING: COMPRESSED AIR CAN BE DANGEROUS. ENSURE THAT YOU

ARE FAMILIAR WITH ALL PRECAUTIONS RELATING TO THE USE OF AIR

COMPRESSORS AND COMPRESSED AIR SYSTEMS.

Summary of Contents for Air CAT162

Page 8: ......