8

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

USING YOUR BUFFER/POLISHER

1. Plug the buffer/polisher into the mains power supply.

2. Switch the buffer/polisher on

3. Slowly bring the workpiece into

contact with the polishing mop.

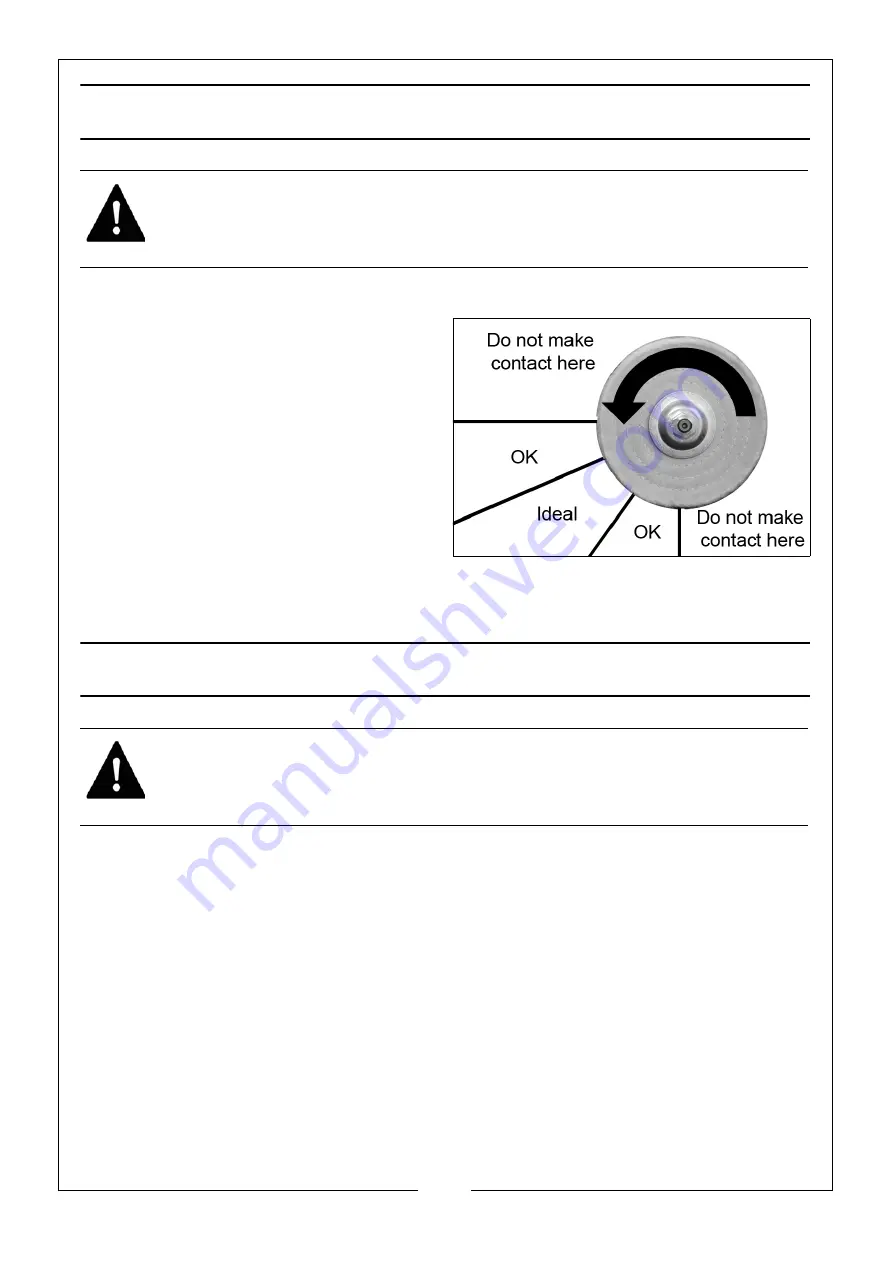

• See the image on the right to

determine the safest and best

position for contact with the

wheel.

• DO NOT contact the wheel

outside of the quadrant.

4. After use, unplug the buffer/polisher from the mains power supply, and

clean the machine ready for next use.

MAINTENANCE

1. Regularly inspect the buffing/polishing pad. Replace when worn.

2. Keep the buffer/polisher clean and dry. DO NOT use abrasives.

3. The motor and bearing are sealed units and require no maintenance.

CLEANING & STORAGE

1. Clean the exterior the machine if required using a mild detergent or mild

solvent.

2. Never immerse the buffer/polisher in water.

3. Keep any cooling vents in the buffer/polisher free of debris.

WARNING: BEFORE COMMENCING WORK, ENSURE YOU HAVE READ AND

UNDERSTOOD ALL OF THE SAFETY INSTRUCTIONS

WARNING: MAKE SURE THAT THE BUFFER/POLISHER IS UNPLUGGED FROM

THE MAINS POWER SUPPLY BEFORE PERFORMING ANY MAINTENANCE.

Summary of Contents for 6500485

Page 12: ......