CHAPTER 1

Disassembly,Reassembly,Maintenance

Contents

1. Cautions Concerning Maintenance ........................................................................ 1-1

2. Supplying Oil ........................................................................................................... 1-2

3. Maintenance Tools ................................................................................................... 1-3

4. Other ......................................................................................................................... 1-3

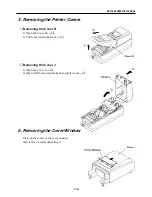

5. Removing the Printer Covers ................................................................................. 1-4

■

Removing the Cover R .......................................................................................... 1-4

■

Removing the Cover J ........................................................................................... 1-4

6. Removing the Cover Window ................................................................................. 1-4

7. Removing the Journal Cover Key .......................................................................... 1-5

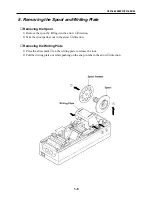

8. Removing the Spool and Writing Plate ................................................................. 1-6

■

Removing the Spool .............................................................................................. 1-6

■

Removing the Writing Plate ................................................................................... 1-6

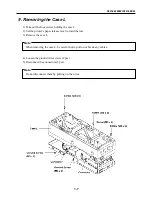

9. Removing the Case L ............................................................................................... 1-7

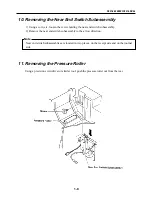

10. Removing the Near End Switch Subassembly ...................................................... 1-8

11. Removing the Pressure Roller ................................................................................ 1-8

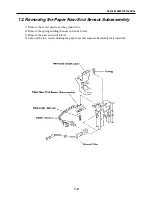

12. Removing the Paper Near End Sensor Subassembly ........................................... 1-9

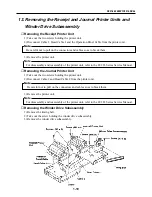

13. Removing the Receipt and Journal Printer Units and

Winder Drive Subassembly .................................................................................. 1-10

■

Removing the Receipt Printer Unit ...................................................................... 1-10

■

Removing the Journal Printer Unit ...................................................................... 1-10

■

Removing the Winder Drive Subassembly .......................................................... 1-10

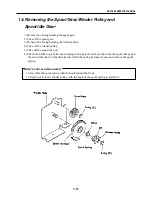

14. Removing the Spool Gear, Winder Pulley and Spool Idle Gear ........................ 1-11

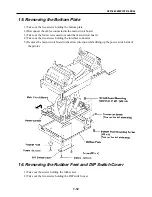

15. Removing the Bottom Plate .................................................................................. 1-12

16. Removing the Rubber Feet and DIP Switch Cover ............................................ 1-12

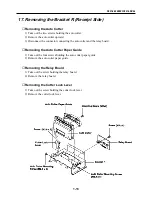

17. Removing the Bracket R (Receipt Side) .............................................................. 1-13

■

Removing the Auto Cutter ................................................................................... 1-13

■

Removing the Auto Cutter Paper Guide .............................................................. 1-13

■

Removing the Relay Board .................................................................................. 1-13

■

Removing the Cutter Lock Lever ........................................................................ 1-13

■

Removing the Printer Mechanism ....................................................................... 1-14

■

Removing the Operation Panel Board and the Cover Open Switch Board ......... 1-14

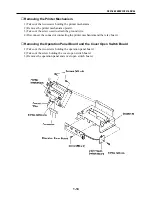

18. Removing the Bracket J (Journal Side) ............................................................... 1-15

■

Removing the Printer Mechanism ....................................................................... 1-15

■

Removing the Relay Board .................................................................................. 1-15

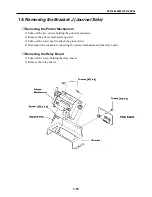

19. Cautions Concerning Reassembly and Adjustments .......................................... 1-16

■

Cautions When Reassembling the Case L ........................................................... 1-16

■

Cautions When Reassembling the Winder Drive Subassembly .......................... 1-17

■

Adjusting the Near End Switch Subassembly ...................................................... 1-18

■

Adjusting the Timing Belt .................................................................................... 1-19

Summary of Contents for CBM-262 Type II

Page 1: ...LINE THERMAL PRINTER MODEL CBM 262 Rev 1 00 First created June 18th 1996 Service Manual ...

Page 2: ...i REVISION Rev No Date Content Rev 1 00 June 18 1996 First created ...

Page 4: ...CHAPTER 1 DISASSEMBLY REASSEMBLY MAINTENANCE ...

Page 25: ...CHAPTER 2 CIRCUIT DIAGRAMS ...

Page 27: ...CBM 262 SERVICE MANUAL 2 1 1 INTER CONNECTION RC 232C ...

Page 28: ...CBM 262 SERVICE MANUAL 2 2 2 MAIN PCB RC 232C CPU ...

Page 29: ...CBM 262 SERVICE MANUAL 2 3 MAIN PCB RC 232C MEMORY ...

Page 30: ...CBM 262 SERVICE MANUAL 2 4 MAIN PCB RC 232C GATE ARRAY ...

Page 31: ...CBM 262 SERVICE MANUAL 2 5 MAIN PCB RC 232C PANEL CONT DRAWER ...

Page 32: ...CBM 262 SERVICE MANUAL 2 6 MAIN PCB RC 232C HEAD CONT DIP SWITCH ...

Page 33: ...CBM 262 SERVICE MANUAL 2 7 MAIN PCB RC 232C RECEIPT CONT ...

Page 34: ...CBM 262 SERVICE MANUAL 2 8 MAIN PCB RC 232C JOURNAL CONT ...

Page 35: ...CBM 262 SERVICE MANUAL 2 9 MAIN PCB RC 232C POWER ...

Page 36: ...CBM 262 SERVICE MANUAL 2 10 MAIN PCB RC 232C SERIAL I F ...

Page 37: ...CBM 262 SERVICE MANUAL 2 11 3 INTER CONNECTION CENTRONICS ...

Page 38: ...CBM 262 SERVICE MANUAL 2 12 4 MAIN PCB CENTRONICS CPU ...

Page 39: ...CBM 262 SERVICE MANUAL 2 13 MAIN PCB CENTRONICS MEMORY ...

Page 40: ...CBM 262 SERVICE MANUAL 2 14 MAIN PCB CENTRONICS GATE ARRAY ...

Page 41: ...CBM 262 SERVICE MANUAL 2 15 MAIN PCB CENTRONICS PANEL CONT DRAWER ...

Page 42: ...CBM 262 SERVICE MANUAL 2 16 MAIN PCB CENTRONICS HEAD CONT DIP SWITCH ...

Page 43: ...CBM 262 SERVICE MANUAL 2 17 MAIN PCB CENTRONICS RECEIT CONT ...

Page 44: ...CBM 262 SERVICE MANUAL 2 18 MAIN PCB CENTRONICS JOURNAL CONT ...

Page 45: ...CBM 262 SERVICE MANUAL 2 19 MAIN PCB CENTRONICS POWER ...

Page 46: ...CBM 262 SERVICE MANUAL 2 20 MAIN PCB CENTRONICS CENTRONICS I F ...

Page 47: ...CBM 262 SERVICE MANUAL 2 21 5 OPE PANE PCB ...

Page 48: ...CBM 262 SERVICE MANUAL 2 22 6 CONNECT PCB 1 ...

Page 49: ...CBM 262 SERVICE MANUAL 2 23 7 CONNECT PCB 2 ...

Page 50: ...CHAPTER 3 PARTS LISTS ...

Page 53: ...CBM 262 SERVICE MANUAL 3 2 Sample layout Main PCB RS 232C Parts side ...

Page 54: ...CBM 262 SERVICE MANUAL 3 3 Sample layout Main PCB RS 232C Soldered side ...

Page 59: ...CBM 262 SERVICE MANUAL 3 8 Sample layout Main PCB Centronics Parts side ...

Page 60: ...CBM 262 SERVICE MANUAL 3 9 Sample layout Main PCB Centronics Soldered side ...

Page 64: ...CBM 262 SERVICE MANUAL 3 13 Sample layout Ope Pane PCB Parts side Soldered side ...

Page 67: ...CBM 262 SERVICE MANUAL 3 16 Sample layout Connect PCB 1 Parts side Soldered side ...

Page 70: ...CBM 262 SERVICE MANUAL 3 19 Sample layout Connect PCB 2 Parts side Soldered side ...

Page 73: ...CBM 262 SERVICE MANUAL 3 22 Drawing No 1 General Assembly ...

Page 76: ...CBM 262 SERVICE MANUAL 3 25 Drawing No 2 Mechanism Unit ...

Page 79: ...CBM 262 SERVICE MANUAL 3 28 Drawing No 3 Electrical Component Unit RS 232C I F Centronics I F ...

Page 83: ...CHAPTER 4 APPENDIX ...

Page 84: ...CHAPTER 4 Appendix Contents External View 4 1 ...