6

VALVE SETTING

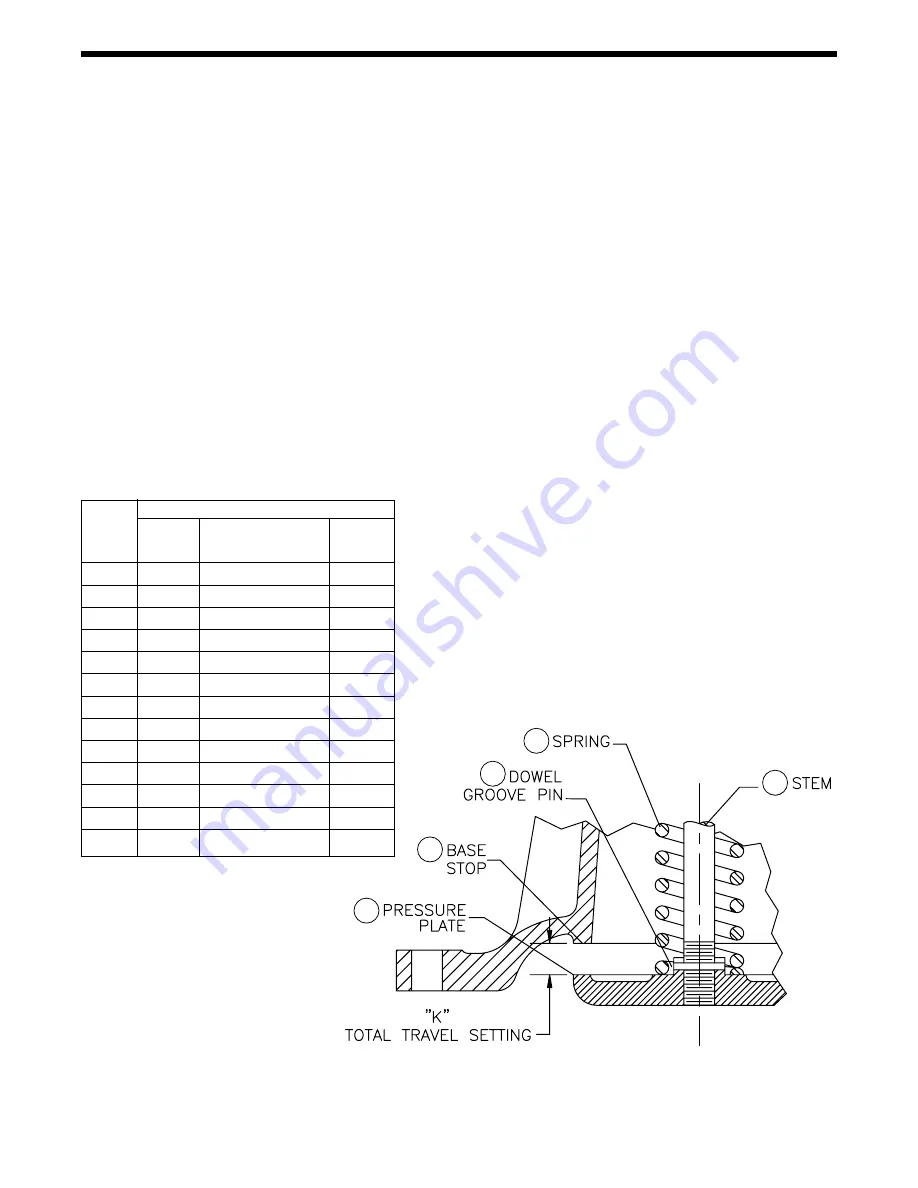

Valve setting is gaged at K to establish correct stem

length and diaphragm position. Dimension “K” is sup-

plied with each replacement stem. For metal dia-

phragm valves, “K” is cast on the upper face of pres-

sure plate (15) (Fig. 6).

To install new stem (12), fasten disc (7) (see Fig. 7)

firmly on stem with stem nut. Insert stem and disc

assembly in valve and screw on pressure plate (15).

Omit spring (13) for this operation. Hold disc on seat

and adjust position of pressure plate until valve setting

“K” is reached. Push pressure plate against stops in

base (11). Remove disc, drop out pressure plate and

stem, drill and insert dowel pin (14) to lock the joint.

Grind off stem projection flush with face of pressure

plate.

VALVE

TRAVEL SETTING

SIZE

TOTAL

GROOVE

DRILL

TRAVEL

PIN

SIZE

3/4

1/4

1/8 X 11/16

1/8

1

5/16

1/8 X 11/16

1/8

1

1

⁄

4

3/8

5/32 X 13/16

5/32

1

1

⁄

2

7/16

5/32 X 13/16

5/32

2

9/16

5/32 X 15/16

5/32

2

1

⁄

2

1

1

⁄

16

3/16 X 15/16

3/16

3

1

3

⁄

16

3/16 X 1

3

⁄

8

3/16

4

1

1

⁄

16

1/4 X 1

3

⁄

4

1/4

5

1

5

⁄

16

5/16 X 1

3

⁄

4

5/16

6

1

9

⁄

16

5/16 X 2

5/16

8

2

1

⁄

16

3/8 X 2

3/8

10

2

9

⁄

16

3/8 X 2

1

⁄

2

3/8

12

3

1

⁄

16

1/2 X 2

3

⁄

4

1/2

FIGURE 6

REPLACING SEAT RINGS

These joints should be made up with Copaltite,

Permatex or equal high temperature gasket com-

pound. Remove old compound from body and seat

ring with a wire brush. Apply new compound sparing-

ly to both parts, threads and shoulders. Let stand until

tacky before assembling.

GRINDING IN (Lapping)

Seats and discs should never require more than the

lightest touch up with very fine (400 grit) grinding com-

pound. Heavy grinding will produce galling, wider

seating surface and a groove in the disc, all of which

tend to cause leakage. Reface a damaged surface

before attempting to grind it in. Grind sparingly.

Main stem (12) shown on Figure 6 is slotted for rotation

with a screwdriver, Valve spring (13) is omitted from

the assembly during grinding. Slip the stem into its

normal position. apply compound to the disc, place it

on the stem and tighten with one stem nut.

After grinding, disassemble and clean all parts.

MAINTENANCE

15

11

12

13

14