M6 SERIES IOM

6th EDITION

ISSUED 12/2014

23

8. Rotate the pinion to the open position. Orient the pistons correctly according to your operation type and slide

them into the body until both racks engage with the pinion. (For correct orientation of pistons refer to p.34 of

this manual)

9. Check closed position. Likely, the actuator will stop before the closed position either because of uneven

engagement of the racks or because of improper orientation of the pinion. In either case, turn the actuator on end

and while applying light but firm pressure to the top piston rotate to pinion so that it slowly backs the pistons out

of the actuator until you feel the pinion skip a tooth. Apply even pressure to both pistons and recheck closing

position. Max over travel at close (closed stop disengaged) should be roughly 5 degrees. Repeat until the

actuator operates correctly. Before proceeding use the checklist below entitled “Piston Calibration Checklist” to

ensure correct operation of the actuator. If the answer to any question below is “no”, disengage the pinion from

the pistons and repeat from step 8.

Piston Calibration Checklist

To ensure pistons are aligned correctly check the following

-Closed position: Does the actuator close with the pinion correctly aligned?

-Travel:

Does the actuator travel a full 90°?

-Open position: At fully opened position is the pinion aligned correctly?

At fully opened position is the air inlet blocked? (See Below)

-Pistons:

Are both pistons equal distances inside the body?

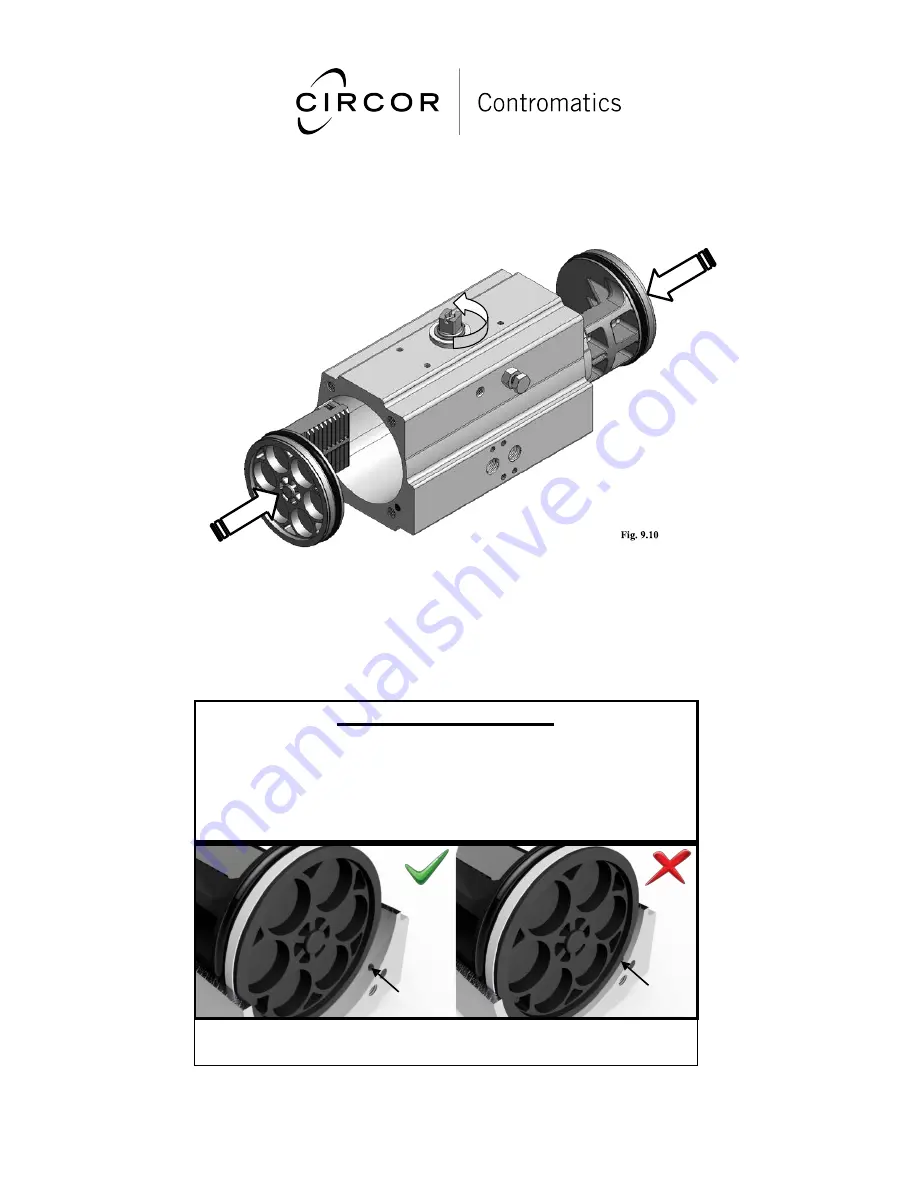

The arrow in both illustrations above points to the air inlet while the actuator is in the fully open position.

In the illustration on the left the air inlet is unobstructed and the actuator will function normally.

In the illustration on the right the inlet is obstructed and the pistons need to be realigned.