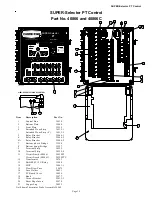

SUPER-Selector

‘

PT Control

Page 10

Calibrating the Sensors

Note: This procedure is not normally required.

In order to calibrate a sensor, it will be necessary to attach an accurate

calibration thermometer directly to that sensor for several minutes. Use the

same calibration thermometer for each sensor calibrated. From the factory the

sensors should be accurate within ± 1.5 degrees F. (± .8 degrees C.).

1. Set the master selector switch to the unlabeled position. The display window will

show (- - - -) do not attempt to edit the display while (- - - -) is displayed. Set the

HEAT A switch one position left of ON. The display window will now

show 1 for a 40866 control and 0 for a 40866C control.

2. Use the Edit Switch to change the display to any number from 128 to 255.

3. The display window will now show the temperature being read by the sensor

selected by the sensor selector.

4. Use the edit switch to change the reading to be the temperature shown by the cali-

bration thermometer. The selected sensor has just been calibrated.

5. Turn the sensor selector to the next sensor to be calibrated and move the calibra-

tion thermometer to the next sensor to be calibrated.

Perform steps 4 on this sensor.

6. Perform steps 4 & 5 on each of the remaining sensors to be calibrated.

7. To exit this function, turn the master selector switch to any setting outside the

unlabeled position and return the HEAT A switch back to its appropriate posi-

tion.

All the sensors can be calibrated at once prior to installation by placing them all in

a bucket of water along with an accurate calibration thermometer. The water must

be stirred as you perform the calibration. Failure to do this might actually degrade

the accuracy.