Chapter

1Product Usage Precautions

CMN023-005

原本

(original instructions)

37

E

nglis

h

Chapter 1

Product Usage Precautions

Safety Notations

This instruction manual describes usage precautions with the below listed symbols.

Be sure to read the instructions.

Symbol

Meaning

WARNING

Indicates a hazardous situation which, if not avoided, could result in personal death or

serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result personal injury or

damage to the device.

Indicates a prohibited action (which MUST NOT be done).

Indicates a mandatory action (which MUST be done).

Precautions for Transport, Storage, and Relocation

WARNING

•

Transportation must be done using at least two people.

Injury may result due to fall hazard.

CAUTION

•

Relocation and storage must be done in a safe location within the

temperature range of -10°C to 60°C at relative humidity of 80% or less.

Precautions for Installation

WARNING

•

Do not install the device in or around an area with flammable, explosive, or

corrosive mist, smoke, or gases.

CAUTION

•

This device is designed for installation in a cleanroom or a clean factory.

Avoid installation in other areas, such as outdoors.

•

Ensure a wide suction port.

If the device is used continuously with a narrow suction port (i.e., at high

pressure), the motor may become hot as it cannot be cooled.

•

Install the device in a horizontal, vibration-free location as it contains rotating

equipment.

•

Install the device at normal temperature (ambient temperature 0°C to 40°C, at

humidity 80% or less) without dew condensation.

High temperature or dew condensation may cause failure of electrical

components or electric shock.

•

Beware that suction ambient temperature (temperature around the dust to

be collected) is low enough, because otherwise the motor may lead to

performance reduction or failure.

•

Provide a sufficient space for the exhaust port (at least 100 mm from the

exhaust port).

If the exhaust port is blocked, the proper suction power cannot be delivered.

Furthermore, sufficient cooling is not provided in the box, causing burnout of

the motor or failure of electrical components.

•

The installation site should be at an altitude of 1,000 m or less.

Summary of Contents for CBA-1500AT3-HC-DSA-V1

Page 6: ...1 4 1 4 2 OFF 1 5...

Page 7: ...1 CMN023 005 Translation of the original instructions 5 1 6...

Page 8: ...2 6 2 2 1 200V 220 230V CE 1 1 2 1 1 HEPA 1 3m 200V 1 220 230V CE 1 1...

Page 12: ...2 10 2 4 3 OP kPa SP kPa DP kPa EP kPa Blower Runtime h 18 Total h Moter...

Page 13: ...3 CMN023 005 Translation of the original instructions 11 3 3 1 3 1 1 0 40 80 RH REMOVE 1 1 1...

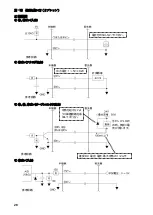

Page 14: ...3 12 1 2 2 3 4 OFF ON 1 A OFF 40 50 A 2...

Page 22: ...5 20 5 5 1 WARN2 1 5 1 1 1 1 1 2 2 1 3 1 4 2 1...

Page 24: ...5 22 3 ACC 4 5 6 5 2 1 Littell fuse 218 250V 15A 1 2 3 ACC...

Page 28: ...5 26 5 7 EL ON ON 5 2 22 1 2 3 4 1 4 ON OFF 30 1 2 1 2 5 1 20 5 1 20 5 1 20 5 1 20...

Page 29: ...6 CMN023 005 Translation of the original instructions 27 6 6 1 6 1 1...

Page 30: ...6 28 1 5V 0 2V LOW DC 1 2...

Page 34: ...7 32 7 3 7 3 1 CBA 1500AT3 HC DSA V1...

Page 35: ...CMN023 005 Translation of the original instructions 33 12 7 2 7 2 31...

Page 36: ...34...

Page 69: ...MEMO...