Summary of Contents for CS-25V1A-H1; CS-35V1A-E2; CS-50V9A-S; CS-70V9A-T

Page 1: ...DC Inverter Split Air Condition Unit SERVICE MANUAL ...

Page 3: ...3 1 Air conditioning unit parameters ...

Page 6: ...6 ...

Page 8: ...8 The curve diagram of the compressor condensing pressure ...

Page 12: ...12 Capacity Correction Factor Due to Tubing Length One Way Cooling Heating ...

Page 13: ...13 Pressure Curve Suction Pressure Curve Discharge Pressure Curve ...

Page 15: ...15 4 Indoor and outdoor units size 4 1 outdoor Unit CS 25V1A H1 4 2 outdoor Unit CS 35V1A E2 ...

Page 16: ...16 4 3 outdoor Unit CS 50V9A S 4 4 outdoor Unit CS 70V9A T ...

Page 19: ...19 ...

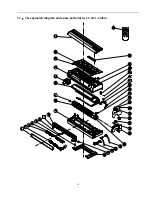

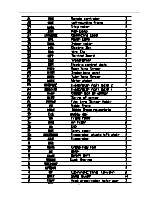

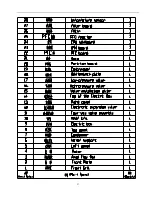

Page 20: ...20 5 2 The explosion diagram and spare parts list for CS 25V1A M81A ON OFF ...

Page 21: ...21 ...

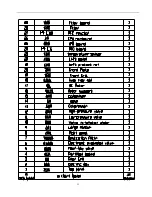

Page 22: ...22 5 3 The explosion diagram and spare parts list for CS 35V1A E2 ...

Page 23: ...23 ...

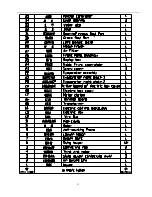

Page 24: ...24 5 4 The explosion diagram and spare parts list for CS 35V1A P81A ON 0FF F ...

Page 25: ...25 ...

Page 26: ...26 5 5 The explosion diagram and spare parts list for CS 50V9A S ...

Page 27: ...27 ...

Page 28: ...28 5 6 The explosion diagram and spare parts list for CS 50V9A S81A ON 0FF F ...

Page 29: ...29 ...

Page 30: ...30 5 7 The explosion diagram and spare parts list for CS 70V9A T ...

Page 31: ...31 ...

Page 32: ...32 5 8 The explosion diagram and spare parts list for CS 50V9A S ...

Page 33: ...33 ...