MWR

Installation Instructions

8

Display Installation

If the mounting pattern of the display being installed is a VESA

standard 200 x 200 pattern the mounting buttons can be

installed directly to the back of the display. If the display has any

other mounting pattern an interface bracket must be obtained

before proceeding. Consult a Chief Customer Service

representative if an interface bracket is required by calling

1-800-582-6480 or visit www.chiefmfg.com.

WARNING:

IMPROPER INSTALLATION CAN LEAD TO

MOUNT FALLING CAUSING SEVERE PERSONAL INJURY

OR DAMAGE TO EQUIPMENT. Displays can weigh in

excess of 40 lbs (18.1kg). ALWAYS use two people and

proper lifting techniques when installing display.

WARNING:

IMPROPER INSTALLATION CAN LEAD TO

MOUNT FALLING CAUSING SEVERE PERSONAL INJURY

OR DAMAGE TO EQUIPMENT. Make sure mounting buttons

on display are properly seated in mounting holes in faceplate.

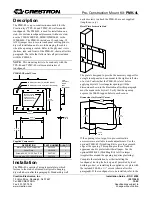

To install display:

1.

Move mount faceplate to extended position by grasping

faceplate and pulling outward away from wall.

(See Figure 6)

2.

While supporting both sides of display, align four mounting

buttons on display or interface bracket with four mounting

holes in faceplate. (See Figure 6)

3.

Lower display into place listening for audible "click" to

ensure recessed area of mounting buttons are properly

seated in lower area of mounting holes and "click lock"

mechanism has engaged. (See Figure 6) and

(See Figure 7)

Figure 6

NOTE:

Holes are provided in the faceplate for use with a

padlock or similar locking device, if desired. In addition,

the pin and nut may be removed from the upper holes

and moved to the lower holes for use as a more

permanent locking device. (See Figure 7)

Figure 7

CABLE MANAGEMENT

WARNING:

IMPROPER INSTALLATION CAN LEAD TO

SERIOUS PERSONAL INJURY OR DAMAGE TO

EQUIPMENT! Make sure cables do not run through pinch

points.

1.

Loosen front and rear cable clamps on top arm.

(See Figure 8)

2.

Thread cable ties (E) under cable clamps and secure

clamps to top arm. (See Figure 8)

3.

Route power/audio/video cables through the cable channel

in top arm (See Figure 8), allowing sufficient slack in cables

for left/Right movement of display and swing arm and also

swing arm extension and retraction.

4.

Secure cables to top arm using two cable ties (E).

5.

Repeat steps 1 through 4 for lower arm.

WARNING:

IMPROPER INSTALLATION CAN LEAD TO

SERIOUS PERSONAL INJURY OR DAMAGE TO

EQUIPMENT! DO NOT route cables through holes in

faceplate.

1

3

4

5

4

Remove pin

and nuts and

move to lower holes.

A padlock or bolt may

be placed through latch

holes