K2C2OFB215

Installation Instructions

6

Display Installation

The mounting holes on the back of the display will either be

flush with the back surface or recessed into the back surface.

Refer to the applicable installation procedure.

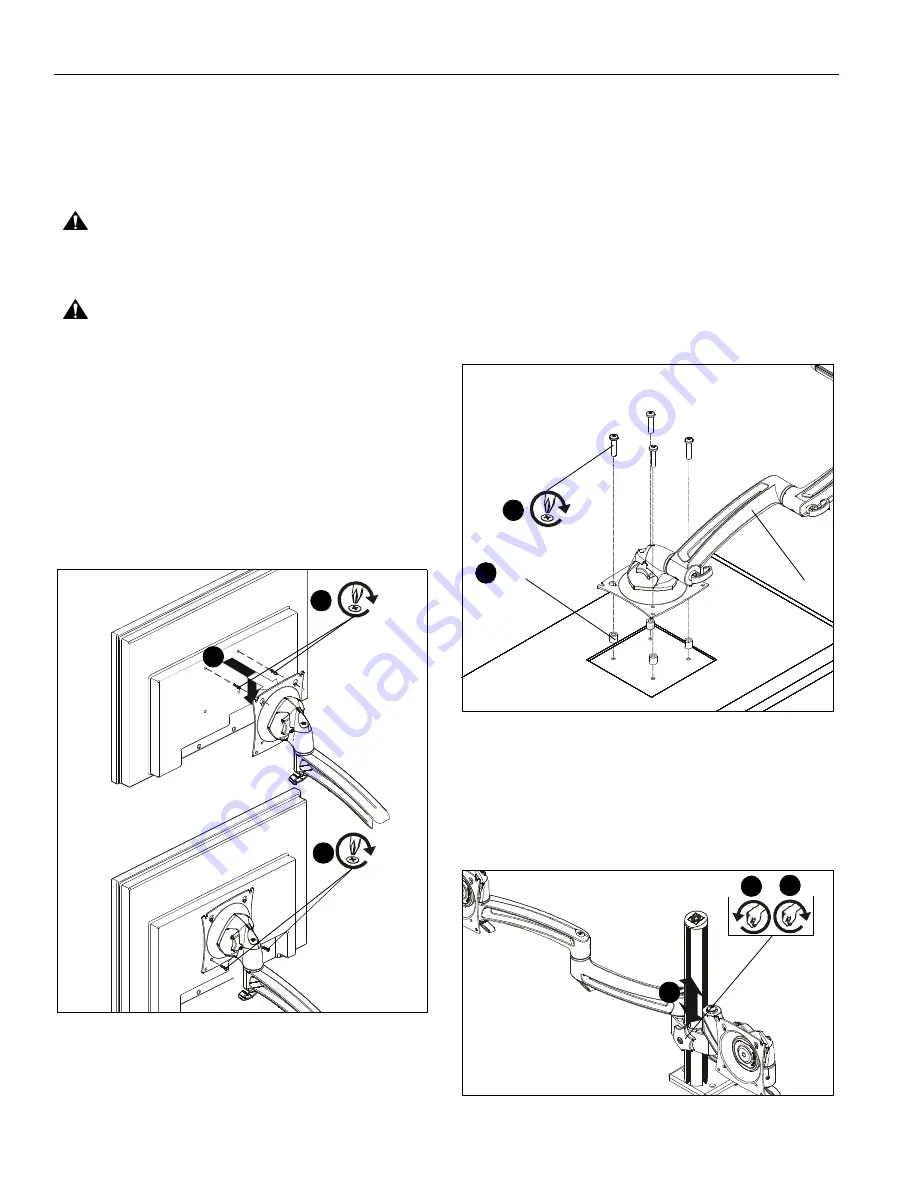

Flush Mounting Holes

CAUTION:

Using screws of improper size may damage

your display! Proper screws will easily and completely thread

into display mounting holes.

CAUTION:

Inadequate thread engagement in display may

cause display to fall! Back out screws ONLY as necessary to

allow installation of Centris bracket!

1.

Ensure faceplate is able to swivel and tilt easily, yet still be

tight enough to hold display in desired position. Adjust as

required before proceeding. See “ADJUSTMENT” for detail.

(See Figure 4)

2.

Using Phillips screwdriver, carefully install two M4x12mm

screws (B) into the

upper

mounting holes on the display.

Thread screws completely into display, then back out 3

complete turns. (See Figure 4)

3.

Pick up and align display so that screws (B) (installed on the

back of the display in the previous step) fit into the mounting

holes on the faceplate. Rotate the bracket as required.

Lower the display firmly into place. (See Figure 4)

Figure 4

4.

Using Phillips screwdriver, install two remaining M4x14mm

Phillips screws (B) through the

lower

mounting holes in

faceplate into the display. (See Figure 4)

5.

Tighten all four screws (B). Do not over-tighten!

Recessed Mounting Holes

1.

Ensure Centris bracket is able to swivel and tilt easily, yet

still be tight enough to hold display in desired position.

Adjust as required before proceeding. See “ADJUSTMENT”

for detail.

2.

Carefully place display face down on protective surface.

3.

Place the four spacers (D) over each of the mount holes on

the back of the display. (See Figure 5)

4.

Pick up and orient the mount (A) so that the mounting holes

are aligned with the holes in the spacers; rotate the bracket

as required. (See Figure 5)

5.

Using Phillips screwdriver, install four M4x25mm screws (C)

through the mounting holes, through the spacers and into

the display. (See Figure 5)

6.

Tighten all four screws. Do not over-tighten!

Figure 5

Adjustments

Column Height Adjustment

1.

Loosen column adjustment knob. (See Figure 6)

2.

Adjust height to desired level. (See Figure 6)

3.

Tighten column adjustment knob. (See Figure 6)

Figure 6

2

4

3

(D) x 4

5

(C) x 4

(A)

3

1

3

2