10

Towers

The PHOENIX repair system is equipped with pulling towers

that can be positioned 360 degrees around the machine.

The system can accommodate up to two additional towers.

All towers feature telescoping heads, adjustable collars,

and a unique roller assembly that not only secures the

tower to the bottom of the machine but also allows for 360

degree movement around the machine.

Also unique to this system are the “Sure-Lock” force

clamps that secure towers to circular pinning holes along

the outer edge of the mainframe. The force clamps secure

towers to the mainframe while removing stress from the

roller assemblies.

Tower pulls can be set up quickly and are controlled by a

hand-held pendant, which controls the flow of hydraulic

pressure, and individual tower valves which control the

flow of oil to each tower. Lateral and elevated pulling angles

can be made or changed in just a fraction of a minute.

CAUTION:

The 1/2 inch (13mm) tower chain

has a WLL: 20,000 lbs. (89kN).

To Operate Towers

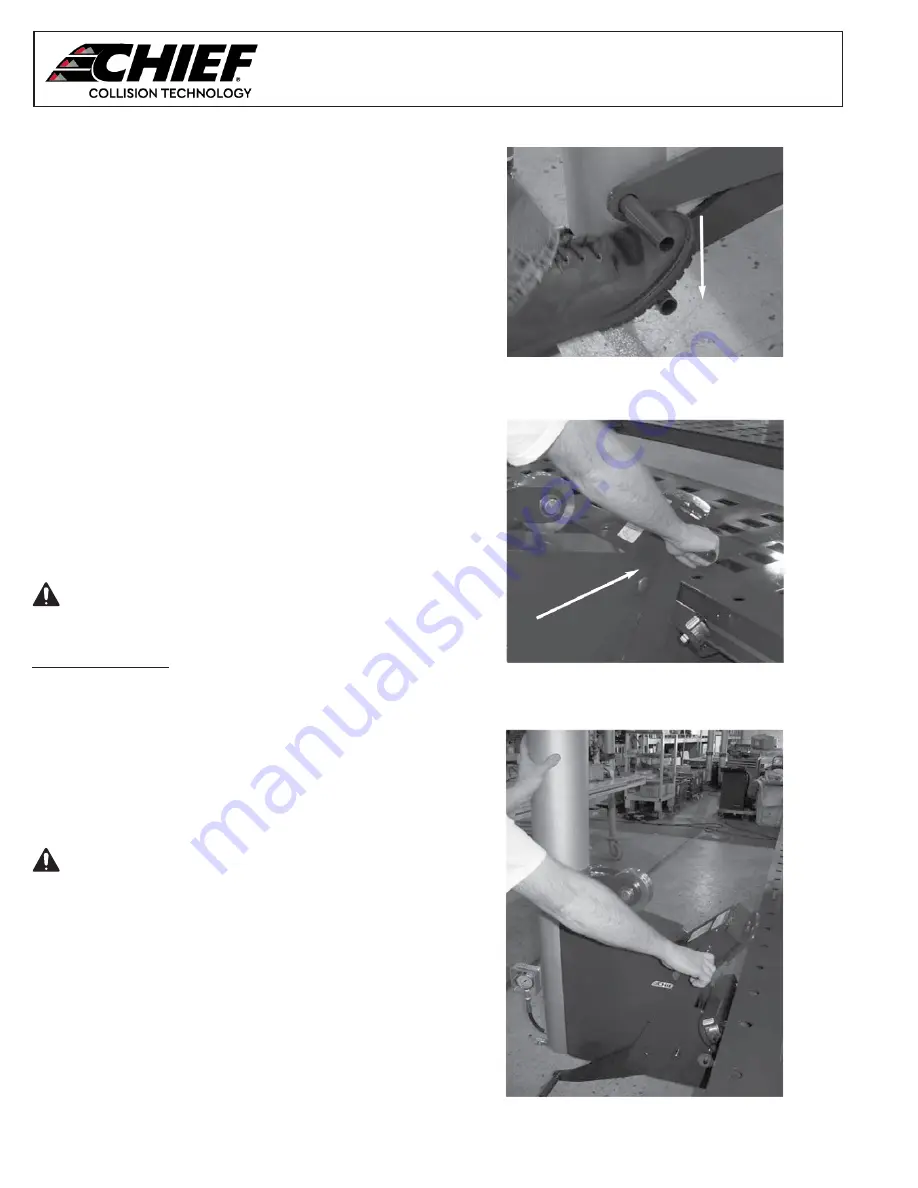

1. Step on “Sure-Lock” release handle to unlock

“Sure-Lock” force clamp from mainframe,

Figure 4.

2. Rotate “Sure-Lock” lock handle forward to fully

open Sure-Lock, Figure 5.

3. Push tower to desired location on machine,

Figure 6.

CAUTION:

When pushing tower, keep one hand on

“Sure-lock” lock handle and other

hand on tower pipe above collar. Also,

keep hands away from all pinch

points...i.e. roller assemblies on bottom

of mainframe plate and force clamp

pinning locations on top mainframe

plate.

Figure 4

Figure 5

Figure 6

PHOENIX

USERS MANUAL