Page 9

For technical questions, please call 1-888-866-5797.

Item 62422

Operating Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section

at the beginning of this manual including all text under

subheadings therein before set up or use of this product.

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION:

Turn the Power Switch of the tool off and unplug the tool from its

electrical outlet before adjusting tool or installing accessories.

Work Piece and Work

Area Set Up

1. Designate a work area that is clean

and well-lit. The work area must not

allow access by children or pets to

prevent distraction and injury.

2. Route the power cord along a safe route

to reach the work area without creating a

tripping hazard or exposing the power cord

to possible damage. The power cord must

reach the work area with enough extra length

to allow free movement while working.

3. Secure loose work pieces using

a vise or clamps (not included) to

prevent movement while working.

4. There must not be objects, such as

utility lines, nearby that will present

a hazard while working.

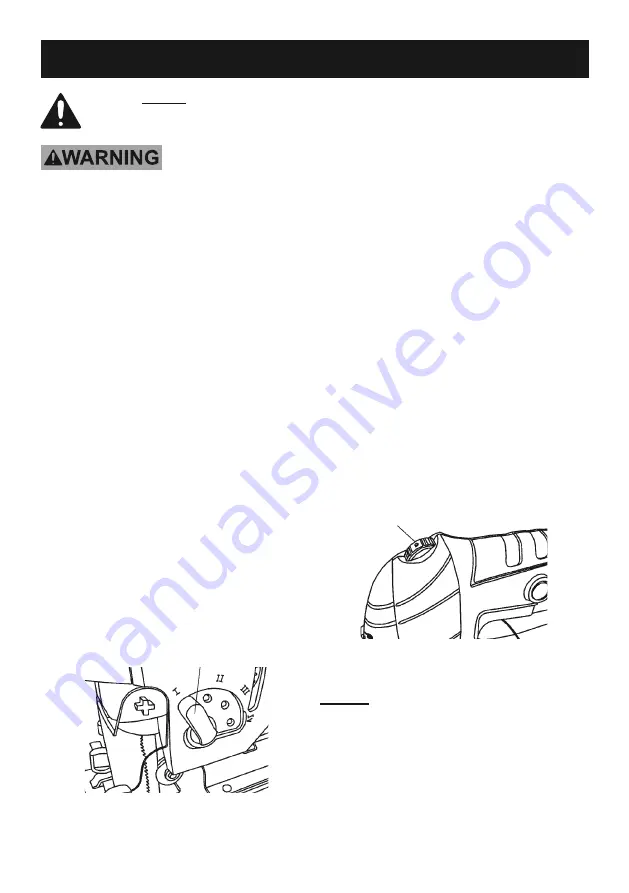

Selecting Cutting Mode

1. The Jigsaw comes with four cutting modes

(three cutting settings and 1 straight cutting

mode). To change cutting mode, adjust the

Orbital Mode Lever (16). See Figure 2, below.

Figure 2

Orbital Mode Lever (16)

2. The settings are:

a. I = Straight line cutting (for

plastics and mild steel)

b. II = Small orbit (for aluminum

and hard wood)

c. III = Medium orbit (for wood, plywood

and fast cutting of aluminum)

d. IV = Large orbit (for fast cutting

wood and plywood)

Adjusting Jigsaw Speed

1. The Jigsaw’s speed can be adjusted between

500 and 3,000 strokes per minutes.

2. To adjust speed, turn the Speed Switch from

1 (the slowest speed) to 6 (the fastest speed).

See Figure 3, below.

Figure 3

Speed Switch

3. Use higher speeds to cut work pieces faster.

NOTICE:

Refer to the Blade Selection

chart on page 7 to verify you are using the

correct speed with the appropriate blade.

Otherwise blade damage can occur.