Page 13

For technical questions, please call 1-888-866-5797.

Item 61608

Operating Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section

at the beginning of this manual including all text under

subheadings therein before set up or use of this product.

Tool Set Up

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION:

Turn the Power Switch of the tool off and unplug the tool from

its electrical outlet before performing any procedure in this section.

TO PREVENT SERIOUS INJURY:

DO NOT OPERATE WITH ANY GUARD DISABLED, DAMAGED,

OR REMOVED. Secure the Table in place before operation.

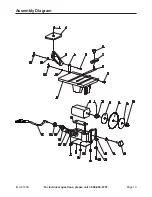

Blade Installation

1. Loosen the Table Knob and remove the Table.

2. Use one wrench to hold the Arbor Bolt and

another wrench to loosen the Arbor Nut.

3. Slide a Blade Shim onto the Arbor, then

a Blade (with the Blade’s arrow matching the

label’s arrow), and the other Blade Shim.

4. Replace the Arbor Nut and

wrench tighten it securely.

5.

WARNING! To prevent serious injury,

replace the Table after service and secure

firmly in place using the Table Knob.

6.

WARNING! To prevent electric shock,

do not use for wet cutting.

Arbor

Nut (15)

Arbor

Bolt (12)

Blade (13)

Figure B: Blade Installation

Depth Adjustment

1. Replace the table on the base,

allowing the Blade to emerge

through the Table′s Blade Slot.

2. Make sure the Table Knob Slot

is over the Table Knob.

3. For deepest cutting, allow the Table

to rest fully on the Motor.

4. Tighten the Table Knob, and

check the Table′s stability.

5. For shallower cutting, gently lift the Table

up to reduce the portion of the Blade

that appears through the Blade Slot.

6. Adjust the Table, up or down, according

the desired depth of cutting.

7. When that desired depth is achieved,

tighten the Table Knob.

8. After adjustment, check the Table′s stability.