1997/98 Chevrolet Corvette

Collision Repair

3-35

Rear Bumper Impact Bar

,,

,

,

,

,,

,

,

View A

40mm

50mm

15mm

30mm

50mm

40mm

View A

C of

vehicle

L

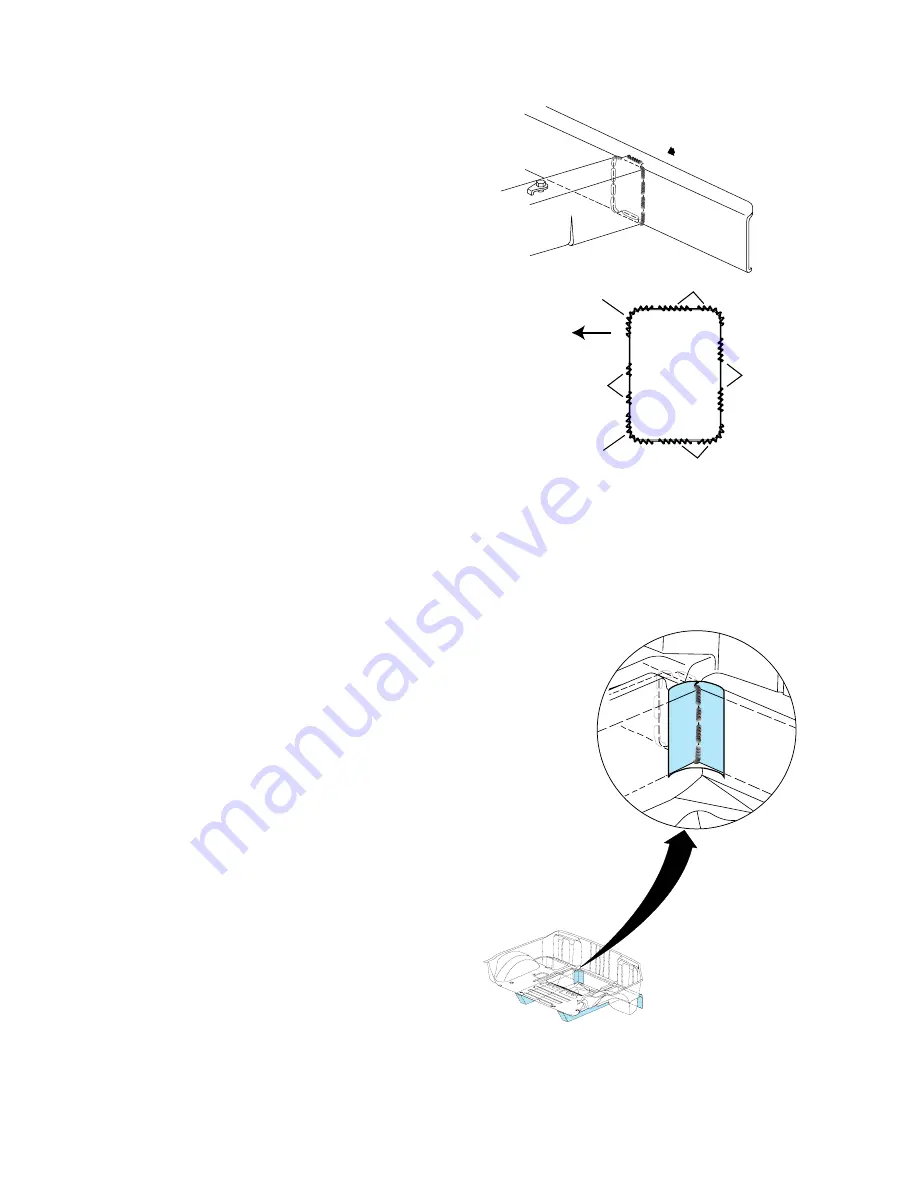

Fig.␣ 3.74 — Weld Perimeter of Joint, as Indicated

,

,,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

,

Fig.␣ 3.75 — Prime Bare Metal Areas

Before Installing Window Cutouts

2

Temporarily position the impact bar and

scribe lines into the primer indicating where

the welds will be made. Remove the primer

from the areas to be MIG welded by sanding

with 80-grit paper on a ‘Dual-Action’ sander

(DA). Do Not use a grinder to remove the

primer.

3

Prepare all bare metal surfaces and apply

weld-through primer as necessary. Be sure to

apply primer to the inside of the ‘fishmouth’

area also.

4

Position the bumper impact bar using

three-dimensional measuring equipment and

install per the original weld locations. Stitch

weld around the ‘fishmouth’ joint. If not trace

of the original welds are present, use

Fig.␣ 3.74 as a guide for welding the side rails

to the impact bar. This weld pattern will

create a solid weld joint with minimal heat

distortion.

5

Clean and prepare all welded surfaces,

use 3M’s Scotch-Brite Clean-N-Strip Discs

(disc P/N 07460, mandrel P/N 07491), or

equivalent (Fig.␣ 3.75).

Important: Prior to refinishing, refer to

GM P/N 4901 Refinish Manual for

recommended products.

6

Apply approved anti-corrosion primer.

Notice: DO NOT top-coat any bonding

surfaces.

Notice: Top surface of impact bar (where

it is to be bonded to the rear

compartment panel), must not be

top-coated, see Fig.␣ 3.73. The bonding

area must remain a ‘primer only’ surface

7

Apply 50mm (2 inch) wide tape over the

‘windows’ cut in the rear compartment panel,

from outside the vehicle. Apply adhesive to

the inside of the tape backer, and install the

previously cut-out pieces in their original

locations (Fig.␣ 3.76). (

Refer to SMC repair

procedures.)

Important: Use US Chemical and Plastics

82014B System 2000 Structural Adhesive,

a PLIOGRIP

®

adhesive manufactured by

Ashland Chemical Company, or equivalent.

Note the 9 minute working time and 1

hour cure time.