Setup

ILS-606 & ILS-625 User Manual

7

2005-03-09/22:45

Hanging Bracket

Note!

Clamp is sold separately.

OU TPU T

IN P UT

PIN 1 - CO MM

PIN 2 - DM X -

PIN 3 - DM X +

M IC

S EN S ITIV ITY

ON LY FOR

R EM OTE C ON TR OL

CON F I GU RAT I ON

CH 1 =PA N

CH 2 =T I LT R OT AT I ON

CH 3 =S HU T T ER / SH AK IN G

CH 4 =G OBO

CH 5 =C OL OR

CH 6 =G OBO R OTAT I ON

CH 7 =D I MM ER

PO WER

FU SE

Q

C

P

A

S

S

E

D

Mo d el:

Se r ial N o:

Po w er :

F use :

Bu lb:

D is c onne c t pow e r a nd wa it 5 m in. be fo re ope ning .

A djus t la m p p os itio n by tur nin g s c r e ws A ,B a nd C .

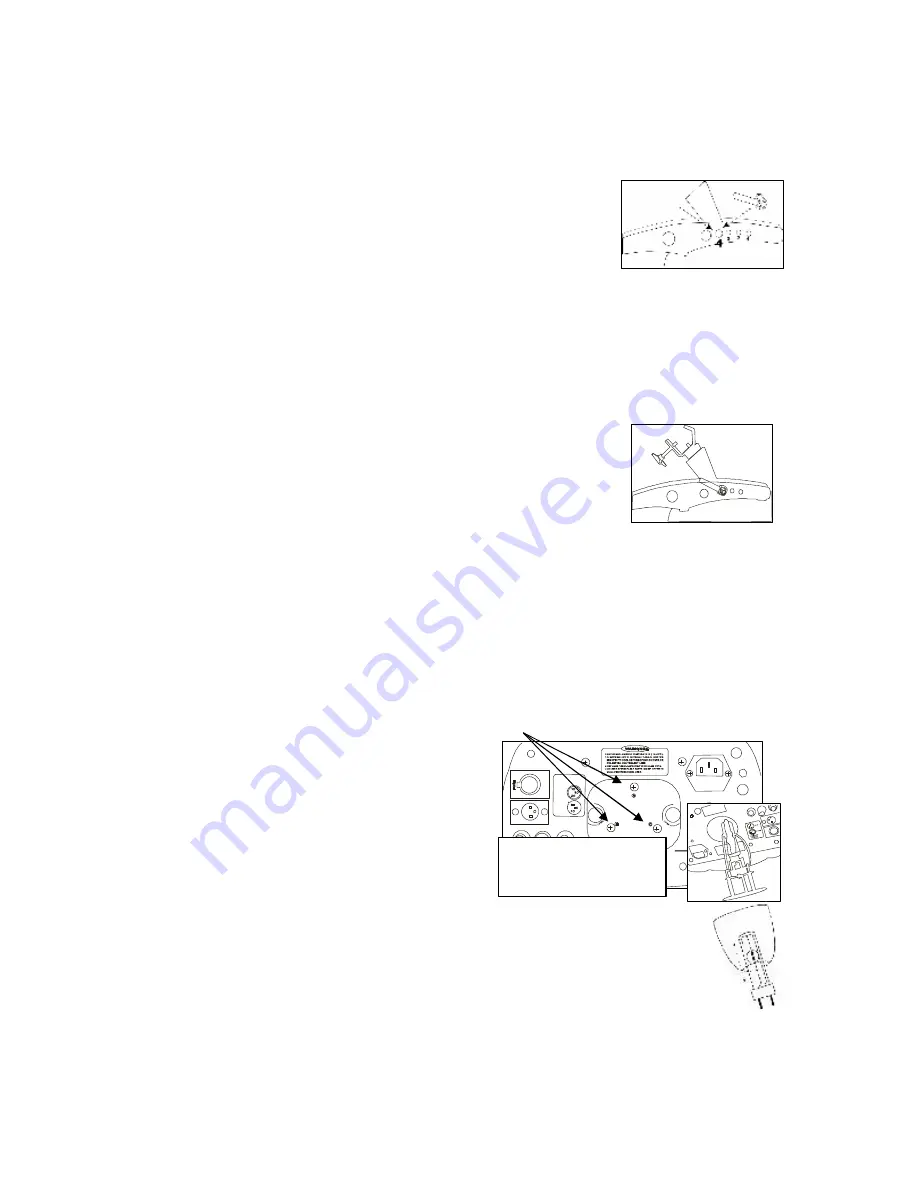

Lamp alignment screws

Even out this plate by turning the

lamp alignment screws, prior to

lamp optimization. This will

provide you a good starting point.

Mounting

H ANG I NG BRACKE T & F IXT URE F LO O R STANDS

Mount the hanging bracket on the fixture as illustrated on the right. The

tension knob is unique in that it is self ratcheting, providing you tool-free

tensioning of the bracket. Pull knob handle towards you and turn either to

apply tension or to release tension. Also included are two fixture floor

stands and a convenient hex wrench tool for fastening them. The wrench

also opens the fixture

’

s front and back covers

.

O RI E NT AT I O N

This fixture may be mounted in any position provided there is adequate room for ventilation. It is also

possible to stand this fixture using the removable floor stands.

RI G G I NG

It is important never to obstruct the fan or vents pathway. Mount the fixture

using, a suitable

“

C

”

or

“

O

”

type clamp. Adjust the angle of the fixture by

loosening both knobs and tilting the fixture. After finding the desired

position, retighten both knobs.

When selecting installation location, take into consideration lamp

replacement access and routine maintenance.

Safety cables should always be used.

Never mount in places where the fixture will be exposed to rain,

high humidity, extreme temperature changes or restricted ventilation.

Lamp Alignment

L AM P AL I G NM E NT HO W-T O

Often, after a new installation of a lamp, you will find that there is an uneven field of light or what is referred

to as a hot spot. This is due to the most intense point of the lamp source not being positioned optimally

within the reflector.

There are three lamp alignment screws provided

at the base of the fixture. Turning these screws

allow you to optimize the projection quality of the

spot as well as the overall intensity of the beam.

1)

Project a white spot against any flat

surface. Preferably the surface should be

white or pastel in color.

2)

Turning the lamp alignment screws, try to

position the hot spot in the center of the

beam as best as possible. This could

require many attempts on your part. It is advisable to even out the screws prior to

lamp alignment as described in the illustration.

3)

Once the hot spot is in the center of the spot, do your best to turn all screws equally as

to affect movement up or down within the reflector.

4)

As you move in and out of optimum lamp focus, you will see the hot spot either get wider

or narrower. The goal is to either totally diminish the hot spot by having it widen and

spread across the entire spot or moving the hot spot so that it covers as much of the beam

spot area as possible.