First Time Use

Read your Assembly Manual and ensure the grill is put together

properly. Remove all Point-of-Purchase advertising material from

all grill surfaces before first use. We recommend operating your

grill on its highest setting for 15-20 minutes prior to your first use.

This aids in removing the oils used during manufacturing.

Lava Rock / Briquettes

This gas grill has been designed, engineered, and tested to be

used with flame tamers or heat distribution plates to provide

more even heating, improve the cleaning process, and reduce

flare-ups. The addition of after market lava rocks, charcoal, or

briquettes of any type will cause poor combustion and increase

the likelihood of a grease fire, and is not recommended. Using

briquettes, lava rock, or charcoal in this grill will void your

warranty. For extra smoke flavor, we recommend using a

smoker box with wood chips.

Temperature

The temperature gauge in the hood of your new grill measures

air temperature. The air temperature inside your grill will never

be as hot as the temperature at the cooking surface.

Note: Since 1995, all regulators (the part that attaches to the gas

tank to regulate the flow of gas) have included a safety feature

that restricts gas flow in the event of a gas leak. You can

inadvertently activate this safety feature without having a gas

leak. This typically occurs when you turn on the gas using the

grill control knob before you turn on the LP tank valve. If the gas

regulator safety feature activates, the grill will only reach

temperatures between 250°F and 300°F even with all burners on

the high setting.

If your grill is not getting hotter than 250°F to 300°F these

steps should be taken first to reset the gas regulator safety

device:

1. Open the grill lid.

2. Turn off all knobs on the control panel in front.

3. Turn off the tank knob.

4. Disconnect the regulator from the LP tank.

5. Wait 30 seconds.

6. Reconnect the regulator to the LP tank.

7. Slowly open the LP tank knob all the way. Do not put

excessive force on the valve at the full open position to avoid

damaging the valve.

8. Turn on the appropriate control knob and light the grill per the

instructions on the control panel.

An illustration of this process is included in this Product Guide.

See Troubleshooting section for additional information.

Pre-Heating Your Grill

Just like your home oven, your grill should be pre-heated to

provide optimum performance. Pre-heat the grill on high for 10-

15 minutes – longer if weather conditions require. Please refer to

the lighting instructions inside the Product Guide if you have

questions about how to light your grill. A match-light chain and

hole is provided for your convenience.

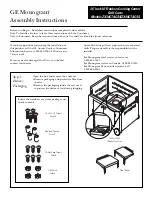

GRILLING GUIDE – Getting Started

Regulator

Coupling Nut

4

Summary of Contents for 466270311

Page 30: ...NOTES 30...

Page 31: ...31 Warranty Registration Department P O Box 1240 Columbus GA 31902 1240...

Page 32: ......