17

ASSEMBLY

1

2

CAUTION: When unpacking grill components, two people should raise grill head from the shipping box.

ASSEMBLY

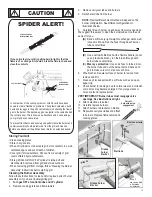

Take the leg assembly out from the shipping box, place it as shown.

Place bottom shelf to bottom shelf brace.

Tighten the pre-installed screws to bottom shelf.

Bottom Shelf

Right Leg Assembly

Left Leg Assembly

Summary of Contents for 463211511

Page 28: ...NOTES 28 ...

Page 29: ...NOTES 29 ...

Page 30: ...30 NOTES ...

Page 31: ...Warranty Registration Department P O Box 1240 Columbus GA 31902 1240 31 ...

Page 32: ......