12

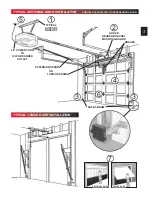

FIG. 2-4

Adding mounting surface

.

[22]

Doors made of masonite, lightweight wood, fiberglass, and

sheet metal must be properly braced before mounting door

operator. Contact door manufacturer or distributor for a bracing

kit. The Overhead Door Corporation is not responsible for

damage caused due to improperly braced door.

(Fig. 2-6)

CAUTION

FIG. 2-5

Header bracket in place (3 methods)

.

FIG. 2-6

Examples of door bracing

.

FIG. 2-7

Mounting door Bracket (sectional)

.

[42]

Carriage bolt & nut.

preferred

1

2

3

FIG. 2-7B Mounting door Bracket (one-piece).

on top edge

at top of back

bolted to studs in wall

NO SLOT

1/4" x 2"

1/4"-20 x 3/4"

even with or

above top roller

[22]

1/4" x 2"

NOTE

: If header bracket location needs to be

above header for garage door opening, you need to

add a “mounting surface.” A 2" x 6" board securely

attached (fasteners not included) across wall studs

on either side of your mark is sufficient

(Fig. 2-4)

.

OPEN ORANGE PARTS BAG

2. Mounting the header bracket

.

NOTE

: Although header bracket may be oriented

several ways, method 1 is preferred if possible

because of added strength over other methods

(Fig. 2-5)

.

•

Hold header bracket against wall

(Fig. 2-5)

.

–

Place left edge on vertical line.

–

Bottom edge on final height line.

•

Mark screw hole locations on wall.

•

Drill 5/32" pilot holes at each screw hole mark.

–

Fasten header bracket with 3 lag screws (22)

(Fig. 2-5)

.

DOOR BRACKET:

3. Finding door bracket mounting location

.

•

Door bracket is mounted as high on door as

possible along vertical centerline.

NOTE

: In the case of

sectional type

doors, door

bracket must be mounted NO LOWER THAN top set

of rollers

(Fig. 2-7)

.

For

1-piece

doors, door bracket must be mounted at

top edge of door.

4. Mounting the door bracket

.

•

Proper bracing should be verified at this point.

–

Align door bracket centered on your

vertical centerline.

–

Attach using 3 self-drilling screws (42).

–

Use

lag screws

(22) for

solid wooden doors.

NOTE

: For solid wood doors, carriage bolts

WITHOUT SLOTTED HEADS (not included, but

available by calling the Overhead Door help line) may

be used for attaching door bracket.