24

RESETTING FACTORY DEFAULTS - CLEARING MEMORY

To reset most of the user installed settings back to factory

defaults:

1. Turn the selector dial to DIAGNOSTIC.

2. Press and hold the STOP button for 5 seconds. The MAS LED

will flash momentarily when the factory defaults have been

restored.

3. Return the selector dial to the desired wiring type.

Factory Defaults:

a. Timer to close = 0 seconds

b. CPS-L photo eyes = unlearned

c. The Mid Stop is deactivated

d. The Maintenance Alert System is deactivated

e. The Maximum Run Timer is set to 90 seconds

f. Dealer Mode is deactivated

g. Restoring the operator to Factory Default will also disable this

feature. The remote controls will still be learned.

NOTE:

Life of Operator feature (Odometer/Cycle Counter) and

programmed remote controls are not cleared.

Operation will vary

depending on

wiring type

SELECTOR DIAL

O P T I O N A L P R O G R A M M I N G

RED/GREEN WARNING LIGHT CARD

Feature:

The Red/Green warning light card flashes a warning light

for 10 seconds prior to the Timer to Close activating the door to

close.

Benefit:

Advanced warning of the door closing helps prevent

traffic collisions with the door.

Light Control Module Operation:

The green lights on the OPTION

BOARD will turn on if the board is seated properly and the power

is on. When the door reaches the full open limit or mid stop, the

timer circuit and the green lamp holder will be activated. (Green

lamp will not be activated if timer setting is less than 10

seconds.) The red lamp holder will receive power as indicated at

right.

Requirements:

Must have the LiftMaster Red/Green warning light

kit RDGRNCARD and must have at least one of the following

safety devices attached: CPS-L, CPS-LN4 or CPS3. See

Red/Green warning light instructions for further details.

TIMER SETTING

RED LAMP HOLDER RECEIVES POWER

Timer setting equals

zero

Activates when the door closes and until

close limit is activated

Greater than 10

seconds

10 seconds before door starts to close

and until close limit is activated

Less than or equal to

10 seconds

Activates when the door reaches the

open limit or mid stop

The red lamp holder receives power

when the door opens and remains

activated if the door is stopped manually

before reaching the mid stop or the open

limit

Summary of Contents for H

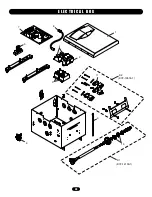

Page 30: ...30 E L E C T R I C A L B O X 1 4 7 6 10 5 2 11 K2 K1 3 9 8 K72 12515 1 K72 14130 1 ...

Page 32: ...32 M O D E L J 12 14 16 15 13 3 8 10 2 9 11 2 1 4 3 7 5 6 6 K1 K2 K72 19975 K72 19974 ...

Page 34: ...34 M O D E L H 19 15 14 11 2 16 17 18 10 9 4 3 1 12 7 7 13 5 6 2 8 K1 K2 K72 19974 K72 19979 ...

Page 38: ...38 O P E R A T O R N O T E S ...

Page 39: ...39 O P E R A T O R N O T E S ...