11

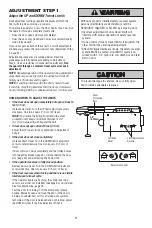

INSTALLATION STEP 5

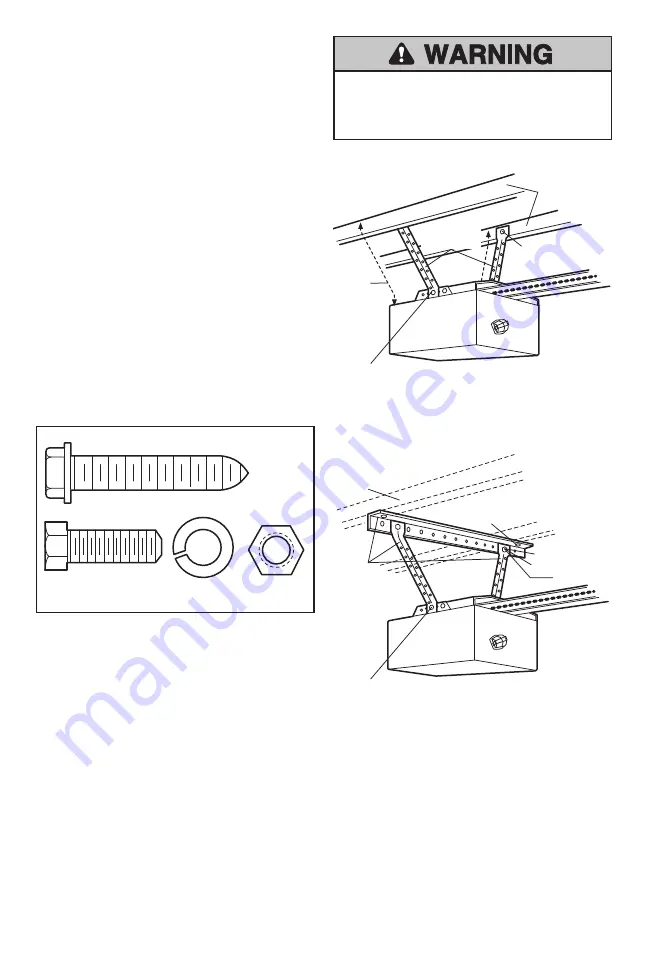

Hang the Operator

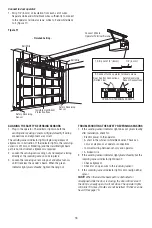

Two representative installations are shown. Yours may be

different. Hanging brackets (not provided) should be angled

(Figure 1) to provide rigid support. On fi nished ceilings

(Figure 2), attach a sturdy metal bracket to structural supports

before installing the operator. This bracket and fastening

hardware are not provided.

1. Measure the distance from each side of the motor unit to

the structural support.

2. Cut both pieces of the hanging bracket to required lengths.

3. Drill 3/16" pilot holes in the structural supports.

4. Attach one end of each bracket to a support with

5/16"-9x1-5/8" lag screws.

5. Fasten the operator to the hanging brackets with

5/16"-18x7/8" hex bolts, lock washers and nuts.

6. Check to make sure the rail is centered over the door (or in

line with the header bracket if the bracket is not centered

above the door).

7. Remove the 2x4. Operate the door manually. If the door

hits the rail, raise the header bracket.

NOTE

: DO NOT connect power to operator at this time.

Figure 1

Figure 2

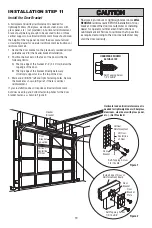

To avoid possible SERIOUS INJURY from a falling door

operator, fasten it SECURELY to structural supports of

the door. Concrete anchors MUST be used if installing

ANY brackets into masonry.

HARDWARE SHOWN ACTUAL SIZE

Lag Screw 5/16"-9x1-5/8"

Hex Bolt

5/16"-18x7/8"

Lock Washer

5/16"

Nut

5/16"-18

Hex Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

Hex Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

Hidden Support

Brackets

(Not Provided)

Measure

Distance

- FINISHED CEILING -

Lag Screws

5/16"-9x1-5/8"

Structural

Supports

Lag Screws

5/16"-9x1-5/8"

(Not Provided)

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

Brackets

(Not Provided)

Summary of Contents for ATS 2113X 1/2 HP

Page 35: ...35 NOTES ...

Page 71: ...35 REMARQUES ...