Cetetherm AquaEfficiency

Installation, service and operating instruction

7

Flowcharts

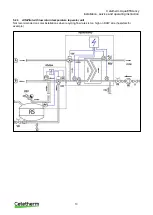

The tap water modules should be installed according to the following schematics.

Whatever type, unit model and production type (Instantaneous or Semi Instantaneous), each

pump (or pump motor when double ones) delivers 10% to 100% of the nominal primary pump

signal and 25% to 100% of the nominal secondary pump signal, to stick to the actual demand.

Cetetherm do not recommend the use of a mixing bottle on primary side of an AquaEfficiency installation,

because the mixing effect destroys the low return temperature. But the need for the differential pressure

breaker functionality of this mixing bottle is still mandatory.

On AquaEfficiency Cetetherm recommends replacing the traditional mixing bottle by a small buffer tank, named

STBI, that serves as an inertial storage tank and avoids any boiler pumping.

In case a primary vessel, named STP, is required or designed on the installation, the STBI tank becomes

unnecessary.

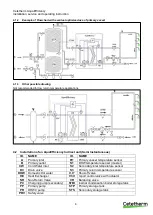

4.1

Installation of an AquaEfficiency Direct unit

ID.

NAME

ID.

NAME

A

Primary inlet

Pt1

Outdoor temperature sensor

optional, for heating purposes

B

Primary outlet

S1

DHW temperature sensor (master)

CW

Cold Water inlet

S2

Secondary inlet temperature sensor

DC

Drain valve

S3

Primary return temperature sensor

DHW

Domestic Hot water

V, V’

Shut-off valve

HE

Heat Exchanger

V3V

3-port control valve with actuator

NR

Non Return Valve

VR

Balancing valve

PP

Primary pump

STBI

Inertial condensation boiler storage tank

PR

DHWC pump

STP

Primary storage tank

PRV

Safety valve

STS

Secondary storage tank

4.1.1

Standard flowchart for Direct version