SKU

97525

Page

7

For technical questions, please call 1-800-444-3353.

Anytime any maintenance or repairs are done (including clearing jams), FIRST:

1. Disconnect the Nailer/Stapler from the air hose.

2. Empty Magazine A (61) completely.

3. Attempt to fire the Nailer/Stapler into a piece of scrap wood to ensure that it is

disconnected and is incapable of firing any staples.

4.

Always leave Magazine A (61) open during maintenance. The Magazine is spring-

loaded and may cause parts or a fastener to fly out of the Nailer/Stapler.

Clearing Jams

1. Disconnect tool from air hose, empty Magazine A

(61) of fasteners, release any built-up air pressure,

and leave the magazine open, as explained above.

2.

While doing this step and the next 2 steps, hold the

Nailer/Stapler pointed away from you and any other

people or fragile objects - see

Figure 1

. Remove all

three Safety Cover Bolts (48) on the Safety Cover

(47) - see

Figure 2

.

3. Lift the Safety Cover (47) off the top of the Nailer/

Stapler - see

Figure 3

.

4. Carefully slide the Driver Cover (50) off around the

Safety (42). Note the position of the tab on the Driver

Cover (50). Remove the jammed fastener; pliers

may be necessary to remove a stuck fastener.

5. Inspect the Driver (17A) for bends or breakage. If

it is damaged, do not use the tool until it is repaired

by a qualified technician.

6. Lightly oil the Driver (17A) and replace the Driver

Cover (50) with the tab in the Cover facing the Driver

Guide (52). Replace the Safety Cover (47), being

careful to line up the bolt holes and fit the Safety

(42) into the slot. Replace and securely tighten all

of the Safety Cover Bolts (48). Make sure that the

Safety (42) moves without sticking.

7. Reload the Nailer/Stapler.

8. Reconnect the Nailer/Stapler to the air hose.

9. Press the Safety (42) of the Nailer/Stapler against

an appropriate piece of scrap wood.

10. Test fire the Nailer/Stapler several times, checking

for proper operation.

11. Disconnect the Nailer/Stapler, remove the fasteners,

and store the Nailer/Stapler in a location out of

children’s reach.

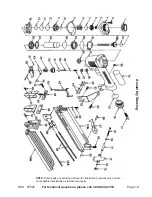

FIGURE 1

FIGURE 2

Safety

Cover (47)

Safety Cover

Bolts (48)

FIGURE 3

Safety

(42)

Safety

Cover (47)

FIGURE 4

Safety

Cover (47)

Driver

Cover (50)

tab