Page 14

For technical questions, please call 1-800-444-3353.

Item 56101

Changing Oil

1. Place a container under the Drain Plug.

2. Remove the Oil Plug to allow air flow into the Pump.

3. Remove the Drain Plug, allowing the

oil to drain into the container.

4. When the oil is completely drained from

the Pump, replace the Drain Plug.

5. Fill the Pump with new compressor oil to

the FULL level on the Oil Sight Glass.

6. Replace and tighten the Oil Plug.

7. Discard the old oil according to local,

state and federal regulations.

Draining Moisture from the Tank

The Drain Valve is located under the Tank. It must be

accessed daily to release all trapped air and moisture

from the Tank. This will eliminate condensation which can

cause tank corrosion. To empty the air and condensation:

1. Make sure the compressor engine is off.

2. Place a collection pan under the Drain Valve.

3. Open the Drain Valve by pivoting the lever

on the bottom of the Compressor so the

lever is in line with the Drain Valve.

4. When all the pressure is released, close

the Drain Valve by pivoting the lever on the

bottom of the compressor so that the lever

is perpendicular to the Drain Valve.

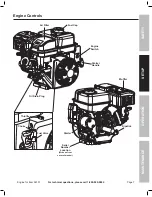

Air Filter Maintenance

Check the Air Filter weekly to see if it needs replacement.

If working in dirty environments, you may need to

replace the filter more often. To replace the Air Filter:

1. Unthread the Wing Nut holding the

Air Filter Assembly in place.

2. Remove the Air Filter Assembly.

3. Replace with a new Air Filter.

4. Secure in place with the Wing Nut.

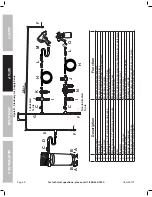

Adjusting Belt Tension

1. Remove the Belt Guard Cover (129) and set it aside.

2.

Deflection

Distance

Press on the center of the longest span on

each belt with moderate finger pressure

(4-4.5 lb.). Then measure the deflection

distance, the distance that the belt moved.

The belt should deflect anywhere from 1/2″ to 1″.

Bottom Plate (114)

Nut (115)

Threaded Rod

(118)

Bolts (110)

Engine

Mounting

Bolts

Engine Base

3.

If either belt deflects too much,

tighten belts by

loosening the four Bolts (110) on the Bottom Plate

(114) and moving the engine away from the other

pulley slightly by turning the Nut (115) holding the

Threaded Rod (118). Secure engine mounting bolts

and retest tension. If either belt is too long to be

properly tensioned, both belts must be replaced.

4.

If either belt deflects too little,

loosen belts by

loosening the Bolts on the Bottom Plate and moving

the engine towards the other pulley slightly by

turning the Nut (115) on the Threaded Rod (118).

Secure engine mounting bolts and retest tension.

5. Before use, replace belt cover.

SAFETY

OPERA

TION

MAINTENANCE

SETUP