SKU 97524

40116

Page 9

For technical questions, please call 1-800-444-3353.

Maintenance

Warning!

Always disconnect the tool from the air compressor and then empty the magazine

of nails or staples before attempting to inspect or perform maintenance to the Nailer/

Stapler.

1. Inspect all of the nuts and screws and make sure they are securely fastened.

2. Periodically lubricate the driving mechanism and magazine with a light oil. Wipe down

with a clean cloth. Never use gasoline or flammable solvents to clean the tool.

3. Inspect your air compressor according to manufacturer’s instructions.

Warning!

If you detect any air leaks, power loss, the Nailer/Stapler skips driving, drives too

deep, or not deep enough, take the Nailer/Stapler to a qualified service technician.

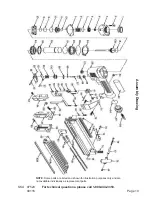

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL

AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS

OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT

ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED

TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING

OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR

ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Parts List

Part Description

1

Exhaust Deflector

3

Hex. Bolt

4

Head Cap

5

Seal

6

Internal Lining

7

O-Ring

8

Compression Spring

9

Gasket

10 O-Ring

11 Head Valve Piston

12 O-Ring

13 O-Ring

14 O-Ring

16 O-Ring

17A Piston & Driver

26 Body

27 Nozzle

35

Compression Spring

37 Spring Pin

38 E-Ring

Part Description

39 Trigger

40 Retainer Pin

41 Safety Guide

42 Spring Washer

43 Hex Bolt

44 Spring Pin

45 Spring

46 Screw Nut

47 Thumb Wheel

48 Spring

49 Steel Ball

50 Stopper

51 E-Ring

52 Safety

53 Safety Cover Bolt

54 Safety Cover

55 Hex. Bolt

56 Spacer

57 Driver Cover

58 Driver Guide

59 Hex. Bolt

60 Pin

Part Description

61A Magazine B

62A Steel Bar

63 Pusher Unit

64 Spring Holder

66 Spring

67A Magazine A

68 Stopper

69 Hex. Bolt

70 Hex. Bolt

71A Nail Positioner

72 Retaining Pin

73 Latch

74 Spring

75 O-Ring

76 Hex Bolt

77 Cylinder Pin

78 Tail Cover

79 Hex. Bolt

80 Hex. Bolt

81 Tail Hanger

82 Lock Nut

83 Hand Grip

Part Description

84 O-Ring

85 End Cap

86 Air Plug

87 Collar

88 Fixed Ring

89 O-Ring

90 Lining Ring

91 O-Ring

92 Cylinder

93 Lining Ring

94 Bumper

95 Seal

96

Trigger Valve Upper

97 Trigger Plunger

98 O-Ring

99 O-Ring

100

Trigger Valve Lower

101 Trigger Plate

102 Non-mar Tip