SKU 97524

40116

Page 5

For technical questions, please call 1-800-444-3353.

Unpacking

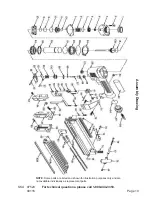

When unpacking, check to make sure the parts listed on page 9 are included. If any parts

are missing or broken, please call Harbor Freight Tools at the number on the cover of this

manual as soon as possible.

Testing The Single Sequential Safety Trip Mechanism

Warning: Even though the nailer should be empty during this procedure, ALWAYS point

the nailer/Stapler at a piece of scrap wood when testing.

1. The Nailer/Stapler should not fire if the nose is not depressed against the workpiece.

This tool has a contact safety tip mechanism, which is designed to prevent inadvertent

firing. The tool will only fire if the Safety (52) is resting on the workpiece prior to pulling

the Trigger (39).

2. Make sure the tool is disconnected from the air supply.

Operation

For best service you should incorporate an oiler, regulator, and inline filter, as shown in the

diagram above. Hoses, couplers, oilers, regulators, and filters are all available at Harbor

Freight Tools.

1. You will need to prepare a 1/4” air connector (sold separately) to connect to the air inlet

on the Nailer/Stapler First, wrap the 1/4” air connector (not included) with pipe thread

seal tape before connecting to a 3/8” ID Air Source Hose (not included). Connect the

Air Source Hose to the Air Plug (86).

Note:

If you are not using an automatic oiler system, before operation, add a few drops of

Pneumatic Tool Oil to the airline connection. Add a few drops more after each hour of

continual use.

2. Set the air pressure on your compressor to 60-100 PSI. Do not exceed the maximum

air pressure of 100 PSI.

3. Check the air connection for leaks.

Note: The amount of air pressure effects how deep the nails/staples will be driven.

It

is suggested that you experiment on scrap material.

4. Check the air connection for leaks and disconnect the Nailer/Stapler.

Nailer/

Stapler

1/4”-18 NPT