Page 9

For technical questions, please call 1-888-866-5797.

Item 61808

Sa

FE

ty

Op

E

ra

ti

O

n

Maint

E

nanc

E

S

E

tup

troubleshooting

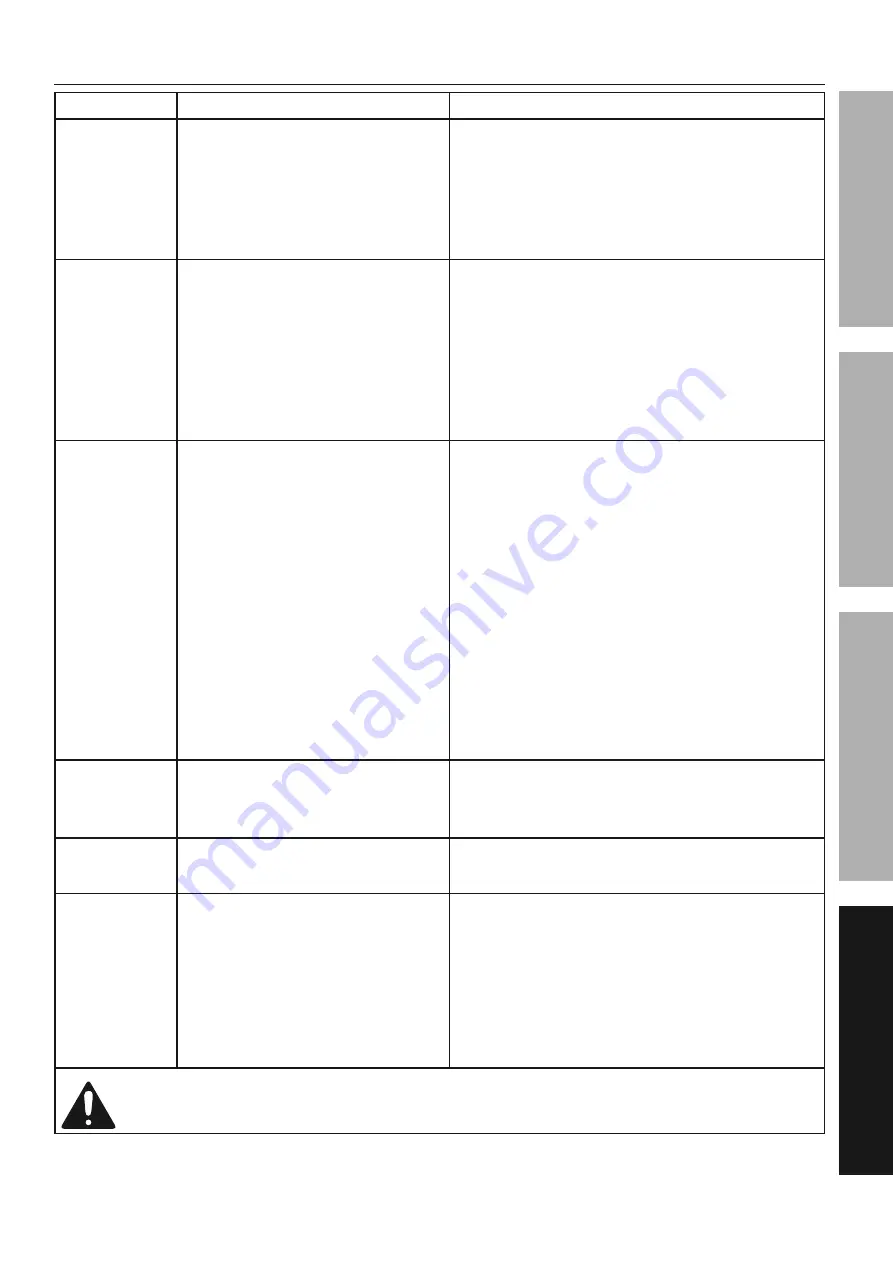

problem

possible causes

Likely Solutions

Machine does

not start or a

breaker trips.

1. Cord not connected.

2. No power at outlet.

3. Internal damage or wear.

4. Switch key removed.

1. Check that cord is plugged in.

2. Check power at outlet. If outlet is unpowered,

turn off tool and check circuit breaker.

If breaker is tripped, make sure circuit is right

capacity for tool and circuit has no other loads.

3. Have technician service tool.

4. Insert switch key.

Machine vibrates

or is noisy.

1. Motor or component is loose.

2. Motor mount loose/broken.

3. Machine is incorrectly

mounted or sits unevenly.

4. Motor fan is rubbing on fan cover.

5. Motor bearings are worn.

1. Inspect/replace stripped or damaged bolts/

nuts, and re-tighten with thread locking fluid.

2. Tighten/replace.

3. Tighten/replace mounting hardware;

chock casters if mobile.

4. Replace dented fan cover; replace

loose/ damaged fan.

5. Test by rotating shaft; rotational grinding/

loose shaft requires bearing replacement.

Dust collector

does not

adequately

collect dust

or chips; poor

performance.

1. Dust collection bag is full.

2. Restriction in duct line.

3. Dust collector is too far away,

or there are too many sharp

bends in the ducting.

4. Lumber is wet and dust is not

flowing through ducting smoothly.

5. Leaks in ducting or too

many open ports.

6. Ducting or machine dust ports

are incorrectly sized.

7. The machine dust collection

design is inadequate.

8. The dust collector is too small

for the task or machine.

1. Empty collection bag.

2. Remove restriction in the duct line. A

plumbing snake may be necessary.

3. Relocate the dust collector closer to the point of

suction, and rework ducting without sharp bends.

4. Process lumber with less than

20% moisture content.

5. Rework the ducting to eliminate all leaks.

Close dust ports for lines not being used.

6. Re-install correctly sized ducts and fittings.

7. Use a dust collection nozzle on a stand.

8. Use a larger dust collector.

Sawdust being

blown into the

air from the

dust collector.

1. Duct clamps or dust collection bag is

not properly clamped and secured.

2. Bag clamp is loose or damaged.

1. Re-secure ducts and dust collection bag,

making sure duct and bag clamps are tight

and completely over the ducts and bag.

2. Re-tighten bag clamp.

Tool operates

slowly.

Extension cord too long or

wire size too small.

Eliminate use of extension cord. If an extension cord

is needed, use one with the proper diameter for its

length and load. See

table a

on page 7.

Overheating.

1. Blocked motor housing vents.

2. Motor being strained by long or

small diameter extension cord.

3. Motor being strained by

over-full Collection Bag.

1. Wear ANSI-approved safety goggles and

NIOSH-approved dust mask/respirator while

blowing dust out of motor using compressed air.

2. Eliminate use of extension cord.

If an extension cord is needed, use one with

the proper diameter for its length and load.

See

table a

on page 7.

3. Empty Collection Bag. Do not

allow to fill past 3/4 full.

Follow all safety precautions whenever diagnosing or servicing the tool.

Disconnect power supply before service.