19

SA5 OPERATIONS MANUAL & PARTS LIST

(Rev. 2/2020)

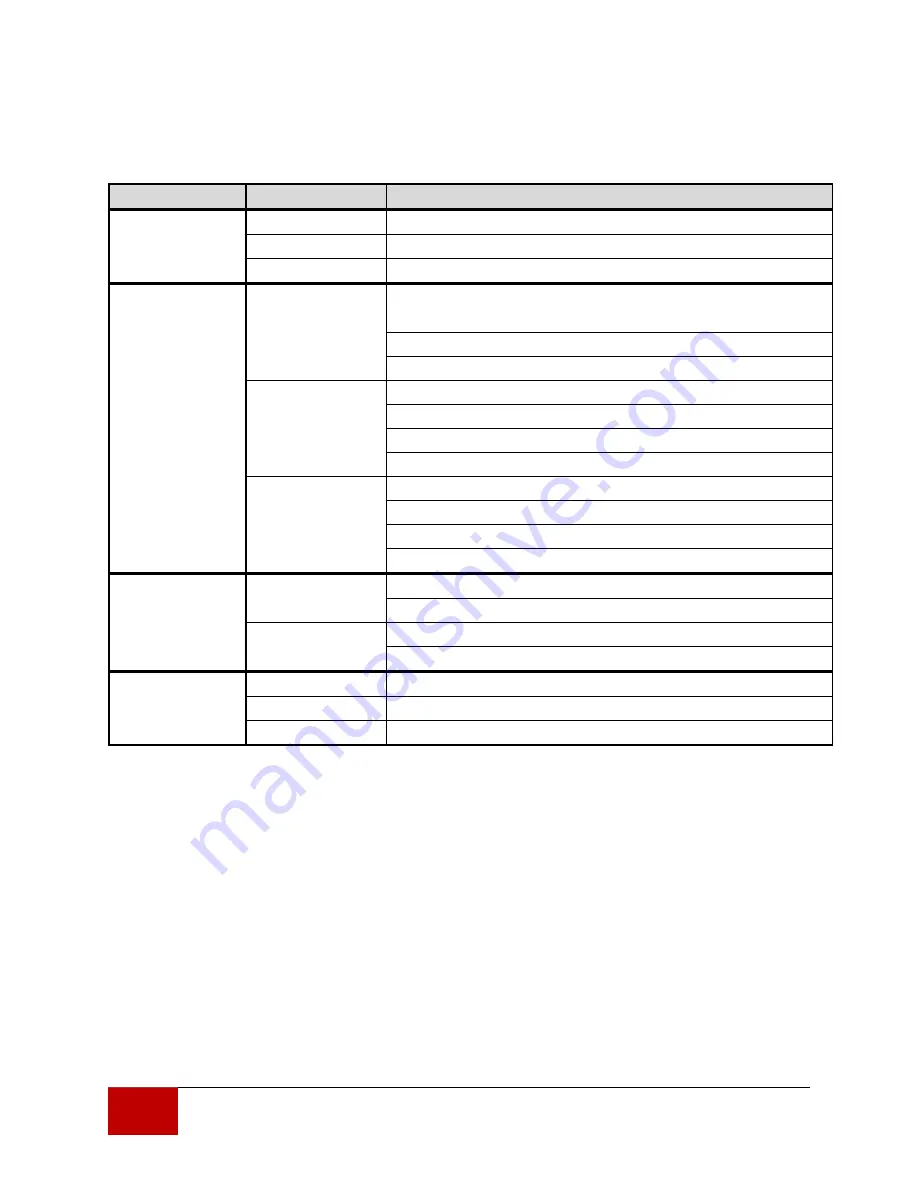

SECTION 6 – TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSES

CORRECTIVE ACTION

Air Supply

Make sure the unit is connected to an adequate air supply.

Hose Restrictions

Check air lines for kinks or other restrictions.

Blockage of Air Flow Check for debris that may have come through the air line.

Check hose for blockage.

Check gauge; replace if needed.

Tank is full; empty tank.

Make sure discharge valve is closed.

Air leakage; check gaskets and loose connections.

Check tank selector valve and air supply

Check for correct size air connections.

1/2 air-lines should hot exceed 40'.

Check for air flow out of the muffler.

Check tank selector valve and air supply for being completely open.

Check discharge hose for blockage.

Check for a build up of fines in tank bottom; clean if necessary.

Check that cap is on suction port.

Air leakage; check gaskets and loose connections.

Float Control

Check float control; clean or replace.

Excessive Foaming

Consult coolant supplier.

Tank Turbulence

Check to see if air is being sucked in the discharge.

Will not start

Check filter. If full, empty. If blinded, clean or go

to a coarser filter bag.

Vac/pres gauge reads

full vacuum but has no

suction.

Fluid coming out of

"Discharge" Tank-to -

Pump connection.

Vac/pres gauge reads

Low suction.

Loss of suction

Will not discharge

Vac/Pres gauge reads

"6" psi.

Vac/Pres gauge reads

"0" psi.

Vac/pres gauge reads

"0" vacuum.