TYPICAL RESERVOIR TANK

RECOMMENDED 6 TO 10 TIMES SYSTEM CAPACITY

1/4

5/16

3/8

1/2

5/8

3/4

1"

0.5

16

5

2

1

54

20

7

2

2

180

60

25

6

2

3

380

120

50

13

4

2

4

220

90

24

7

3

5

320

130

34

10

4

6

220

52

16

7

1

8

300

80

25

10

2

10

450

120

38

14

3

15

900

250

80

30

7

20

1600

400

121

50

12

25

650

200

76

19

30

250

96

24

40

410

162

42

50

600

235

62

60

370

93

*At a fixed flow rate with a given size hose, the pressure drop across a given hose length

will be directly proportional. A 50 ft. hose will exhibit one-half the pressure drop of a 100

ft. hose. Above values shown are valid at all pressure levels.

PRESSURE DROP IN PSI PER 100 FT OF HOSE

WITH TYPICAL WATER FLOW RATES

Hose Inside Diameters, Inches

Water*

Flow

Gal/Min

HOSE FRICTION LOSS

Water

GPM

1

2

3

5

8

10

15

25

40

60

80

100

Steel Pipe—Nominal Dia.

1/4 3/8 1/2 3/4

1 1

1

/

4

1

1

/

2

8.5 1.9

30 7.0 2.1

60 14 4.5 1.1

150 36

12 2.8

330 86

28 6.7 1.9

520 130

43 10 3.0

270

90 21 6.2 1.6

670 240 56

16 4.2 2.0

66

17 8.0

37

17

52

29

210 107

48

Brass Pipe—Nominal Dia.

1/4 3/8 1/2 3/4

1

1

1

/

4

1

1

/

2

6.0 1.6

20 5.6 1.8

40 11 3.6

100 28 9.0 2.2

220 62

21 5.2 1.6

320 90

30 7.8 2.4

190

62 16 5.0 1.5

470 150 40

12 3.8 1.7

39

11 5.0

23

11

40

19

61

28

Copper Tubing O.D. Type L

1/4 3/8 1/2 5/8 3/4 7/8

120 13 2.9 1.0

400 45

10 3.4 1.3

94

20 6.7 2.6

230

50 17 6.1 3.0

500 120 40

15 6.5

180 56

22

10

120

44

20

330 110

50

550 200

88

WATER LINE PRESSURE LOSS

PRESSURE DROP IN PSI PER 100 FEET

1/2

0.622

0.41

18.5

9.3

0.78

1.67

3.71

0.93

3.33

3/4

0.824

0.54

24.5

12.3

1.03

2.21

4.90

1.23

4.41

1

1.049

0.69

31.2

15.6

1.31

2.81

6.25

1.56

5.62

1

1

/

4

1.380

0.90

41.0

20.5

1.73

3.70

8.22

2.06

7.40

1

1

/

2

1.610

1.05

48.0

24.0

2.15

4.31

9.59

2.40

8.63

2

2.067

1.35

61.5

30.8

2.59

5.55

12.30

3.08

11.60

2

1

/

2

2.469

1.62

73.5

36.8

3.09

6.61

14.70

3.68

13.20

3

3.068

2.01

91.5

45.8

3.84

8.23

18.20

4.57

16.40

4

4.026

2.64

120.0

60.0

5.03

10.80

23.90

6.00

21.60

Nominal

Pipe

Size

Inches

Inside

Diameter

Inches

RESISTANCE OF VALVES AND FITTINGS

Gate

Valve

Globe

Valve

Angle

Valve

45˚

Elbow

90˚

Elbow

180˚

Close

Ret

Tee

Thru

Run

Arriving at a total line pressure loss, consideration should then be given to

pressure loss created by valves, fittings and elevation of lines.

If a sufficient number of valves and fittings are incorporated in the system to

materially affect the total line loss, add to the total line length, the equivalent

length of line of each valve or fitting.

Tee

Thru

Branch

Equivalent Length of Standard Pipe in Feet

Bypass Line

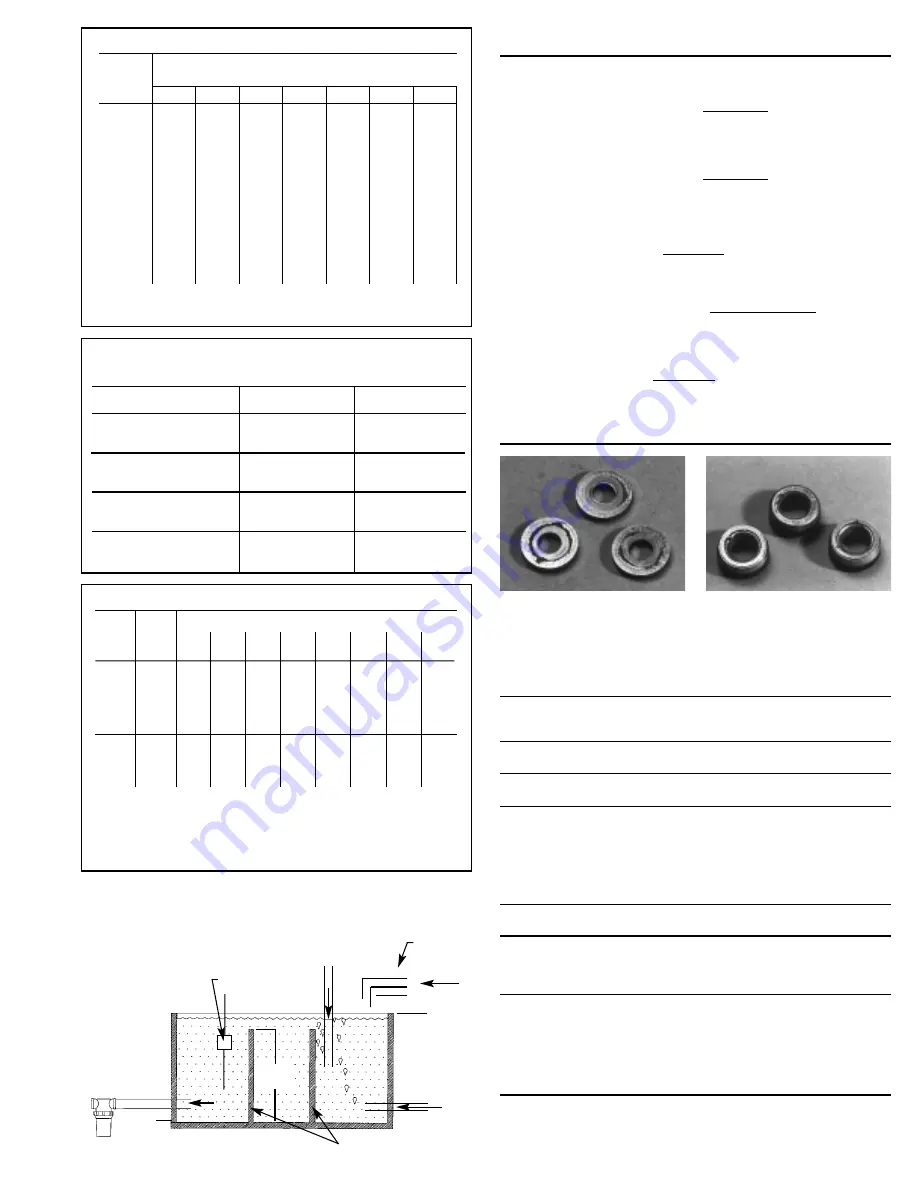

(from regulator or unloader)

Level Sensing

Device

Bypass Line

(from regulator or

unloader)

MIN. 4"

1.5 x D (Min.)

Minimum Two Baffles

Sealed at Bottom

Minimum

Liquid

Level

FILTER

MIN. 4"

Flexible Hose

to Pump

Supply Line

(Dia of pipe)

T

X

D

→

→

→

→

→

→

→

→

→

Q. How can I find the RPM needed to get specific GPM

(Gallons Per Minute) I want?

Rated RPM

A. Desired RPM = Desired GPM x

Rated GPM

Q. I have to run my pump at a certain RPM. How do I figure

the GPM I’ll get?

Rated GPM

A. Desired GPM = Desired RPM x

Rated RPM

Q. Is there a simple way to find the approximate horsepower

I’ll need to run the pump?

A. Electric Brake

GPM x PSI

(Standard 85%

Horsepower Required

=

1460

Mech. Efficiency)

Q. What size motor pulley should I use?

Pump RPM

A. Pump Pulley (Outer Diameter) x

Motor/Engine RPM

Q. How do I calculate the torque for my hydraulic drive

system?

GPM x PSI

A. Torque (ft. lbs.) = 3.6

RPM

( )

One or several of the conditions shown in the chart below may

contribute to cavitation in a system resulting in premature wear,

system downtime and unnecessary operating costs.

CONDITION

SOLUTION

Inadequate inlet

●

Increase line size to the inlet port or one size

line size

larger

Water hammering

●

Install C.A.T. Tube

liquid acceleration/

●

Move pump closer to liquid supply

deacceleration

Rigid Inlet Plumbing

●

Use flexible wire reinforced hose to absorb

pulsation and pressure spikes

Excessive Elbows in

●

Keep elbows to a minimum and less than 90°

Inlet Plumbing

Excessive Liquid

●

Use Thermo Valve in bypass line

Temperature

●

Do not exceed pump temperature specifications

●

Substitute closed loop with baffled holding tank

●

Adequately size tank for frequent or high

volume bypass

●

Pressure feed high temperature liquids

●

Properly ventilate cabinets and rooms

Air Leaks in Plumbing

●

Check all connections

●

Use PTFE thread tape or pipe thread sealant

Agitation in Supply

●

Size tank according to pump output —

Tank

Minimum 6-10 times system GPM

●

Baffle tank to purge air from liquid and

separate inlet from discharge

High Viscosity Liquids

●

Verify viscosity against pump specifications

before operation

●

Elevate liquid temperature enough to reduce

viscosity

●

Lower RPM of pump

●

Pressure feed pump

●

Increase inlet line size

Clogged Filters

●

Perform regular maintenance or use clean

filters to monitor build up

●

Use adequate mesh size for liquid and pump

specifications

Handy Formulas to Help You

(Consult

Engine Mfr.)

Avoid Cavitation Damage