– 10 –

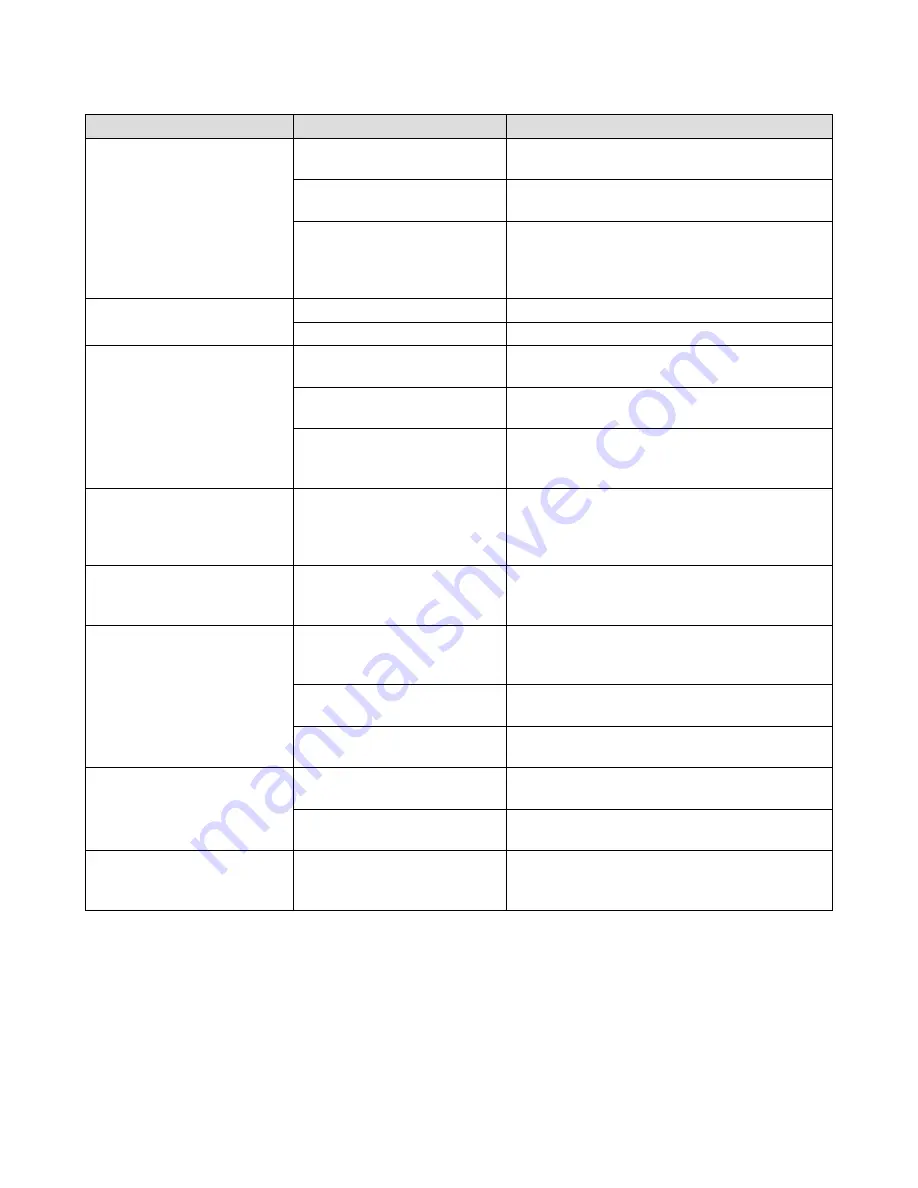

TROUBLESHOOTING

4444

Error Contents

Causes / Points to Check

Solutions

Can't turn the printer ON.

Is the power switch turned

ON?

Turn the power switch ON.

Is the connector on the power

adapter properly connected?

Connect the connector firmly.

Does the LED on the adapter

light up when connected to the

wall?

If the LED does not light up, check to see if the

power cable is connected properly. If the power

cable is connected properly, replace the AC

adaptor or the main PCB.

The ON LINE indicator

doesn't light up.

Is the ERROR Indicator ON? If it is, see "the ERROR Indicator is ON".

Press the ON LINE button

If the ON LINE indicator turns on, it's normal.

The ERROR Indicator is ON. Check if the printer is out of

paper.

If paper is out, replace with a new roll.

The cover doesn't open even if

you slide the cover open knob.

The Automatic Paper Cutter may be locked,

See "4.3 PAPER JAM".

The printer cover doesn't close

completely.

Open the cover by sliding the cover open knob,

and close it again by pushing at center of the

cover.

The ERROR indicator

doesn't light up while paper is

exhausted.

(The printer cover is close.)

The ON LINE indicator lights

up by using the ON LINE

button.

Check the sensor and the main PCB, and

replace them if necessary.

The ERROR indicator doesn’t

light up while the printer cover

is opened.

The ON LINE indicator is not

ON

Check the sensor and the main PCB, and

replace them if necessary.

Printing cannot be done

by the commands from the

HOST or printing garbled.

Check print capability by

running the self test.

If the printing cannot be performed, check the

printer head and/or the main PCB and replace

them if necessary.

Is the connector of interface

firmly connected with screws?

Set the connector firmly and tighten the screws.

Check the setting of DIP

switch.

Refer to "5. THE DIP SWITCHES". Set the

switches correctly, then power cycle the printer.

The drawer kick doesn't work. Is the drawer kick connected

properly?

Re-plug in the cable. You should hear or feel a

click if the proper connection is made.

Is Y-cable connected in

reverse order?

Check the Y-cable and verify it is connected in

the correct order.

The ERROR indicator and ON

LINE indicator flash on and off

alternately.

Check the setting of DIP

Switch.

Refer to "5. THE DIP SWITCHES". Turn the

printer off, make any necessary changes, then

turn the printer on.