IOM-POSR-2

14

7. Slowly pressurize the inlet of the main valve

(MV) and pilot valve (PV) to 100 psig (6.9 Barg).

NOTE:

If the pilot valve (PV) has any other

range spring (15) above 5–15 psig (.34–1.03

Barg), the test pressure can be raised to 200

psig (13.8 Barg)

.

8. Using a solution of leak detection fluid and

water, apply a liberal amount of the solution to

cover each external joint, including the thread ed

fittings (20), tub ing (21) and the interconnecting

pipe nipple (19) threaded con nec tions. Wait

a minimum of five min utes to allow sufficient

time for a leak to form bub bles. Repeat this

procedure with a second five minute wait.

SECTION VIII

9. Identify and mark any observed leakage.

Dis as sem ble down to the point of leakage

and determine the cause of the leak. Repair

and reassemble per instructions in Section

VI. Retest per Section VII.

10. Shut off pressure to inlet connection of

main valve (MV) and remove all leak testing

equip ment. Reset the adjusting screw (19)

back to its normal setpoint by rotating the

screw (19) CCW (viewed from above) the

same num ber of revolutions recorded in Ar ti cle

6. pre vi ous, this subsection.

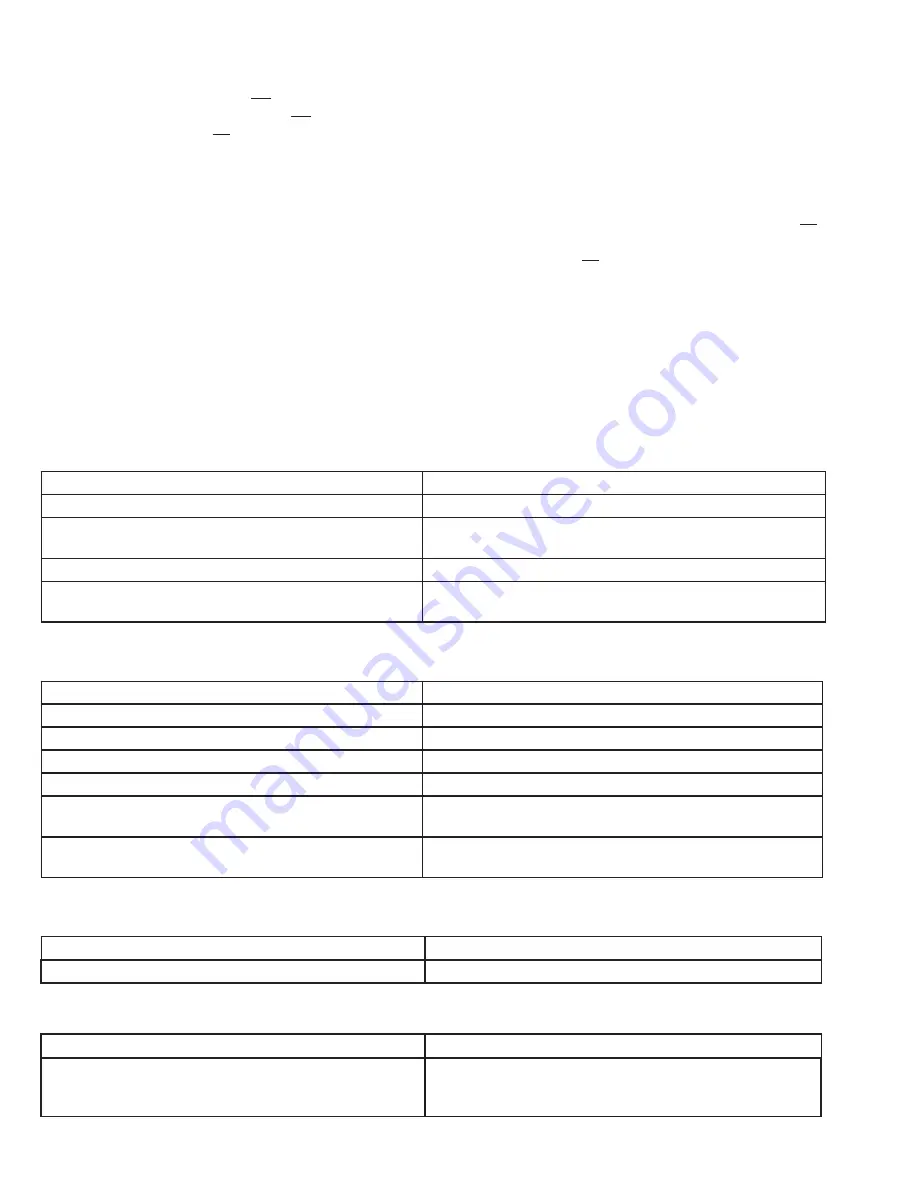

VIII. TROUBLE SHOOTING GUIDE

1. Erratic or Noisy Operation.

Possible Cause

Remedy

a.

Wet steam or condensate at the inlet.

a.

Install a steam trap on the inlet side of the regulator.

b.

Clogged pilot valve screen.

b.

Clean or replace. Blowdown inlet drip leg. Install up-

stream strainer, if severe.

c.

Regulator oversized for flow conditions.

c.

Install correct size.

d.

Insufficiently sloped line.

d.

Move tap from top of pipe to side; or, increase sensing

tube to 3/8" OD.

2. Regulator won't maintain downstream set pressure.

Possible Cause

Remedy

a.

Valve undersized.

a.

Resize based on actual service conditions.

b.

Incorrect range spring.

b.

Replace range spring.

c.

Failed bellows.

c.

Replace bellows assembly.

d.

Failed piston seal ring.

d.

Replace seal ring.

e.

Pressure drop less than required 15 or 20 psid

(1–1.4 Bard).

e.

Contact your Cashco Representative.

f.

Insufficiently sloped line.

f.

Move tap from top of pipe to side; or, increase sensing

tube to 3/8" OD.

Possible Cause

Remedy

a.

Defective diaphragm.

a.

Replace diaphragm.

3. Leakage through the pilot spring chamber vent hole.

4. Excessive pressure downstream.

Possible Cause

Remedy

a.

Main valve or pilot plug not closing.

a.

Inspect the seating of the main valve and then the

pilot plug seating. Clean or replace. Check seat

gaskets; replace.