RS Series – Multi-Stage, Ring Section Pumps

January 2001

19

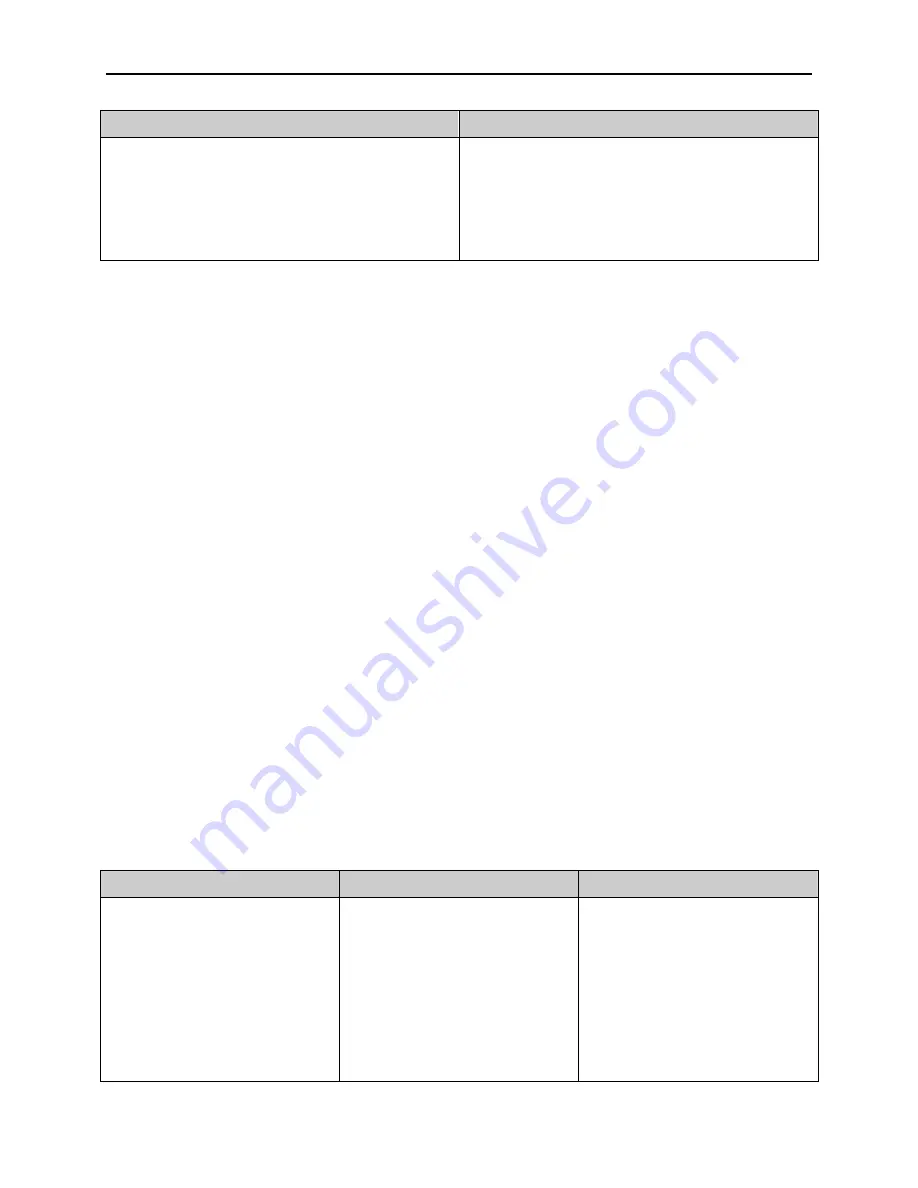

Table 10. Recommended Torque Values

Fastener Size

Torque (foot pounds)

1/4-20 UNC

5

5/16-18 UNC

10

3/8-16 UNC

15

1/2-13 UNC

30

7/8-14 UNF

315

1-12 UNF

446

D. Disassembly and Assembly

Preparations

NOTE

Refer to Section V, paragraph H for oil

lubrication and water cooling

disassembly and assembly procedures.

During disassembly, match mark parts so they

can be replaced in their original position. All

parts should be thoroughly cleaned or replaced

with new, if necessary. Sealing faces should be

perfectly clean. Carver Pump Company

recommends that all o-rings and shims are only

used once.

NOTE

To avoid damage to o-rings, check to

make sure all parts are free of sharp

edges or burrs.

Close suction and/or discharge valves. The

pump cases should be cooled down to ambient

temperature. Cases must be empty and not

under pressure.

After prolonged operation, components may not

be easily removed from shaft. In such instances,

rust solvent may be used and suitable extracting

tools applied wherever possible. Do NOT use

force under any circumstances. Refer to Table

11, Recommended Tools, for proper tooling

during disassembly and assembly.

Refer to appropriate sectional drawing, for

location of parts followed by an item number.

Assemble the pump in accordance with

accepted rules of engineering practice. Coat

individual components with a suitable lubricant

before assembling. Assembly of unit should be

performed on a flat surface.

While assembling the pumping unit, Carver

Pump Company recommends that the following

parts be replaced with new:

•

O-rings

•

Shims

•

Bearings

•

Grease seals

•

Mechanical seals

If new impellers or new shaft protecting sleeves

are fitted, impellers must be axially aligned with

respect to diffusers. Refer to paragraph F of this

section for procedures regarding axial impeller

alignment.

Table 11. Recommended Tools

Tools

Materials

Testing Equipment

Spanner wrench

Grease (Rykon) or oil

Coupling alignment gauges

Rawhide or wood mallet

Wooden wedge

Allen wrench set

Socket, open, & box wrench set

Vice grips

“C” clamp

Summary of Contents for RS A

Page 1: ...I 280...

Page 2: ......

Page 4: ...NOTES ON INSPECTION AND REPAIRS INSPECTION DATE REPAIR TIME REPAIRS COST REMARKS...

Page 32: ...26 BLANK...

Page 38: ...32 BLANK...

Page 40: ...34 BLANK...

Page 44: ...RS Series Multi Stage Ring Section Pumps January 2001 38 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 46: ...40 BLANK...

Page 48: ...42 BLANK...

Page 54: ...48 BLANK...

Page 56: ...50 BLANK...

Page 62: ...56 BLANK...

Page 64: ...58 BLANK...

Page 66: ......

Page 67: ...I 280 REV 04 March 2002...