25

Step 4 — Fill the Chilled Water Loop

WATER SYSTEM CLEANING — Proper water system

cleaning is of vital importance. Excessive particulates in the

water system can cause excessive pump seal wear, reduce or

stop flow, and cause damage of other components. Water

quality should be maintained within the limits indicated in

Table 3. Failure to maintain proper water quality may result in

heat exchanger failure.

1. Install a temporary bypass around the chiller to avoid cir-

culating dirty water and particulates into the pump pack-

age and chiller during the flush. Use a temporary circulat-

ing pump during the cleaning process. Also, be sure that

there is capability to fully drain the system after cleaning.

(See Fig 22.)

2. Be sure to use a cleaning agent that is compatible with all

system materials. Be especially careful if the system

contains any galvanized or aluminum components. Both

detergent-dispersant and alkaline-dispersant cleaning

agents are available.

3. It is a good idea to fill the system through a water meter.

This provides a reference point for the future for loop

volume readings, but it also establishes the correct

quantity of cleaner needed in order to get the required

concentration.

4. Use a feeder/transfer pump to mix the solution and fill the

system. Circulate the cleaning system for the length of

time recommended by the cleaning agent manufacturer.

a. After cleaning, drain the cleaning fluid and flush the

system with fresh water.

b. A slight amount of cleaning residue in the system can

help keep the desired, slightly alkaline, water pH of 8

to 9. Avoid a pH greater than 10, since this will

adversely affect pump seal components.

c. A side stream filter is recommended (see Fig. 23)

during the cleaning process. Filter side flow rate

should be enough to filter the entire water volume

every 3 to 4 hours. Change filters as often as neces-

sary during the cleaning process.

d. Remove temporary bypass when cleaning is

complete.

Table 3 — Water Quality Characteristics

and Limitations

*

Sulfides in the water quickly oxidize when exposed to air, requiring that

no agitation occur as the sample is taken. Unless tested immediately

at the site, the sample will require sta

b

ilization with a few drops of one

Molar zinc acetate solution, allowing accurate sulfide determination up

to 24 hours after sampling. A low pH and high alkalinity cause system

pro

b

lems, even when

b

oth values are within the ranges shown. The

term pH refers to the acidity,

b

asicity, or neutrality of the water supply.

Below 7.0, the water is considered to

b

e acidic. A

b

ove 7.0, water is

considered to

b

e

b

asic. Neutral water contains a pH of 7.0.

†Dissolved car

b

on dioxide can either

b

e calculated from the pH and

total alkalinity values, shown

b

elow, or measured on the site using a

test kit. Dissolved Car

b

on Dioxide, PPM = TA x 2

[(6.3-pH)/0.3]

where TA

= Total Alkalinity, PPM as CaCO

3

.

A 40-mesh strainer with a blow-down valve is standard on

all 30RAP units, both with and without hydronic packages.

The blow-down valve allows removal of particulates caught in

the strainer without complete removal of the screen. A female

NPT connection is provided on the valve, allowing hose con-

nection for drainage outside the unit.

Carrier’s

Comfort

Link controls provided have a built-in

feature to remind building owners or operators to clean the

strainer by discharging the blow-down valve at a pre-set time

interval. Properly installed and cleaned systems will rarely

need the strainer cleaned after the initial fill. This time interval

is user-configurable.

FILLING THE SYSTEM — The initial fill of the chilled

water system must accomplish three purposes:

1. The entire piping system must be filled with water.

2. The pressure at the top of the system must be high enough

to vent air from the system (usually 4 psig [28 kPa] is ad-

equate for most vents).

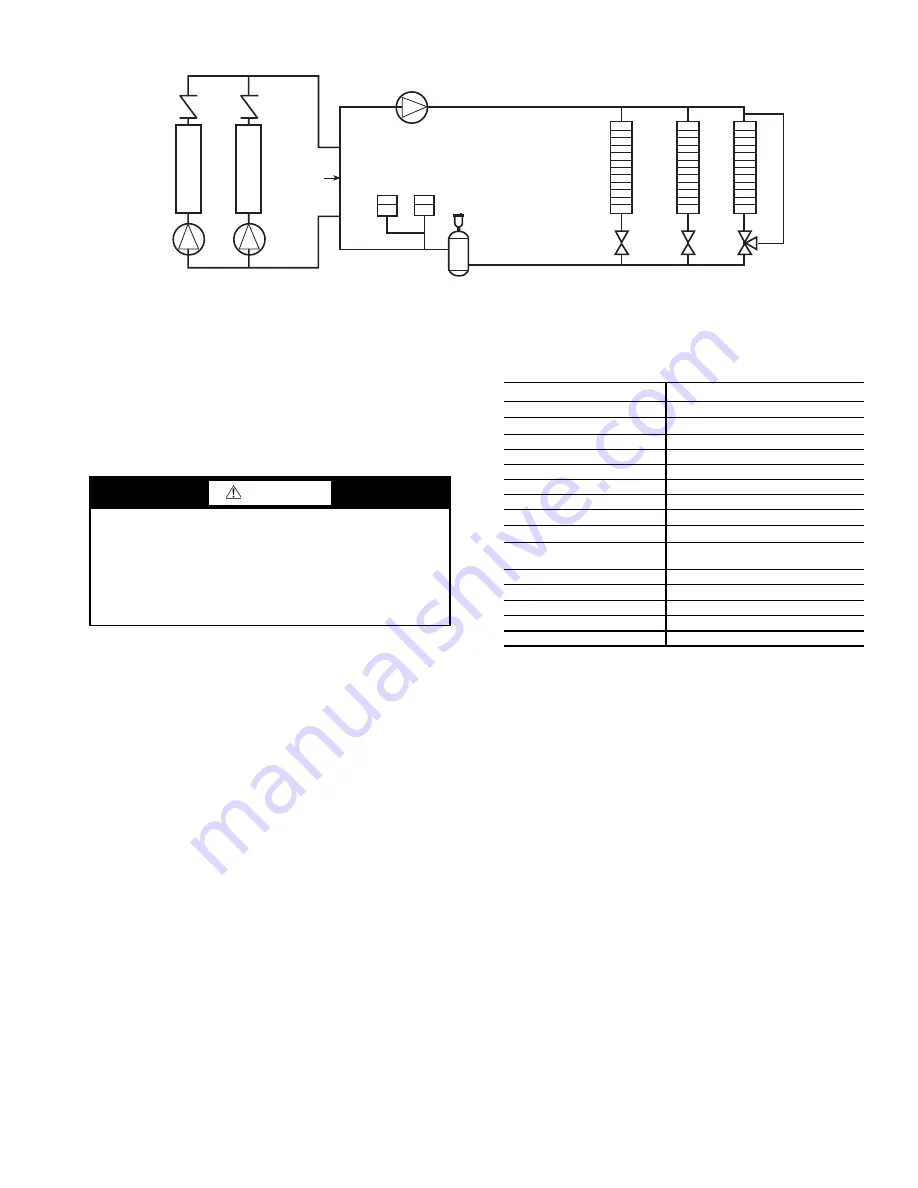

Di

s

trib

u

tion P

u

mp

Exp

a

n

s

ion

T

a

nk(

s

)

Air

S

ep

a

r

a

tor

with Vent

Deco

u

pler

Chiller 1

Chiller 2

Zone 1

Zone 2

Zone

3

NOTE: Expansion tanks in the 30RAP hydronic kits must

b

e disconnected for chillers placed parallel in the primary water loop.

Fig. 21 — Typical Air Separator and Expansion Tank Location on Primary-Secondary Systems

CAUTION

Failure to properly clean all piping and components of the

chilled water system before unit start-up may result in

plugging of the heat exchanger, which can lead to poor per-

formance, nuisance alarms and damage from freezing.

Freezing damage caused by an improperly cleaned system

represents abuse and may impair or otherwise negatively

affect the Carrier product warranty.

WATER CHARACTERISTIC

QUALITY LIMITATION

Alkalinity (HCO

3

-

)

70 – 300 ppm

Sulfate (SO

4

2-

)

Less than 70 ppm

HCO

3

-

/SO

4

2-

Greater than 1.0

Electrical Conductivity

10 – 500

S/cm

pH

7.5 – 9.0

Ammonia (NH

3

)

Less than 2 ppm

Chorides (Cl

-

)

Less than 300 ppm

Free chlorine (Cl

2

)

Less than 1 ppm

Hydrogen Sulfide (H

2

S)*

Less than 0.05 ppm

Free (aggressive) Carbon

Dioxide (CO

2

)†

Less than 5 ppm

Total Hardness (°dH)

4.0 –

8

.5

Nitrate (NO

3

)

Less than 100 ppm

Iron (Fe)

Less than 0.2 ppm

Aluminum (Al)

Less than 0.2 ppm

Manganese (Mn)

Less than 0.1 ppm

Summary of Contents for AQUASNAP 30RAP010-150

Page 12: ...12 Fig 9A Unit Rigging Label Detail 010 060 Sizes a30 4916 ...

Page 14: ...14 a30 5733 Fig 10 Dimensions 30RAP010 and 015 Units ...

Page 15: ...15 a30 5734 Fig 11 Dimensions 30RAP018 030 Units ...

Page 16: ...16 a30 5735 Fig 12 Dimensions 30RAP035 060 Units ...

Page 17: ...17 Fig 13 Dimensions 30RAP070 090 Units a30 5731 ...

Page 18: ...18 Fig 14 Dimensions 30RAP100 115 Units a30 5730 ...

Page 19: ...19 a30 5732 Fig 15 Dimensions 30RAP130 150 Units ...

Page 54: ...54 Fig 33 Typical Main Power and Control Connections a30 5514 ...

Page 71: ......