(3.) Turn high-fire adjusting screw (5/64-in. hex Allen

wrench) counterclockwise (out) to decrease input rate

or clockwise (in) to increase rate. When adjusting

input rate, DO NOT set manifold pressure less than

3.2-in. wc or more than 3.8-in. wc for natural gas. If

manifold pressure is outside this range, change main

burner orifices.

(4.) Remove R-to-W2 jumper on control to place furnace

in low-gas-heat operation for low-fire adjustment.

(5.) Turn low-fire adjusting screw (5/64-in. hex Allen

wrench) counterclockwise (out) to decrease input rate

or clockwise (in) to increase rate. When adjusting

input rate, DO NOT set manifold pressure less than

1.3-in wc or more than 1.7-in. wc for natural gas. If

manifold pressure is outside this range, change main

burner orifices.

NOTE:

If orifices are changed, both high-fire and low-fire input

rates must be readjusted with manifold pressures within ranges

specified in items (3). and (5).

NOTE:

If orifice hole appears damaged or is suspected to have

been redrilled, check the orifice size with a numbered drill bit of

the correct size. Never use a redrilled orifice. A burr-free and

squarely aligned orifice hole is essential for proper flame charac-

teristics.

(6.) Remove jumper on R-W/W1 after low-fire adjust-

ments.

(7.) When correct input is obtained, replace gas control

regulator adjustment caps. Main burner flame should

be clear blue, almost transparent. (See Fig. 17.)

2. Set temperature rise.

Place SW-2 in the ON position. Jumper R to W/W1 and W2

to check high-gas-heat temperature rise. To check low-gas-

heat temperature rise, remove jumper to W2. Determine air

temperature rise for both high and low fire using the following

steps. DO NOT exceed the temperature rise ranges specified

on the unit rating plate for high and low fire.

a. Place duct thermometers in return and supply ducts as near

furnace as possible. Be sure thermometers do not see heat

exchangers so that radiant heat will not affect thermometer

readings. This is particularly important with straight-run

ducts.

b. When thermometer readings stabilize, subtract return-air

temperature from supply-air temperature to determine tem-

perature rise.

NOTE:

If the temperature rise is outside this range, first check:

(1.) Gas input for low- and high-fire operation.

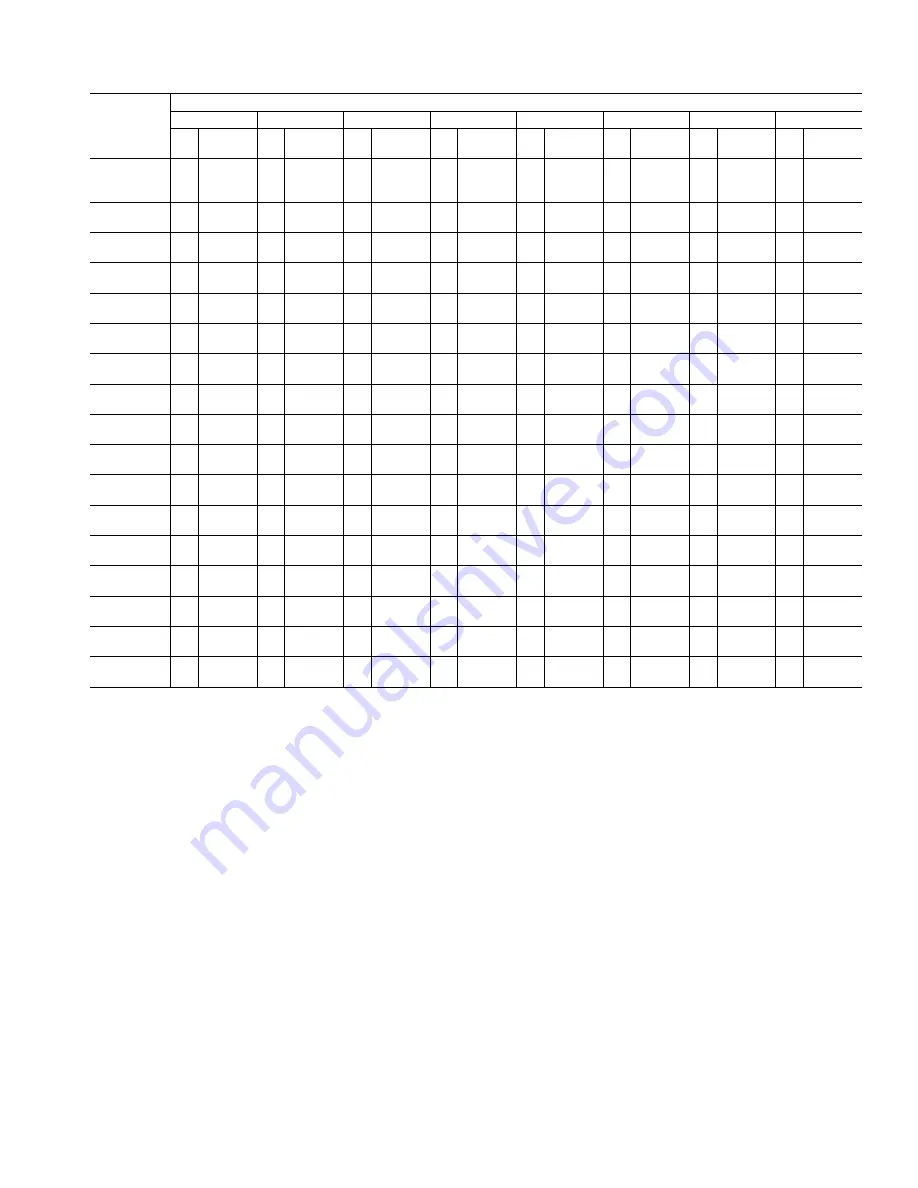

Table 8—Model 58TMA Orifice Size and Manifold Pressure for Correct Input Rate

(Tabulated Data Based on Altitude Up to 2000 ft and 21,000 Btuh High Heat/13,500 Btuh Low Heat Per Burner)*

GAS

HEAT

VALUE

(BTU/CU FT)

SPECIFIC GRAVITY OF NATURAL GAS

0.58

0.60

0.62

0.64

0.66

0.68

0.70

0.72

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

Orf

No.

Heat

High/Low

860

—

—

42

3.5/1.4

42

3.2/1.3

3.6/1.5

41

42

3.3/1.4

3.7/1.5

40

41

42

3.2/1.3

3.4/1.4

3.8/1.6

40

41

3.3/1.3

3.5/1.5

40

41

3.3/1.4

3.6/1.5

39

40

41

3.2/1.3

3.4/1.4

3.7/1.5

875

42

3.2/1.3

42

3.3/1.4

42

3.4/14

41

42

3.2/1.3

3.6/1.5

41

42

33.3/1.4

3.7/1.5

41

42

3.4/1.4

3.8/1.6

40

41

3.2/1.3

3.5/1.4

40

41

3.3/1.4

3.6/1.5

890

43

3.8/1.6

42

3.2/1.3

43

3.3/1.4

42

3.4/1.5

41

42

3.2/1.3

3.5/1.5

41

42

3.3/1.4

3.7/1.5

41

42

3.4/1.4

3.8/1.6

40

41

3.2/1.3

3.5/1.4

905

43

3.7/1.5

43

3.8/1.6

43

3.2/1.3

42

3.3/1.4

42

3.4/1.4

41

42

3.2/1.3

3.5/1.4

41

42

3.3/1.4

3.6/1.5

41

42

3.4/1.4

3.7/1.5

920

43

3.6/1.5

43

3.7/1.5

43

3.8/1.6

42

3.2/1.3

42

3.3/1.4

42

3.4/1.4

41

42

3.2/1.3

3.5/1.5

41

42

3.3/1.3

3.6/1.5

935

43

3.4/1.4

43

3.6/1.5

43

3.7/1.5

43

3.8/1.6

42

3.2/1.3

42

3.3/1.3

42

3.4/1.4

41

42

3.2/1.3

3.5/1.4

950

43

44

3.3/1.4

3.8/1.6

43

3.5/1.4

43

44

3.6/1.5

43

3.7/1.5

43

3.8/1.6

42

3.2/1.3

42

3.3/1.4

42

3.4/1.4

965

43

44

3.2/1.3

3.7/1.5

43

44

3.3/1.4

3.8/1.6

43

44

3.5/1.4

43

3.6/1.5

43

3.7/1.5

43

3.8/1.5

42

3.2/1.3

42

3.3/1.4

980

44

3.6/1.3

43

44

3.2/1.3

3.7/1.5

43

44

3.4/1.4

3.8/1.6

43

3.5/1.4

43

3.6/1.5

43

3.7/1.5

43

3.8/1.6

42

3.2/1.3

995

44

3.5/1.4

44

3.6/1.5

44

3.3/1.3

3.7/1.5

43

44

3.4/1.4

3.8/1.6

43

3.5/1.4

43

3.6/1.4

43

3.7/1.5

43

3.8/1.6

1010

44

3.4/1.4

44

3.5/1.4

44

3.2/1.3

3.6/1.5

43

44

3.3/1.3

3.7/1.5

43

44

3.4/1.4

3.8/1.6

43

3.5/1.4

43

3.6/1.5

43

3.7/1.5

1025

44

3.3/1.4

44

3.4/1.4

44

3.5/1.4

43

44

3.2/1.3

3.6/1.5

43

44

3.3/1.3

3.7/1.5

43

44

3.4/1.4

3.8/1.5

43

3.5/1.4

43

3.6/1.5

1040

44

3.1/1.3

44

3.3/1.4

44

3.4/1.4

44

3.5/1.4

43

44

3.2/1.3

3.6/1.5

43

44

3.3/1.3

3.7/1.5

43

44

3.4/1.4

3.8/1.6

43

3.5/1.4

1055

45

3.8/1.6

44

3.2/1.3

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

43

44

3.2/1.3

3.6/1.5

43

44

3.3/1.4

3.4/1.5

43

44

3.4/1.4

3.8/1.6

1070

45

46

3.7/1.5

3.8/1.6

45

3.8/1.6

44

3.2/1.3

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

43

44

3.2/1.3

3.6/1.5

43

44

3.3/1.4

3.7/1.5

1085

45

46

3.6/1.5

3.7/1.5

45

3.7/1.5

45

3.8/1.6

44

3.2/1.3

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

43

44

3.2/1.3

3.6/1.5

1100

45

46

3.5/1.4

3.6/1.5

45

46

3.6/1.8

3.8/1.6

45

3.7/1.5

45

3.8/1.6

44

3.2/1.3

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

* For size 060125 only, input is 20,500 for high fire. Deduct 0.1-in. wc from manifold pressure shown in table. Change orifice size if manifold pressure falls below 3.2-in.

wc.

15