Step 4—Outdoor Fan

Keep the condenser fan free from all obstructions to ensure

proper cooling operation. Never place articles on top of the

unit. Damage to unit may result.

1. Remove 6 screws holding outdoor grille and motor to top

cover.

2. Turn motor/grille assembly upside down on top cover to

expose fan blade.

3. Inspect the fan blades for cracks or bends.

4. If fan needs to be removed, loosen setscrew and slide fan off

motor shaft.

5. When replacing fan blade, position blade so that the hub is 1/8

in. away from the motor end (1/8 in. of motor shaft will be

visible). (See Fig. 23)

6. Ensure that setscrew engages the flat area on the motor shaft

when tightening.

7. Replace grille.

Step 5—Electrical Controls and Wiring

Inspect and check the electrical controls and wiring annually. Be

sure to turn off the electrical power to the unit.

Remove access panel to locate all the electrical controls and

wiring. Check all electrical connections for tightness. Tighten all

screw connections. If any smoky or burned connections are

noticed, disassemble the connection, clean all the parts, restrip the

wire end and reassemble the connection properly and securely.

After inspecting the electrical controls and wiring, replace all the

panels. Start the unit, and observe at least one complete cooling

cycle to ensure proper operation. If discrepancies are observed in

operating cycle, or if a suspected malfunction has occurred, check

each electrical component with the proper electrical instrumenta-

tion. Refer to the unit wiring label when making these checkouts.

Step 6—Refrigerant Circuit

Inspect all refrigerant tubing connections and the unit base for oil

accumulation annually. Detecting oil generally indicates a refrig-

erant leak.

If oil is detected or if low performance is suspected, leak-test all

refrigerant tubing using an electronic leak detector, or liquid-soap

solution. If a refrigerant leak is detected, refer to Check for

Refrigerant Leaks section.

If no refrigerant leaks are found and low performance is suspected,

refer to Checking and Adjusting Refrigerant Charge section.

Step 7—Indoor Airflow

The heating and/or cooling airflow does not require checking

unless improper performance is suspected. If a problem exists, be

sure that all supply- and return-air grilles are open and free from

obstructions, and that the air filter is clean. When necessary, refer

to Indoor Airflow and Airflow Adjustments section to check the

system airflow.

Step 8—Metering Devices–TXV & Accurater Piston

This unit uses 2 types of metering devices. The outdoor metering

device is a fixed orifice and is contained in the brass hex-body in

the liquid line feeding the outdoor coils. The indoor metering

device is a TXV type device.

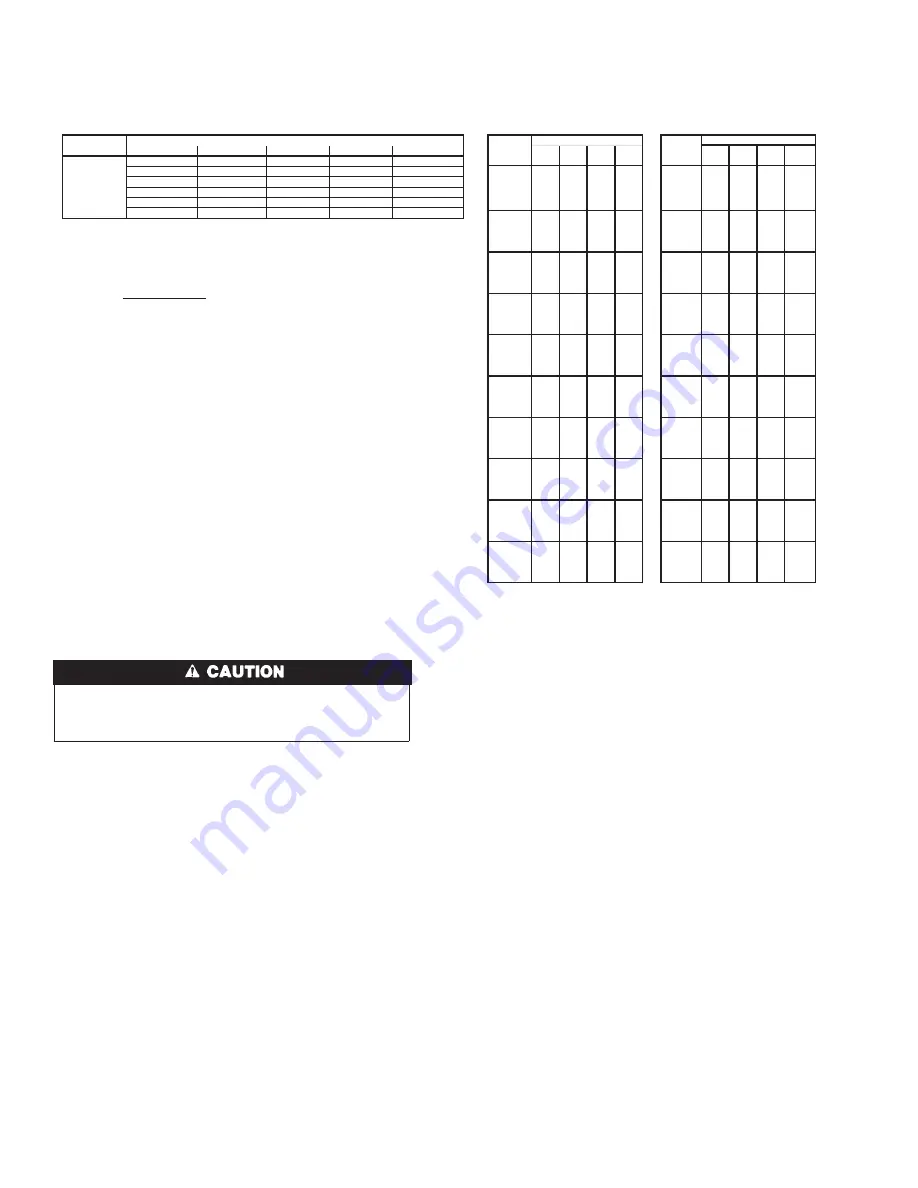

Fig. 27—Cooling Charging Table-Subcooling

C03027

(psig)

5

10

15

20

(kPa)

3

6

8

11

189

61

56

51

46

1303

13

13

11

8

203

66

61

56

51

1399

13

16

13

10

10.3 (5.7)

9.8 (5.4)

9.4 (5.2)

9 (5)

8.6 (4.7)

210

68

63

58

53

1448

13

17

14

11

NA

NA

NA

NA

NA

217

70

65

60

55

1496

13

18

15

13

17.6 (9.8)

16.8 (9.3)

16.5 (9.2)

15.4 (8.6)

14.3 (7.9)

224

72

67

62

57

1544

13

19

16

14

NA

NA

NA

NA

NA

231

74

69

64

59

1593

13

20

18

15

17.5 (9.7)

16.9 (9.4)

16.6 (9.2)

15.7 (8.7)

14.8 (8.2)

238

76

71

66

61

1641

13

21

19

16

13.7 (7.6)

13 (7.2)

13 (7.2)

14.5 (8.1)

11.5 (6.4)

245

77

72

67

62

1689

13

22

20

17

252

79

74

69

64

1737

13

23

21

18

260

81

76

71

66

1792

13

25

22

19

268

83

78

73

68

1848

13

26

23

20

276

85

80

75

70

1903

13

27

24

21

284

87

82

77

72

1958

13

28

25

22

292

89

84

79

74

2013

13

29

26

23

300

91

86

81

76

2068

13

30

27

24

309

93

88

83

78

2130

13

31

28

26

318

95

90

85

80

2192

13

32

29

27

327

97

92

87

82

2254

13

33

31

28

336

99

94

89

84

2316

13

34

32

29

345

101

96

91

86

2378

13

35

33

30

354

103

98

93

88

2440

13

36

34

31

364

105

100

95

90

2509

13

38

35

32

374

107

102

97

92

2578

13

39

36

33

384

108

103

98

93

2647

13

40

37

34

394

110

105

100

95

2716

13

41

38

35

404

112

107

102

97

2785

13

42

39

36

414

114

109

104

99

2854

13

43

40

37

424

116

111

106

101

2923

13

44

41

38

434

118

113

108

103

2992

13

45

42

39

444

119

114

109

104

3061

13

46

43

40

454

121

116

111

106

3130

13

47

44

41

464

123

118

113

108

3199

13

48

45

42

474

124

119

114

109

3268

13

48

46

43

484

126

121

116

111

3337

13

49

47

44

494

127

122

117

112

3406

13

50

47

45

504

129

124

119

114

3475

13

51

48

46

514

131

126

121

116

3544

13

52

49

46

524

132

127

122

117

3612

13

53

50

47

534

134

129

124

119

3681

13

54

51

48

Required Liquid Line Temperature for

Required Subcooling Deg F (Deg C)

Model Size

a Specific Subcooling (R-410A)

Charging Procedure

7- Read across from the Pressure reading to obtain the Liquid line temperature for a

required Subcooling

6- Find the Pressure Value in the table corresponding to the the measured Pressure of

the Compressor Discharge line.

5- Interpolate if the Outdoor ambient temperature lies in between the table values.

Extrapolate if the temperature lies beyond the table range.

1- Measure Discharge line pressure by attaching a gauge to the service port.

2- Measure the Liquid line temperature by attaching a temperature sensing device to it.

3- Insulate the temperature sensing device so that the Outdoor Ambient doesn’t affect

the reading.

4- Refer to the required Subcooling in the table based on the model size and the

Outdoor Ambient temperature.

8- Add Charge if the measured temperature is higher than the table value.

9- Add Charge using the service connection on the Suction line of the Compressor.

024

030

036

042

048

060

Outdoor Ambient Temperature

75 (24) 82 (28) 85 (29) 95 (35) 105 (41)

Pressure

Pressure

196

1351

Required Subcooling (Deg F)

Required Subcooling (Deg C)

63

58

53

48

13

15

12

9

24