19

LEAK TESTING

After securing the connections, test the system for any leaks.

Always test hydronic systems with water as some components are

not designed to be inert gas pressurized.

Field pressure testing for leaks should not exceed 300 psi for

hydronic coil and valve package components. Consult factory if

higher limits are required.

REFRIGERANT COIL TESTING

Test refrigerant systems with dry nitrogen rather than air to pre

-

vent the introduction of moisture into the system. In the event that

leaking or defective components are discovered, notify the Sales

Representative BEFORE any repairs are attempted. All leaks must

be repaired before proceeding with the installation. In DX

systems, adequate freeze protection should be field-installed. Ex

-

ternal equalizer should be installed by others.

PIPING INSULATION

After system integrity has been established, insulate the piping in

accordance with the project specifications. This is the responsibili

-

ty of the installing or insulation contractor.

CONDENSATE DRAIN

Any fan coil unit with a drain pan is recommended to be equipped

with a drain trap to provide condensate drainage and prevent prop

-

erty damage.

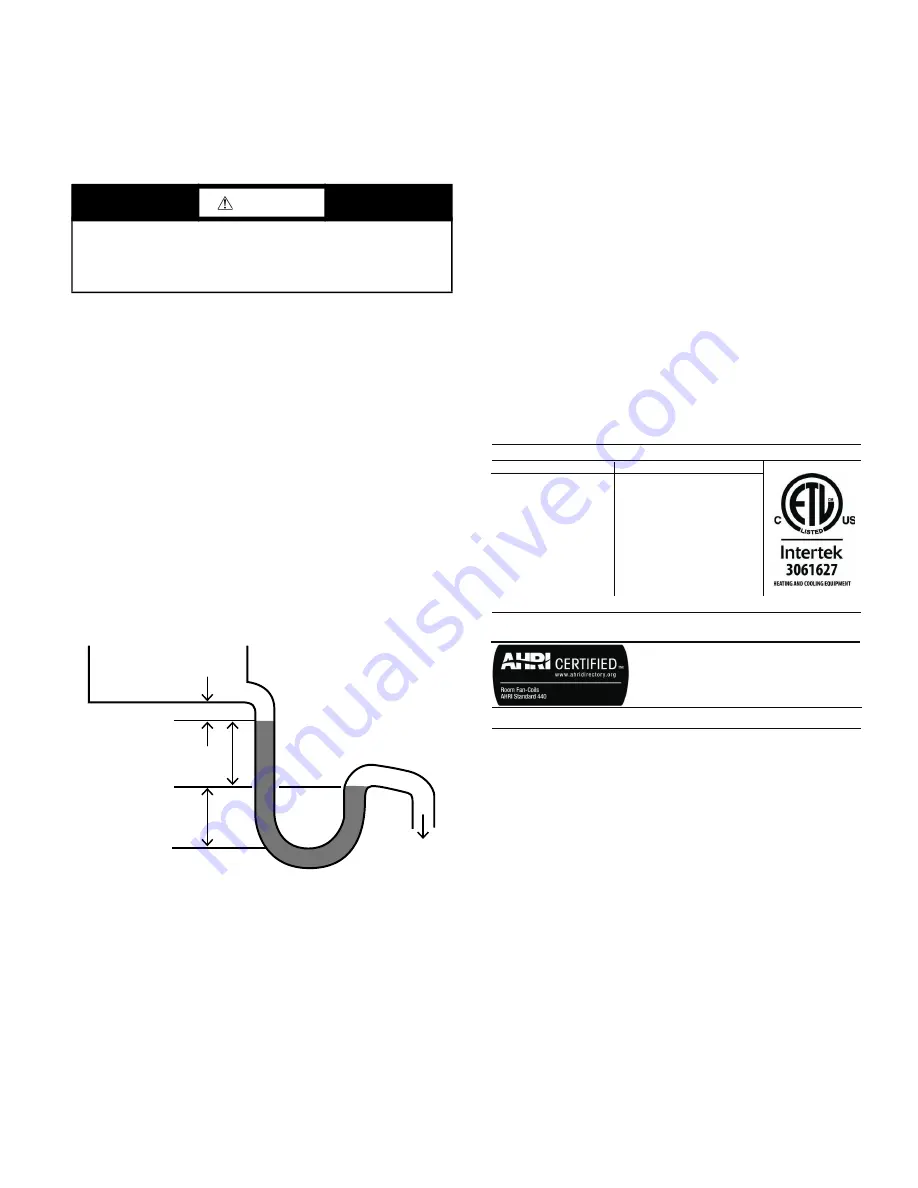

The drain U-trap should be deep enough to offset maximum unit

static pressure difference as shown at Fig. 26, to prevent conden

-

sate flowing back to drain pan.

Fig. 26 —

Condensate Drain U-Trap

CONDENSATE FLOAT SWITCH

The condensate float switch is used to detect clogged or restricted

condensate pan drains. The condensate switch uses a Normally

Closed contact to allow the system control power to pass through

the switch energizing the water valves and fans allowing normal

operation. When an overflow condition is detected by the switch,

it opens the NC contacts and de-energizes the water valves and

fans.

Step 4 — Make Electrical Connections

The unit serial plate lists the unit electrical characteristics includ

-

ing the required supply voltage, fan and heater amperage and re

-

quired circuit ampacity. (See Fig. 27.) The unit wiring diagram

displays all unit and field wiring. Every project is different and

each unit on a project may be different, the installer must be famil

-

iar with the wiring diagram and serial plate on the unit BEFORE

beginning any wiring.

Ensure all field electrical connections are in accordance with unit

wiring diagram and all applicable national and local code. The

type and size of all wiring and other electrical components includ

-

ing circuit breakers, disconnect switches, etc. shall be determined

by the individual job requirements. Verify conductor size is suit

-

able for the distance to the equipment connection and will support

the equipment electrical load. All installations including field

wiring shall be made in compliance with all governing codes and

ordinances. Compliance with all codes is the responsibility of the

installing contractor.

All components furnished for field installation by either the facto

-

ry or the controls contractor shall be located and checked for prop

-

er function and compatibility. Inspect all internal components for

shipping damage. Inspect all electrical connections within the unit

control box and accessories and tighten if necessary.

NOTE: All field wiring must be in accordance with governing

codes and ordinances. Any modification of unit wiring without

factory authorization will invalidate all factory warranties and

nullify any agency listings. The manufacturer assumes no respon

-

sibility for any damages and/or injuries resulting from improper

field installation and/or wiring.

Fig. 27 —

Serial Plate Example

CABINET/CONTROL BOX MAINTENANCE LIGHT

Optional Service Light provides a source of illumination in the

main unit cabinet and the control box during routine maintenance

and troubleshooting in the dark ceiling spaces. Light turns "ON"

when access panel or control box door is open, but unit is not pow

-

ered. (See Fig. 28.)

Step 5 — Connect Ductwork

All ductwork shall be installed in accordance with the project

plans and specifications. See Fig. 22-25 for supply and return duct

flanges location and dimensions.

NOTE: When installing units that attach to branch duct piping, use

industry approved duct standards and configuration such as those

published by Air Conditioning Contractors of America (ACCA)

or American Society of Heating, Refrigeration and Air Condition

-

ing Engineers (ASHRAE). The standards provide necessary infor

-

mation on sizing, layout and installing supply and return air duct

systems.

Flexible duct connections should be used on all air handling

equipment. All ductwork and insulation shall be installed to allow

proper access to all components for service and repair such as fil

-

ters, motor/blower assemblies, etc.

CAUTION

Protect all water coils from freezing after initial filling with

water. Even if the system is drained, unit coils may still hold

enough water to cause damage when exposed to temperatures

below freezing.

Drain Pan

Safety Margin

TSP

TSP

To Drain

Max Water Coil Leaving Air or Max Motor AMB:

Max Fuse or Max Circ Breaker (HACR Type NEC):

Unit Intended for Indoor Use Only & Suited For 0.00 Clearance From Combustible Surfaces

-

25A - SCCR: 5KA

Unit Serial No:

Model No:

42DHA20

776004-60-1

ELECTRICAL

ENV/PERF

Motor(s):

Motor VPH:

Motor FLA:

Heater AMPS:

QTY of Motor(s):

Motor HP:

Min Circ Amps:

Heater VPH:

E020-71537402

277/1/60

5.10A

18.1A

5.0 kW

1

1 HP

29.0A

277/1/60

Max ESP:

Max Inlet Water Temp:

Coil Test:

High Side Coil Design:

Refrigerant Type:

1.65

300 PSIG

-

-

Max Outlet Air Temp:

Max Hot Water or Steam:

ARI Model:

Low Side Coil Design:

-

42DHA20

-

190F

2 PSIG

Heater Kw:

Motor Current:

5.10A

Manufactured in the USA