19

CONNECTING THE ANTENNA

Connect an

ANS400

tuned antenna using a coaxial cable

RG58

(impedance

50

Ω)

with a maximum length of

15 m

.

1) Automatic

Selected by enabling automatic reclosing (Automatic reclosing "

ON

" on the display).

When the door is completely closed the opening command will start a complete cycle

which will end with automatic reclosing.

Automatic reclosing starts after the programmed pause period has elapsed (minimum

2 seconds) when the opening cycle has been completed or straight away after the

intervention of a photoelectric cell (the intervention of a photoelectric cell causes the

pause time to be reset).

During the pause time "

Pause

" will flash on the display along with the remaining

pause time.

pressing the blocking button during this period will stop automatic reclosing and

consequently stop the display from flashing. The indicator light remains lit until the

closing manoeuvre has terminated.

2) Semiautomatic

Selected by deactivating automatic reclosing (Automatic reclosing "

OFF

" on the

display). Work cycle control using separate opening and closing commands.

When the door has reached the completely open position the system will wait until it

receives a closing command either via an external control button or via radio control,

before completing the cycle.

The indicator light remains lit until the closing manoeuvre has terminated.

3) Manual manoeuvring with released motors

Releasing the motor the gate can be moved by hand; once the motor has been re-

engaged the programmer will recover the position after two consecutive attempts

to arrive at the travel limit.

4) Emergency manoeuvre

By default the emergency manoeuvre is disabled, to enable it move the jumper to

the position

J3

"ENABLE" (fig. 2). If the electronic programmer no longer responds

to commands due to a malfunction you may use the

EMRG1

or

EMRG2

inputs to

move the gate leaf manually (fig. 2). The

EMRG1

or

EMRG2

inputs directly com-

mand the motor without passing through the logic control.

Gate movement will be at normal speed and the direction depends on the installed

position of the motor:

- left-hand installed motor

EMRG1

closes and

EMRG2

opens;

- right-hand installed motor

EMRG1

opens and

EMRG2

closes.

Attention!

During the emergency manoeuvre all safety devices are

disabled and there is no gate positioning control: release the commands

before you are at the mechanical travel buffer. Only use the emergency

manoeuvre in cases of extreme necessity.

After you have carried out an emergency manoeuvre the electronic programmer will

lose the position of the gate ("out of pos" on the display) and therefore when normal

operation is restored it will carry out a repositioning manoeuvre.

•

If the "open-close" mode is set for the "

TD

" button (menu "OPTION") activating

the "

TAL

" button will start the limited opening stage (only from the completely

closed position) but while the gate is opening pressing the button again will

have no effect. Once the opening position has been reached pressing the "

TAL

"

button will start closing after which pressing "

TAL

" again will have no effect.

•

If the "open-block-close" mode is set for the "

TD

" button (menu "OPTION")

activating the "

TAL

" button will start the limited opening stage (only from the

completely closed position) pressing the button again will block the gate; press-

ing the button a third time will start the closing cycle. Pressing the "

TAL

" button

again will have no effect.

• If an opening command is received during limited opening; the limited opening

command will become a full opening command.

If the

FI

photocell cuts in during the closing stage you will only have partial

movement in the opening direction (It reopens only for the distance it has been

closing the gate).

•

Note:

The limited opening command can also be given using the second channel

radio function.

The limited opening distance is set to half of the entire opening distance.

This device allows the propulsion unit to work during blackouts.

• The programmer has a built in charger for an

NiMH 24V

battery that is managed

by a dedicated micro controller. The control chip adjusts the voltage according to

the condition of the connected battery.

To avoid the risk of overheating only use the battery supplied by the

manufacturer

SPN 999540

.

If the battery shows signs of damage it must be replaced immediately.

The battery must only be installed/removed by qualified personnel. Used

batteries must not be thrown into domestic rubbish bins and they must

be disposed of according to the local standards and regulations in force.

• The unit returns to normal operation once the power supply brought back on line.

To use the battery again it must first be allowed to recharge.

The battery charge time with a battery in good condition can take up to a maxi-

mum of

16 hours

. If the time required is greater you should consider replacing

the battery. You are however advised to replace the battery every three years.

• When the door has stopped, the controlled external devices (

CTRL 24 Vdc

) do not

receive power in order to increase the autonomy of the battery. When a command

is received however (

via radio

or

via cable

) the programmer sends power to the

controlled external devices and checks their security status. It follows therefore

that the command will be carried out (security devices at rest) with a one second

delay to give time to restore the correct operation of the devices. If after this period

a security device is found to be in alarm the command will not be carried out, power

to the external devices will be cut off and the programmer will return to stand-by.

Note!

If you wish to use an external receiver it must be wired to the binding posts

16-17 (fig. 3) otherwise a command sent

via radio

will not be able to activate the door.

• The self-sufficiency of the system when it is running on battery power is depend-

ent on the ambient conditions and on the load connected at binding posts 16-17

(power is always routed there during blackouts).

When the battery is completely flat (during blackouts) the programmer

will lose the position of the door and therefore when power returns (after

the first command given) you will have to carry out the repositioning

procedure (see page 21). For this reason you should avoid leaving the

electronic programmer without power

for lengthy periods (more

than two days).

• It is not possible to enter the programming mode when running off battery

power.

• During blackouts the battery supplies power to both the logic and the motor

control parts of the programmer.

For this reason during battery powered operation the voltage applied to the

motor is inferior to the voltage supplied during normal operation and the motor

will therefore work slower and will not decelerate when approaching the travel

limits.

Slot-in battery charger

The LED

L3

indicates the function mode as follows:

Off

: missing batteries or the electronic programmer is running

off battery power (during a blackout). During the first 10

seconds of operation from the start up of the electronic

programmer the battery charger is blocked. After this period

has elapsed it may either start self-diagnostics (indicated

by a lengthy flashing of the Led) or it will start recharging

(Led continuously lit);

Brief flashing:

voltage variation has been detected at the battery charger

binding posts (e.g. when the batteries are being connected

or removed);

Single flashing:

this repeats every 2 seconds indicating that the batteries

are being topped up to maintain their level;

Remains lit:

the batteries are charging. The charge time depends on a

number of factors and can last up to 16 hours. Using the

motor will increase the time needed for charging.

Battery check

With the gate in the completely closed position and the display switched off. Check

that LED "

L3

" (battery charging) is giving off

"one flash at a time"

.

Switch off the power at the mains and make sure that the display indicates that it is

working off battery power and that the charge is greater than 90%. Give a movement

command and measure the overall voltage

: The reading should be at least

22 Vdc

.

LIMITED OPENING (PEDESTRIAN ACCESS)

BATTERY POWERED OPERATION

FUNCTION MODES

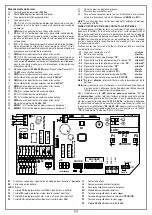

CS1256B

DC0450

L3

Scheda di innesto

PRG424BC

08-01-2008

DC0435

Description :

Product Code :

Date :

Drawing number :

P.J.Heath

CARDIN ELETTRONICA S.p.A

- 31020 San Vendemiano (TV) Italy - via Raffaello, 36 Tel: 0438/401818 Fax: 0438/401831

Draft :

All rights reserved. Unauthorised copying or use of the information contained in this document is punishable by law

Scheda carica batteria