3

△

Cooling system faults.

○

How to diagnose faults:

It should take approximate 3 hours to reach the lowest setting temperature of 5

℃

for an empty unit (assuming ambient

temp of 32 degrees centigrade and continuous operation). If not, check the compressor, cooling fans, controller, and sensors.

If all these are working normally, there is probably a cooling system

’

s fault.

○

How to repair the defualt

1. Check the compressor

Turn on the unit and check there is electricity current flowing to the compressor using a caliper type Amp meter, the

current should be within 0.6 to 2 Amps. If the readings are not in this range, turn off and cut off the pipes

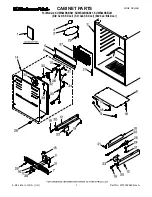

(See Fig.8

showing G)

and the seal pliers

(See Fig.8 showing E.)

from the compressor, then turn the unit on again (

in this case

only run the compressor for a few minuets, so as to avoid the compressor absorb moist air

) and recheck the

current and if there is pressure at the outlet pipe. If the current reading is still out of range specified above and no

pressure from the compressor outlet, replace the whole compressor.

2.

Check the cooling system pipe work:

Carefully check the cooling system after verifying the compressor is working normally. Then follow the procedure

below.

1>.

Then cut off process pipe and check the refrigerant. If there is not enough refrigerant, the defualt of the refrigerant

system should be caused by the leaking. If the refrigerant is sufficient., it is probably jamed in the capillary.

2>.If the default is concentrated on the cooling system, the checking procedure is as below.

A. Cut off the vent pipe of the compressor, and infuse 0.8-1MP nitrogen by

process pipe

, and please put the hand close

to the cut kerf of the vent pipe. If there is a little gas leak form the terminal, it means normal, or it is jamed.

B. Make sure the capilary is working normally, when the drainpipe is connetced again, and infuse 0.8-1MP nitrogen

then test the leakage if the cooling system of the soldering point with the soap water. Check from the the soldering

point arround the compressor

(Fig.8 & Fig.9

、

Fig.9.1)

, and if everything is ok, remove the air-duct board and chech

the soldering point around evaporator

(Fig.6 & Fig.7)

. please see the remove method and the procedure as below

.

(Fig.1, Fig.2 ,Fig.3,Fig.4 & Fig.5)

C. If all the soldering point in B is not leaking, there are two possibility, one is leakage in the inner condenser, another

is the damage on the parts

(

such as evaporator,condenser and so on

)

in the cooling system. If it is the inner damage,

it can not be repaired, and if the damage on the parts, replace them.

3>. Make sure that there is not leakage in the cooling system, refill the refrigerant.

3. Refill the refrigerant:

1>. Using the vacuum pump form a vacuum in the system, via the joint of the low-pressure process pipe on the compressor ,

the high-pressure pipeline is on the process pipe of the filter. Apply the vacuum pump for approximately 20 minutes. Until

the vacuum is lower than 100Pa. Then solder the compressor process pipe of the filter. Keep the vacuum running while

soldering this joint

2>.

Fill Cooling system with refrigerant via the process pipe. (The refrigerant is R134a. Regarding refrigerant quantity

Please refer to the instruction at back label of wine cellar). Then solder the compressor process pipe after the system is

charged with refrigerant.

4. Running test:

Replace all the components after the procedures above and turn the unit on. To verify the effectiveness of the repair,

monitor