(2) New Functions

1. Remaining ink level detection function

This printer has a function to detect the remaining ink level. (Default setting: OFF)

Detection method: Dot counting (counted for each Bk/Cl ink tank)

Cl tank: The remaining ink level is detected by total counted dot values of 3 color ink tanks

Display method:

Displayed on the Status Monitor (displayed at 3 levels shown below for each Bk/Cl ink tank)

Level 1: Half level of remaining ink level (approx. 40%)

Level 2: "!" mark is indicated. (Approx. 20% of remaining ink level)

Level 3: "?" mark is indicated. (Remaining ink level is unclear)

* Remaining ink detection function displays the status only, and does not cause errors.

Accuracy:

The margin of error of detection accuracy is plus or minus 10% in normal printing

*The margin of error is likely to be large in the following specific print patterns:

When printing continuously using an only single-color ink tank

As the remaining ink level is calculated by total counted dot values of 3 color ink

tanks, if either C/M/Y ink is heavily consumed, the margin of error increases.

When performing continuous Bk solid printing, the margin of error for remaining

ink is large.

With continuous printing ink flow from the tank to the ink chamber can be

interrupted, after which ink remains unused in the tank and will not flow again.

Procedures for display:

Perform the following operations from the printer driver utility:

1) Set the indication of the remaining ink level in "Low Ink Warning Setting."

2) Reset the ink counter in "Ink Counter Reset."

* Be sure to reset the ink counter from the printer driver utility after replacing ink tanks.

<Expected trouble with this function>

1) Due to user error, the actual remaining ink level does not accord with the indicated remaining

ink level, resulting in "ink out," etc.

User error: Forgetting to reset ink counter / ink counter reset apart from when replacing ink tanks

2) Due to the specific print pattern, the actual remaining ink level does not accord with the indicated remaining ink

level, resulting in "ink out."

Specific print pattern: Continuous printing using single-color ink tank only / continuous Bk solid printing, etc.

2. Print control change according to temperature/paper type

As this printer performs the most suitable printing for the temperature environment and print mode (print paper), the

control of pre-printing ink ejection varies.

"Low temperature below 15 degrees" or "other":

To obtain steady print quality, the pre-printing ink ejection is controled at every line.

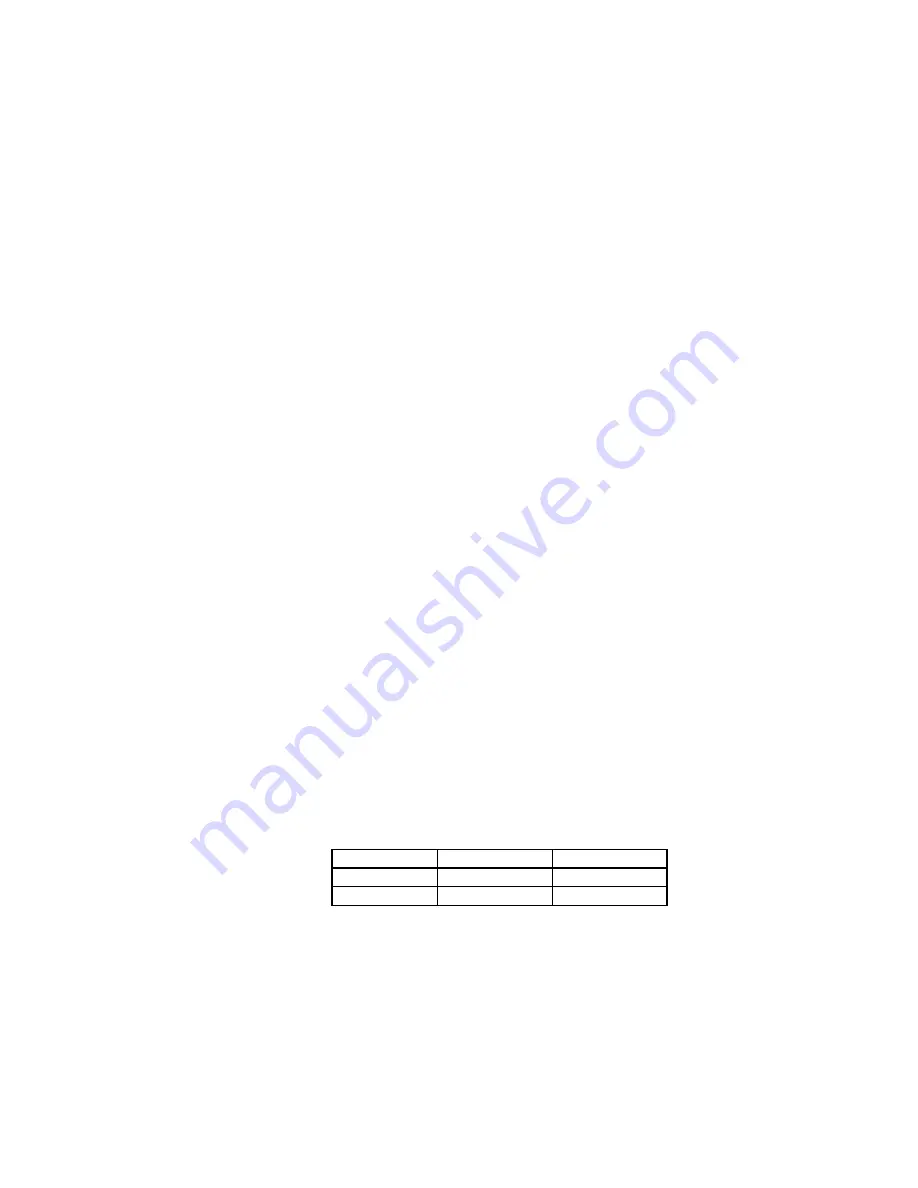

Print mode

Under approx. 15

o

C Over approx. 15

o

C

Plain paper

Every line

Dot count

Other

Every line

Every line

<Expected trouble with this function>

1) When selecting plain paper print mode:

Print speed is reduced to approx. one-third of normal in a low temperature environment (under approx. 15 degrees)

2) When selecting plain paper print mode:

The max. number of sheets printable decreases (the amount of ink consumed increases a little) in a low

temperature environment (under approx. 15 degrees).