(2) Periodic maintenance

No periodic maintenance is necessary.

(3) Periodic replacement parts

There are no parts in this printer that require periodic replacement by a service engineer.

(4) Replacement consumables

There are no consumables that require replacement by a service engineer.

1-2. Customer Maintenance

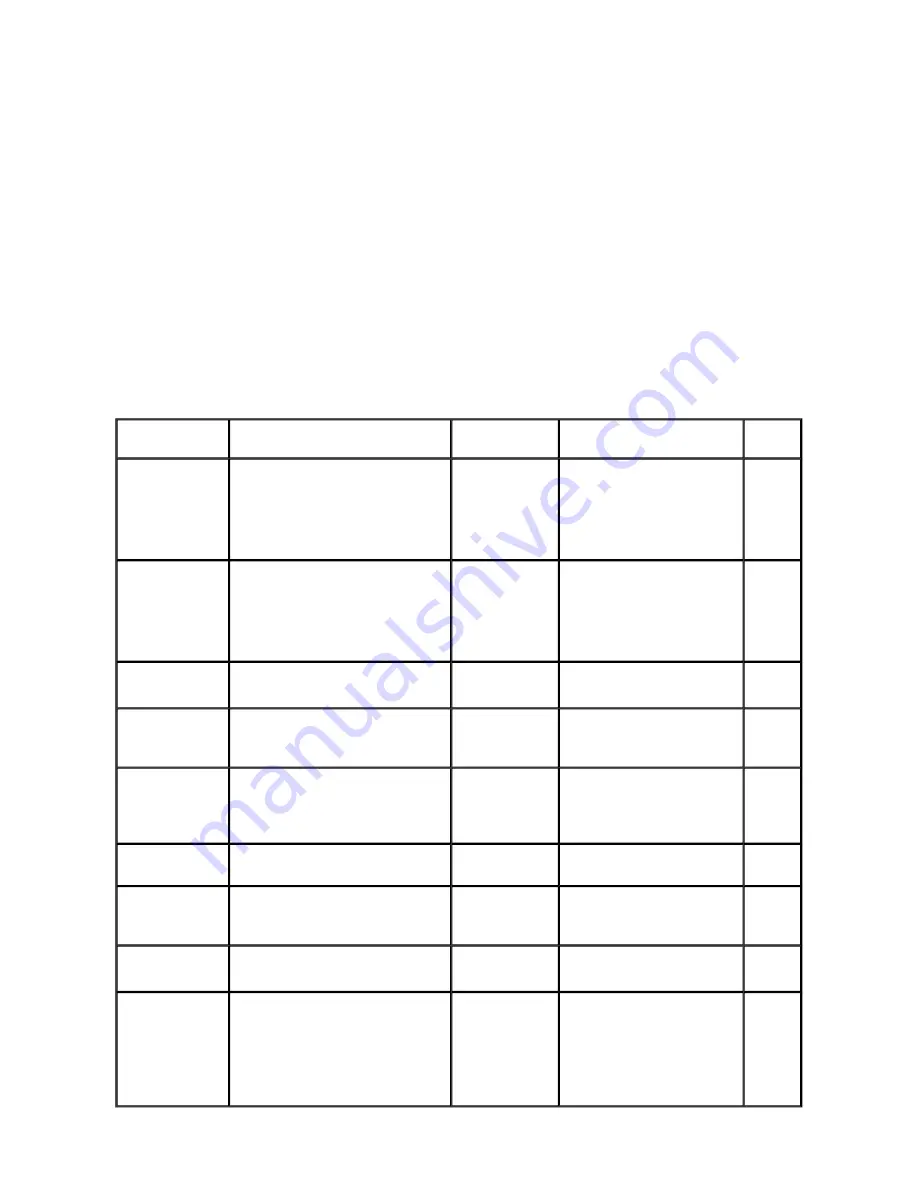

Adjustment

Timing

Purpose

Tool

Approx.

time

Automatic print

head alignment

- At print head replacement

- When print quality is not satisfying,

and not improved by print head

cleaning.

To secure the dot

placement

accuracy.

- 2 sheets of Matte Photo Paper

(MP-101)

- Printer buttons

- Computer (automatic

alignment via printer driver)

13 min.

Manual print head

alignment

- At print head replacement

- When print quality is not satisfying,

and not improved by print head

cleaning.

To secure the dot

placement

accuracy.

- 5 sheets of plain paper

- Printer buttons

- Computer (printer driver with

the manual print head

alignment selected)

15 min.

Print head

cleaning

When print quality is not satisfying.

To improve

nozzle conditions.

- Printer buttons

- Computer (printer driver)

1 min.

Print head deep

cleaning

When print quality is not satisfying,

and not improved by print head

cleaning.

To improve

nozzle conditions.

- Computer (printer driver)

2 min.

Ink tank

replacement

When an ink tank becomes empty.

("No ink error" displayed on the

monitor, or short flashing of an ink

tank LED)

―

―

2 min.

Paper feed roller

cleaning

When paper does not feed properly.

To clean the

paper feed rollers.

- Printer buttons

2 min.

CD / DVD print

position

adjustment

At CD / DVD printing, when

necessary.

To correct CD /

DVD print

position.

- Computer (application

software)

5 min.

Bottom plate

cleaning

When the back side of the paper is

smeared.

To clean the

platen ribs.

- Plain paper

- Computer (printer driver)

1 min.

ASF sub- roller

cleaning

When the paper fed from the ASF is

smeared due to ink mist attached to the

ASF sub-rollers.

To clean the ASF

sub-rollers.

- Plain paper

- Printer buttons

See Part 2, 4. FAQ, How to

make and set the ASF sub-

roller cleaning sheet, for

details.

1 min.

Summary of Contents for PIXMA IP5300

Page 4: ...2 2 Carriage Board Print Head Connector 3 PIXMA iP5300 SPECIFICATIONS II TABLE OF CONTENTS ...

Page 5: ...Part 1 MAINTENANCE PIXMA iP5300 TABLE OF CONTENTS ...

Page 18: ... Part 1 3 1 Notes on Service Part Replacement ...

Page 27: ......

Page 28: ... Part 1 3 3 Adjustment Settings 1 2 ...

Page 35: ......

Page 38: ......

Page 39: ......

Page 40: ... Part 1 3 3 Adjustment Settings 3 to 5 ...

Page 42: ... Service test sample ...

Page 43: ......

Page 47: ...Part 2 TECHNICAL REFERENCE PIXMA iP5300 TABLE OF CONTENTS ...

Page 50: ... Part 2 1 NEW TECHNOLOGIES ...

Page 53: ...Capping time 30 sec 60 sec 2 2 CLEANING MODE AND AMOUNT OF INK PURGED ...

Page 63: ...Part 3 APPENDIX PIXMA iP5300 TABLE OF CONTENTS ...

Page 64: ...1 BLOCK DIAGRAM 1 1 iP5300 PDF file for print Part 3 APPENDIX TABLE OF CONTENTS ...

Page 65: ......

Page 66: ... Part 3 1 BLOCK DIAGRAM ...