HTTP://WWW.FIXCLUB.COM.CN

Chapter 2

2-23

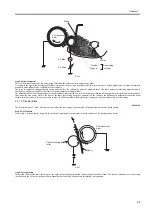

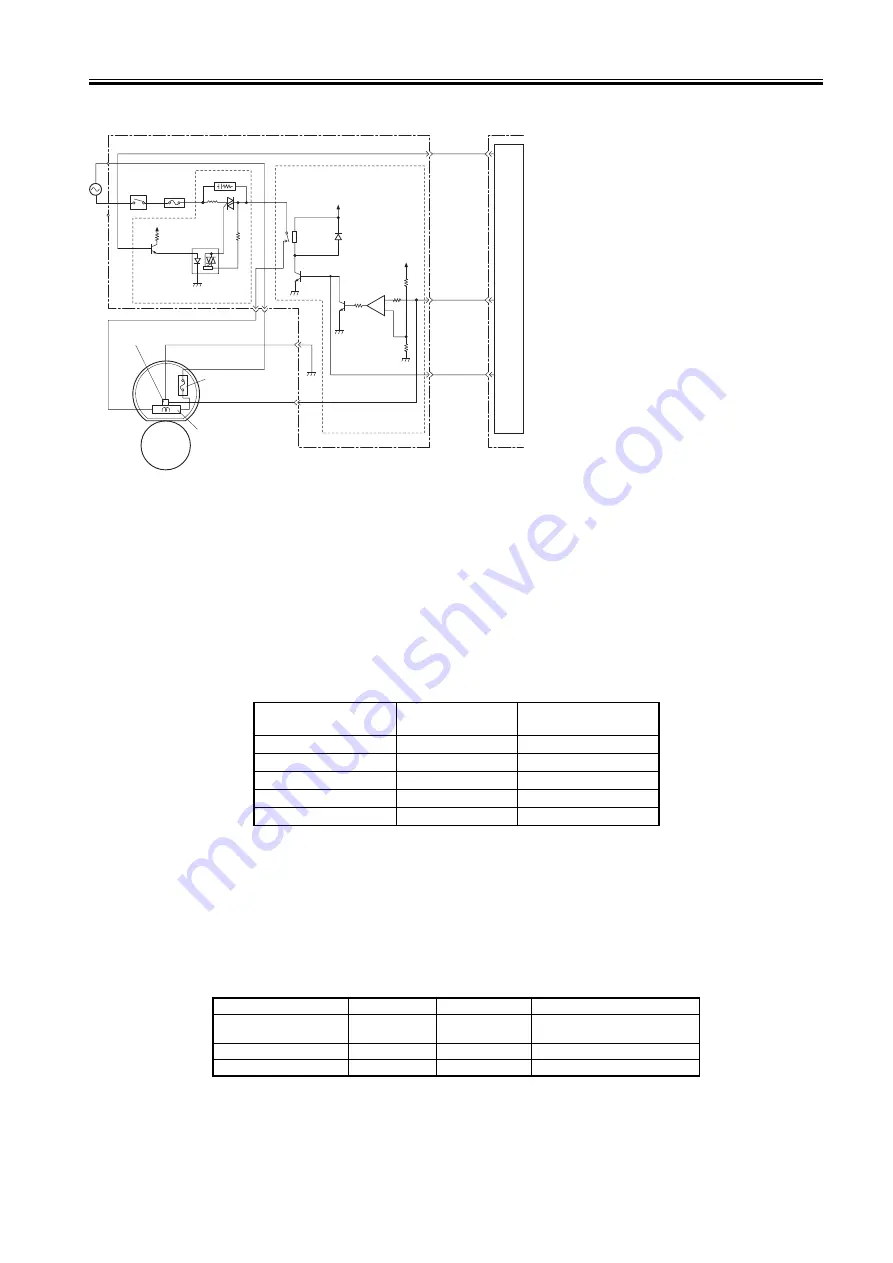

F-2-25

The surface temperature of the fixing heater is monitored by the thermistor (TH1) that remains in contact with the fixing heater. The resistance of the

thermistor decreases in response to increases in the surface temperature of the fixing heater, causing the voltage of the fixing heater temperature detection

single (FSRTH) to change.

The CPU (IC902) found inside the engine controller monitors the signal (FSRTH), and generates the fixing heater drive signal (FSRD) according to the

voltage of the signal operating in conjunction with the CPU. The fixing heater drive circuit, on the other hand, uses the signal to control the fixing heater

so that the temperature of the fixing heater remains at a specific level.

The machine executes the following 4 control mechanisms according to the temperature of the fixing heater and the size of the selected paper:

1. start-up temperature control; from when the print command arrives at the engine control to when the fixing heater reaches the target temperature.

2. paper passage temperature control; during printing so that the temperature of the fixing heater is identical the target temperature.

The target temperature may be any of 5 settings, used according to the selected fixing mode. Any of these modes is selected according to the settings of

the driver and such parameters as paper size and the number of printouts.

The following shows the relationship between the paper type setting and the fixing mode in relation to the fixing target temperature:

T-2-5

3. sheet-to-sheet temperature control; between sheets during continuous printing so that the temperature of the fixing heater is lower than the target

temperature, thus preventing overheating of the fixing film.

4. down sequence; during continuous printing so as to prevent overheating of the edges of the heater.

In this control, the CPU of the engine controller checks the length and width of paper; if the size of the paper matches a specific set of conditions, the

machine is shifted to long narrow mode (Note) or small paper mode regardless of the settings of the driver.

In this mode, the CPU forces the printing speed to decrease conversely increasing the distance between sheets, thereby increasing the sensitivity of the

thermistor located in the middle of the fixing heater and, consequently, preventing the edges of the heater from overheating.

The following shows the relationship between the printing speed and the conditions used to make a shift to this mode:

T-2-6

Paper type selected for

driver

Fixing mode

Fixing target temperature

Plain paper

Normal

165 to 175 deg C

Heavy paper

Rough

180 to 190 deg C

Heavy paper H

Extra

180 deg C

Transparency, plain paper L Local

150 deg C

Envelope

Envelope

165 to 175 deg C

Down-sequence mode

Paper length

Power width

Printing speed (ppm)

No down sequence (normal

state)

267.4 mm or more 197 mm or more

Number of printouts according to

paper size

Small size paper mode

267.4 mm or less

197 mm or less

8-->6-->4

Long narrow paper mode

267.4 mm or more 197 mm or less

3

+

-

Thermal fuse (TP1)

J302-4

J302-3

J303-1

Fixing film unit

J303-3

+3.3V

SSR101

Q102

Fuse

(FU101)

Power supply PCB

Power

switch

(SW101)

IC902

CPU

Engine controller PCB

Thermistor (TH1)

Q103

Relay

(RL101)

+24V

FSRD

+24V

IC501

J201-19 J902-5

RLYD

J201-21 J902-3

FSRTH

J201-20 J902-4

Fixing control circuit

Fixing heater safety circuit

Fixing heater (H1)

Q104

Pressure roller

Fixing heater drive circuit

Summary of Contents for LBP-3000

Page 1: ...H T T P W W W F I X C L U B C O M C N Mar 10 2005 Service Manual LBP3000 2900 Series LBP2900 ...

Page 2: ...H T T P W W W F I X C L U B C O M C N ...

Page 6: ...H T T P W W W F I X C L U B C O M C N ...

Page 12: ...H T T P W W W F I X C L U B C O M C N Contents ...

Page 13: ...H T T P W W W F I X C L U B C O M C N Chapter 1 PRODUCT DESCRIPTION ...

Page 14: ...H T T P W W W F I X C L U B C O M C N ...

Page 16: ...H T T P W W W F I X C L U B C O M C N ...

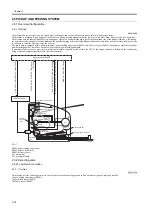

Page 23: ...H T T P W W W F I X C L U B C O M C N Chapter 2 TECHNICAL REFERENCE ...

Page 24: ...H T T P W W W F I X C L U B C O M C N ...

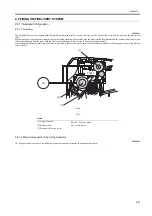

Page 44: ...H T T P W W W F I X C L U B C O M C N Chapter 2 2 18 ...

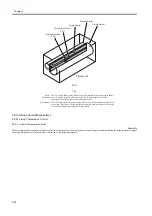

Page 51: ...H T T P W W W F I X C L U B C O M C N Chapter 3 DISASSEMBLY AND ASSEMBLY ...

Page 52: ...H T T P W W W F I X C L U B C O M C N ...

Page 87: ...H T T P W W W F I X C L U B C O M C N Chapter 3 3 33 F 3 161 ...

Page 88: ...H T T P W W W F I X C L U B C O M C N ...

Page 89: ...H T T P W W W F I X C L U B C O M C N Chapter 4 MAINTENANCE AND INSPECTION ...

Page 90: ...H T T P W W W F I X C L U B C O M C N ...

Page 92: ...H T T P W W W F I X C L U B C O M C N ...

Page 98: ...H T T P W W W F I X C L U B C O M C N ...

Page 99: ...H T T P W W W F I X C L U B C O M C N Chapter 5 TROUBLESHOOTING ...

Page 100: ...H T T P W W W F I X C L U B C O M C N ...

Page 102: ...H T T P W W W F I X C L U B C O M C N ...

Page 107: ...H T T P W W W F I X C L U B C O M C N Chapter 6 APPENDIX ...

Page 108: ...H T T P W W W F I X C L U B C O M C N ...

Page 110: ...H T T P W W W F I X C L U B C O M C N ...

Page 117: ...H T T P W W W F I X C L U B C O M C N Mar 10 2005 ...