A-9

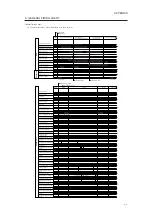

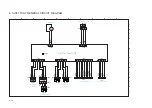

C. General Circuit Diagram

N

M

L

K

J

I

H

G

F

E

D

C

B

A

N

M

L

K

J

I

H

G

F

E

D

C

B

A

Keypad

PCB D

1 2 3

1 2 3

1 2 3

1 2

1 2

1

1

2

2

1

2

3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

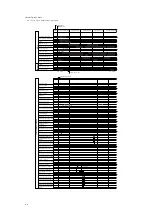

J110

J110B

J110A

A17

B17

A9

B9

9

8

7

6

5

4

3

2

1

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

J545

PS16

J546

PS27

J542

P18

J543

PS14

J544

PS22

J547F

J547M

J547

SL

SL4

A9

B9

J541

A9

B9

A9

B9

9

8

7

6

5

4

3

2

1

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

J535

PS15

J536

PS26

J532

PS17

J533

PS13

J534

PS21

J537F

J537M

J537

SL

SL3

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

J531

J531BF

J531BM

J531AF

J531AM

J541BF

J541BM

J541AF

J541AM

0V

C3L

TP

5V

0V

C3PD

5V

0V

C4PD

5V

0V

C3R

TD

5V

0V

C4R

TD

5V

0V

C3OP

VP3PD

C3PUSD*

24V

5V

0V

24V

0V

C4OP

C4PUSD*

24V

5V

0V

VP4PD

5V

0V

C4L

TP

5V

Cassette 3

lifter sensor

Cassette 3

paper sensor

Cassette 3

open/closed

sensor

Cassette 3

re-try sensor

Vertical path 3

paper sensor

Cassette 3

pickup solenoid

Cassette 4

lifter sensor

Cassette 4

paper sensor

Cassette 4

open/closed

sensor

Cassette 4

re-try sensor

Vertical path 4

paper sensor

Cassette 4

pickup solenoid

J719

J9013

J9013M

J9013F

J3502

J3504

J704

J701

1 2 3 4

1 2 3 4 5 6

1 2 3

1 2 3 4

1 2

4 3 2 1

J4009

J4008

1 2 3 4

4 3 2 1

J4004

J4005

1

2

3

4

1

2

3

4

1 2 3 4 5

J4007

J8500F

J4016

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10 11

1 2 3 4 5

J4017

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

J4003

1 2

1

2

3 4 5 6 7

1 2 3

J703A

J707M

J707F

1 2 3 4 5 6 7 8

1 2 3 4

J703B

J703C

J101

8 7 6 5 4 3 2 1

J321F

1 2 3 4 5

2 1

2 1

2 1

J4013

J4002

J4006

1 2 3

J4014

J4015

2

1

2 1

1 2 3 4 5 6 7

J702A

1 2 3 4 5 6 7 8

7 6 5 4 3 2 1

J719F

J702B

1 2 3 4

J702C

J325F

PCB8

For FINISHER

1

2

3

4

5

6

7

8

9

12

11

13

14

15

16

17

18

19

20

21

22

10

1

2

3

4

5

6

7

8

9

12

11

13

14

15

16

17

18

19

20

21

22

10

PCB2

5V

GND

HDD_12V

HDD_GND

HDD_GND

HDD_5V

GND

0V

24V

0V

0V

24V

24V

GND

24V

GND<J1026-3>

GND<J9005-6>

GND<J9005-7>

GND<J9005-8>

GND<J9005-9>

GND<J9005-10>

GND<J1020-6>

GND<J1020-7>

GND<J1020-8>

GND<J1020-9>

GND<J1020-10>

GND<J1020-14>

GND<J1020-15>

5V<J1026-1>

GND<J1026-4>

5V<J1026-2>

3.3V

A2<J9005-1>

<J881-1>

<J881-2>

3.3V

A1<J1020-1>

3.3V

A1<J1020-2>

3.3V

A1<J1020-3>

3.3V

A1<J1020-4>

3.3V

A1<J1020-5>

3.3VB<J1020-11>

3.3VB<J1020-12>

3.3VB<J1020-31>

3.3V

A2<J9005-2>

3.3V

A2<J9005-3>

3.3V

A2<J9005-4>

3.3V

A2<J9005-5>

FAN_ON

FAN_DETECT

TRA

Y_5V

TRA

Y_0V

TRA

Y_24V

TRA

Y_0V

DCOM_24VU

DCOM_0V

DCOM_12V

DCOM_GND

DCOM_5V

DCOM_0V

DCOM_3.3V

A

DCOM_0VU2

GND

REMO

T

GND<J1021-3>

RMT_2<J1021-2>

RMT_1<J1021-1>

24V

GND

24V

GND

Power cord base

TEST_GND

TEST_12V

FIN_TXD

FIN_RXD

FIN_O

VR2

EN*

S-DIN

RX-LO

AD

DOUT

TX-END

MO

TOR-CLK

S-CLK

FT23

FT22

SW1

J1F

4

3

2

1

4

3

2

1

J1M

4

3

2

1

3

2

1

2

1

2

1

0

2

6

1

4

8

J714F

FT25B

FT27

FT13 FT14

FT11

FT16

FT12

FT17

FT15

FT18

FT25A

FT24

FT26

FT27

TP1

T P

H2

H1

FT872

FT871

MT2

MT8

123

123

123

123

J1501M

J1501

J1504M

J1504

1 2 3

1 2 3

1 2 3

1 2 3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

J2M

J2F

J3F

J3M

W1

W2

PCB7

1 2 3 4 5 6

1 2 3 4 5 6

J5M

1 2 3 4 5 6 7 8

1 2

12

12

3 4 5 6

J5F

H3

AP KIT

MT5

MT6

FT28

FT29

1 2 3

ET5

ET6

ET2

ET4

J7M

J7F

J10M

J10F

J9M

J9F

H4

H5

1

2

1

2

PLG1

FT1B

FT2

FT3

FT4

ELCB

LF1

PLG1A

FT1A

FT2A

MT1

FT3A

FT4A

ELCB

LF1A

PLG1B

FT1B

FT2B

FT3B

FT4B

FT9

FT10

ELCB

LF1B

MT3

ET7

FT21

FT20

FT19

SW3

100V/15A

230V/10A

120V/20A

1

2

3

J3501

J4001

J6M

J6F

FT7

FT5

FT8

FT6A

FT6B

RL1

To Earth

For Earth

OL1

PCB3

AC driver

PCB

J2051

J2053

Drum heater

Drum heater

control PCB

Paper deck

heater

(accessory)

Cassette

heater

UL1865

A

WG22

Fixing main heater

Fixing sub heater

Environment

switch

ON

OFF

J9007F

FT101

FT100

1

2

3

ON OFF

Cassette

heater switch

ET3

Main

power

switch

Accessories power

supply PCB

DC power supply PCB

J1401F

1 2

2 1

J4010

J8503F

GND

24V

1 2

2 1

J4011

J8502F

GND

24V

To paper deck

24V

GND

24V

GND

J103M

J103F

A15

B15

A15

B15

J103

J103AF

J103BF

J103AM

J103A

J103B

J103BM

A15

B15

J151

J151M

J151F

2 1

1 2

J162

J162M

J162F

3 2 1

1 2 3

J193

J193M

J193F

2 1

1 2

J163

J163M

J163F

4 3 2 1

1 2 3 4

J192

J192F

J192M

3 2 1

1 2 3

J191

J191F

J191M

LA1

M7

2 1

1 2

M6

M

J103C

2

1

3

J155

J155M

J155F

2 1

1 2

J160

J160M 2 1

11

12

4

5

6

8

9

10

7

M

J154

J154M

J154F

4 3 2 1

1 2 3 4

12

13

14

15

J3 4 3 2 1

1 2 3 4

2 3

1

4 5

1

2

3

4

5

6

7

8

9

10

11

M10

M

J158

J158M

J158F

2 1

1 2

M9

M

S4

S6

S5

TS1

J156

J156M

J156F

3 2 1

1 2 3

S1

S3

S2

TS2

J161

J161M

J161F

3 2 1

1 2 3

3 2 1

13

14

15

FM2

J157

3 2 1

PS3

J2

J1

2 3 4 5

VS1

J5570

PCB6

6

6

J153M

J153F

J153

7 6 5 4 3 2 1

1 2 3 4 5 6 7

AP KIT

PTRCM1

PTRCM2

24V

PEXP*

PCLM1

PCLM2

5V

0V

DTEP

FR

ONT_DOOR_DETECT

0V

0V

FM2ON

FM2CLK

24V

0V

P

OTO

N

PO

T-DT

Potential control PCB

24V

24V

M10ON

M9ON

TEP

5V

0V

0V

MFDS

5V

Pre-transfer

charging

wire cleaning

motor

Pre-exposure

LED

Primary charging

wire cleaning motor

Potential

sensor

Hopper

supply

motor

Hopper

toner

sensor

Hopper

stirring

motor

Primary

charging

cooling fan

Developing

assembly

toner sensor

1

1 2 3

4

5

6

3 1

2

4 5

6

J159

J159M

J159F

J9010M

J9010F

J9010

Manual feed

tray open/

closed sensor

2

J104

J104A

J104B

J105

A20

B20

13

J2101

J2101A

J2101B

J2108

J2106

J2105

A20

B20

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

6 5 4 3 2 1

J411

1 2 3 4 5 6

M

M11

6 5 4 3 2 1

J412

1 2 3 4 5 6

M

M26

6 5 4 3 2 1

J414

1 2 3 4 5 6

M

M17

6 5 4 3 2 1

1 2 3 4 5 6

M

M25

M

M12

M

M

M27

6 5 4 3 2 1

J417

1 2 3 4 5 6

M24

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

2

3

4

5

6

1

2

13

12

11

10

9

8

7

6

5

4

3

2

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

1 2

1 2 3 4 5

3 4

6

12 13

10

16

15

17 18

14

1 2 3 4 5 6 7 8 9

2

3

4

5

6

1

2

6

2

3

4

5

6

1

2

6

2

3

4

5

6

1

2

7

7

J411F

J411M

J412F

J412M

J414F

J414M

J413M

J413F

J417M

J417F

2

3

4

1

2

J2112

J2102

13

4

6

J2104

J2110

J2103

SL

SL6

M5

M

~

M4

M

~

2 1

1 2

1 2

1 2

6 5

4 3

2 1

J421

J421F

J421M

J419M

J418F

J1401M

J2109

<J2109-1>

<J2109-2>

<J2109-3>

<J2109-1>

<J1401M-1>

<J1401M-2>

<J1401M-3>

<J1401M-4>

5V

GND

GND

24V

M4_A

M4_A*

M4_B

M4_B*

M4_DO

WN1

M4_DO

WN2

M12_DO

WN1

M12_DO

WN2

M17_DO

WN1

M17_DO

WN2

M12_A

M12_A*

M12_B

M12_B*

M17_A

M17_A*

M17_B

M17_B*

M27_A

M27_A*

M27_B

M27_B*

M26_A

M26_A*

M26_B

M26_B*

M13_A

M13_A*

M13_B

M13_B*

M21_ON

M20_ON

C3LMD

0V

C4LMD

0V

M4_ON

M5_ON

M25_A

M25_A*

M25_B

M25_B*

M24_A

M24_A*

M24_B

M24_B*

M24_DO

WN2

M24_DO

WN1

M27_DO

WN2

M27_DO

WN1

M26_DO

WN2

M26_DO

WN1

M25_DO

WN2

M25_DO

WN1

M13_DO

WN2

M13_DO

WN1

RDPUSD_ON

GND

RDLM

GND

LDLM

RDPUSD*

24V

M11_B*

24V

M11_B

M11_A

24V

M11_A*

M26_B*

24V

M26_B

M26_A

24V

M26_A*

M17_B*

24V

M17_B

M17_A

24V

M17_A*

M25_B*

24V

M25_B

M25_A

24V

M25_A*

M12_B*

24V

M12_B

M12_A

24V

M12_A*

M27_B*

24V

M27_B

M27_A

24V

M27_A*

M24_B*

24V

M24_B

M24_A

24V

M24_A*

Right deck

pickup motor

Vertical

path upper

motor

Pre-registration

motor

Vertical path

duplex/

feeding motor

Cassette 3/4

pickup motor

Vertical path

lower motor

Left deck

pickup motor

Right deck

lifter motor

Left deck

lifter motor

Right deck

pickup solenoid

PCB4

Motor driver PCB

IDS

DSJ

AM

24V

FCBSD*

CBOP

TH1

0V

TH2

M_19LD

5V

0V

FM5DT

0V

FM5_ON

M_19BREAK

M19_ON

GND

CJ

AM

EDS

4

A20

B20

B20

A20

GND

5V

M19_0V J321F-6

M19_24V J321F-5

J251CF

J251BF

J251

AF

J106B

J119

J106A

J106

J118

FT32

MT30

GND

FUSER RELA

Y 24V

TEST_GND

TEST_12V

J704M

J714F

Fixing drawer connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

4 3 2 1

1 2

1 2

1 2

J107

J107A

J107B

A18

B18

J222AF

J222BF

J222FC

J222MC

A16

B16

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

17

18

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

1

2

3

4

A12

B12

6 5 4 3 2 1

1 2 3 4 5 6

M

M18

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

A16

4

4

B16

A16

B16

SL

SL8

2 1

J224

J224M

J224F

J235

J236

1 2

2 1

J712

J712M

J712F

1 2

1

2

3

4

J222F

MSW1

J222AM

J222BM

J222M

1 2 3 4

10 11 12 13 14 15

1 2 3 4 5 6 7 8 9

1

1

4

3

2

2 3 4

1

2

3

4

5

1 2 3 4 5

J231

J231F

J231M

J228F

J228 M

6 5 4 3 2 1

1 2 3 4 5 6

M

M14

J228

6 5 4 3 2 1

1 2 3 4 5 6

1 2 3 4 5 6

M

M29

J233

J233M

J233F

J226

J226M

J2305

J2301

J226F

J1513

PS37

1 2 3

1 2 3

1 2 3

1

2

3

1

2

3

4 5 6 7 8 9

1

2

3

1

2

3

4

5

6

4

5

6

7

8

9

J2307

J2303

J2302

J2302A

J2302B

J2306

J2306A

J2306B

6 5 4 3 2 1

1 2 3 4 5 6

J234

J234M

J234F

1 2 3 4 5 6

M

J230

J230F

J230M

J229

J229F

J229M

M16

1 2 3

1

2

3

1

2

3

J225

PS33

PS31

J223

J223F

J223M

PS38

J1516

J225M

J225F

PS34

PS30

PCB9

M16_A*

M16_B*

M18_A

M18_A*

M18_B

FM8CLK

M18_DO

WN2

M18_DO

WN1

M29_A

M29_A*

M29_B

FM8ON

M29_DO

WN2

M29_DO

WN1

GND

FM8_CLK

LDPFS

M14_A

M14_A*

M14

_B

M14_B*

M14_DO

WN2

M14_DO

WN1

M16_A

M16_B

M16_ON

R

VFSD2*

DSRFPD

DPDS

R

VS1

R

VS2

DGRFPD

WTFL*

GND

FT725

FT725

GND

GND

GND

GND

LDPD

5V

GND

5V

5V

5V

5V

24V

R

VFSD2*

Duplex

horizontal

registration

sensor

Duplex

registration

motor

Left deck

feeding

paper sensor

Reversal

sensor 2

Reversal

flapper

solenoid

Duplex

paper

sensor

Duplex

pre-registration

sensor

Waste

toner

screw lock

detection

Duplex feed

right motor

Reversal motor

Reversal sensor 1

Duplex feeding

left motor

5V

0V

24V

0V

TRA

Y_5V

TRA

Y_0V

TRA

Y_24V

TRA

Y_0V

J1518

M18_B*

24V

M18_B

M18_A

24V

M18_A*

M14_B*

24V

M14_B

M14_A

24V

M14_A*

M16_B*

M16_B

M16_A

24V

24V

M16_A*

M29_B*

24V

M29_B

M29_A

24V

M29_A*

R

VS1

GND

5V

1 2 3

FM8

Duplex feeding fan

J232

J232M

J232F

FM8ON

FM8CLK

GND

DGRFPD

DPDS

R

VS2

DSRGPD

J108

J108A

J108B

A12

B12

1

5

6

7

8

9

10

11

12

2

3

4

1

2

3

4

5

6

7

8

J726

J726M

J726M

J713

J713M

J713F

J727

J727M

J727F

J6320

J6320M

J6320F

J631

J729

J729M

J729F

J728

CL

CL3

J715

CL

CL1

J725

J725M

J725F

FM4

M2

9

10

11

12

J602

J601

M1

S16

S17

S17

SVR1

PS23

SL

SL2

J632

J6310F

J6310M

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

1

1

2

1

2

3

1

1 2 3

2

1

1

2

1

1

2

2

2

3

1

2

3

1

2

3

1 2

1 2

1 2

1 2

4

1

2

3

4

1

2

3

4

4

3

2

1

3

2

1

2

FM4CLK

Manual feed

release solenoid

Manual

feed

paper

sensor

Manual feed paper

width detection

Manual

feed

pickup

clutch

Developing

clutch

Drum motor

Main motor

Controller

cooling fan

<J321-1>24V

<J321-2>0V

J321-1 24V

J321-2 0V

FM4ON

0V

MMFG

MMON

5V

0V

DMFG

DMON

5V

0V

24V

DEVCD*

24V

MFLSD*

24V

5V

MFDS

0V

5V

MFPCD*

MFPD

0V

J102

J102B

J102A

A16

B16

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

10 11 12 13

4

5

SL7

2 1

1 2

J566

J566M

J566F

J4502

PCB5

HVT PCB

J4503

J7371M

J7371F

S11

S13

S15

S12

S14

L1

HVT

transformer

W3

W4B

W4A

W5

W6

SEPARATE

TRANSFER

PRIMAR

Y/GRID

POST R

OLLER

J4002

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

J701M

SL

1 2

1 2

3 4 5

1

2

3

4

5

1

2

3

4

5

1

2

3

2

1

3

2

1

3

6 7 8 9

Left deck

pickup

solenoid

GND

FM6LCK

FM6ON

PR/TR-REMO

TE

PT/SP-REMO

TE

SP-CNT

PT/SP-CNT

TR-CNT

PR-CNT

HVT_HH_REMO

TE

DEV

-A

C-REMO

TE

DEV

-DC-CNT

HV

-CR-REMO

TE

PT/SP-LEAK-DETECT

TR-LEAK-DETECT

PR-LEAK-DETECT

FINTXD

FINRXD

OV

24V

LDPUSD*

0V

DRAM_HT_ON

SHRD*

SHRD

MHRD*

MHSD

CASSETTE_HT_ON

12V

J111

J111B

J111A

A10

B10

9

J718

J718F

J718M

FM3

1

2

3

4

5

6

7

8

9

10

1

J719M

J577

J577M

J577F

J8505

2

3

J5500

SVR4

3

4

1

2

5

6

7

8

9

J550

SVR5

S27

S29

S28

S30

SV1

J5770

J5770M

J5770F

4

5

6

7

8

9

10

S31

S33

S32

S34

SV2

2

1

3

2

1

3

2

1

3

4 5 6 7

3 2 1

2

1

3

2

1

1 2 3 4

4 3 2 1

1 2 3 4

4 3 2 1

3

Cassette 3

paper width

detection

Cassette 4 paper

width detection

(100V model only)

Cassette 4

length detection

(100V model only)

Cassette 3

length

detection

S-CLK

MOTOR_CLK

TX_END

DOUT

RX-LOAD

S-DIN

EN*

FM3CLK

GND

FM3ON

0V

C3PWD

5V

0V

C4PWD

5V

0V

C4PL0

C4PL1

5V

0V

C3PL0

C3PL1

5V

Heat

discharging

fan

EX/DOM* DETECT

J125

FM1

J109

1

2

3

FM1ON

0V

FM1CLK

Feeding fan

J113

J113B

J113A

A15

B15

10

A15

B15

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

11

12

4

5

6

1

2

3

15

14

13

12

11

10

9

8

7

6

5

4

1

2

3

4

5

6

7

8

9

10

11

12

3

13

2

14

1

15

1

2

3

4

5

6

7

8

9

10

11

10

11

12

13

14

15

J801M

A15

B15

J801F

J801

J804

J804F

J804M

J805F

J805M

J802

J802F

J802M

M20

M

J805

M21

M

J803

J803F

J803M

J1523

J1521

PS25

J807

J807F

J807M

J1519

PS28

PS24

HU1

J8492

2

1

3

3 2 1

3 2 1

1 2 3

1 2

1 2

1 2 3

J806

SVR2

1 2 3

1 2 3

2 1

2 1

2

3

1

J9004

J9004F

J9004M

1 2 3

2

3

1

1 2 3

1 2 3

1 2 3

2

3

1

2

3

1

2

3

1

J9003

1 2 3

1 2 3

0V

VD2PD

5V

VD1PD

HUM OUT

5V

0V

LODOP

0V

5V

LODOP

LWRPD

C3PLV

C4PLV

C3LMD

C4LMD

TH

0V

Vertical

path 2

paper sensor

Vertical

path 1

paper sensor

Cassette 3

lifter

motor

Cassette 4

lifter

motor

Cassette 3

level

detection

7

8

9

J810

SVR3

1 2 3

J9006

J9006F

J9006M

J9008F

J9008M

J9003F

J9003M

J9008

Cassette 4

level

detection

15

14

13

12

J809

J809F

J809M

J8508

PS2

4

4

1

1 2 3 4 5

2 3

1 2 3

2

3

1

Right lower

cover open/

closed

sensor

C3LMD

0V

C4LMD

0V

0V

VD2PD_SENSOR

5V

0V

VD1PD

5V

GND

TH

GND

HUM_OUT

5V

0V

C3PLV

5V

0V

C4PLV

5V

0V

LWRPD

5V

13

14

15

4 3 2 1

4 3 2 1

4 3 2 1

4

5

3 2 1

J114

J123

J124

J201M

J201F

J101

J102

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5

1 2 3

1 2 3

1 2 3 4 5 6 7 8 9 10

J202F

10 9 8 7 6 5 4 3 2 1

5 4 3 2 1

3 2 1

J202M

J1543M

J1543F

J1541M

J1541F

J1542M

J1542F

FM7

HDD fan

Environment

sensor

Laser write

start sensor

2

1

3

4

5

6

7

8

J202

J1541

J1542

Shift tray PCB

5V

GND

24V

GND

FULLON

SCW

SCCW

SPFULL*

SPEXIST*

STHPL

STHPR

STCNCT*

GND

GND

GND

GND

GND

FM7ON

FM7CLK

FM7_DETECT

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

J115

J115A

J115B

A15

B15

15

9

8

7

6

5

4

3

2

1

15

14

13

12

11

10

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

J567

PS11

J568

PS20

15

7

8

9

10

11

12

13

14

15

J569

PS9

J561

J561F

J561M

J564

PS12

J565

PS10

1

2

3

4

5

6

J571

J5700

PS47

J572

PS48

1

6

5

4

3

2

1

1

2

3

4

5

6

3

2

1

3

2

1

2

1

1

2

2

3

4

5

6

J573

J5701

J5701M

J5701F

J5700M

J5700F

PS49

J574

PS50

7

6

5

4

3

2

1

1

2

3

4

5

6

3

2

1

3

2

1

8

9

13

14

15

10

11

12

CL

J717M

J717

J717F

CL4

0V

LDEL

5V

0V

LDL

TP

5V

0V

LDPD

5V

0V

LDR

T

5V

0V

LDEOP

5V

0V

0V

RDPD1

RDPD2

5V

5V

0V

0V

LDPD1

LDPD1

5V

5V

24V

LDCLD*

Left deck

limit

sensor

Left deck

lifter

sensor

Left deck

paper

sensor

Left deck

re-try

sensor

Left deck open/

closed sensor

Right deck

level

sensor

(upper)

Right deck

level sensor

(lower)

Left deck

level

sensor

(upper)

Left deck

level sensor

(lower)

Left deck

pull-off

clutch

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

J112

J112B

J112A

A9

B9

A9

B9

A9

B9

9

8

7

6

5

4

3

2

1

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

J516

PS5

J517

PS8

J512

PS6

J513

PS7

J515

PS19

2

3

4

5

6

7

8

9

1

1

2

3

4

5

6

7

8

9

J518

PS32

J511

J511AF

J511BF

J511AM

J511BM

J511M

J511F

0V

RDEL

5V

0V

RDL

TP

5V

0V

RDPD

5V

0V

RDR

T

5V

0V

RDEOP

5V

RDPFS

5V

0V

Right deck

lifter

sensor

Right deck

paper

sensor

Right deck

re-try sensor

Right deck

open/

closed

sensor

Right deck

feeding

paper sensor

Right deck

limit

sensor

J201

J401F

J401M

J201F

J201M

J401

J9000

J9000M

J9000F

J1023

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

5

4

3

2

1

5

4

3

2

1

4

3

2

1

4

3

2

1

4 3 2 1

4 3 2 1

4 3 2 1

4

5

3

2 1

4

5

3

2 1

1

2

3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

J1015

J1015B

J1015A

J122

J122B

J122A

J121

J2501

J2502

J117

J116

J120

J2511

J2701

40

40

J1012

A15

B15

J6505

J6505B

J6505A

A15

B15

J1018

J1018B

J1018A

J1012B

J1012A

A18

B18

J6801

J6801B

J6801A

A18

B18

40

40

1

2

3

4

5

6

7

8

9

10

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

10

9

8

7

6

5

4

3

2

1

11

11

11

11

6

5

4

3

2

1

1

2

11

10

9

8

7

1

8

17

16

15

14

13

20

19

PCB14

PCB11

PCB20

J10

PCB10

B/W

COLOR

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

J1017

40

40

1

2

3

4

5

6

7

1

2

3

4

1

2

3

4

10

1

2

1

2

3

4

5

6

7

8

9

10 11 12

1 2 3 4 5 6 7 8 9

2 1

3

12 11 10 9 8 7 6 5 4

1

2

3

4

5

6

7

8

1 2 3 4 5 6 7 8

1

12

2 3 4 5 6 7 8

J8503

J8503M

J1538

J9012F

J9012M

J1022

1

1 2 3 4

2

3

4

1

2

3

4

J1060

J1024

J1533

J1532

1 2 3 4

1

2

3

4

J1534M

J1534F

J1534

J1551

J1552

J1402M

J1530

M15

GND

24V

LMSPSEL

LMRD

Y*

LMON

5V

BDIN*

GND

THERM-

THERM+

GND

5V

HEA

TER_ON

24V

GND

LZ_LDPSEL1

LD-DT

GND

LD-EN

SMALE1

LSH

GND

3.3V

GND

L-RD

Y

LD(-)

LD(-)

GND

Laser scanner

motor

BD PCB

PVD<14>

GND

PVD<12>

GND

PVD<10>

GND

PVD<8>

GND

PVD<6>

GND

PVD<4>

GND

PVD<2>

GND

GND

GND

GND

PVD<0>

PHSYNC

PVCKL

PPI<5>

GND

PPI<4>

GND

GND

GND

GND

GND

PPI<3>

GND

PPI<2>

GND

PPI<1>

GND

GND

PPI<0>

PPR

TST

PSTS

PCTS

PCPRD

Y

GND

PVD<15>

GND

PVD<13>

GND

PVD<11>

GND

PVD<9>

GND

PVD<7>

GND

PVD<5>

GND

PVD<3>

GND

GND

GND

GND

PVD<1>

PBD

PVREQ

PP0<4>

GND

PP0<3>

GND

GND

GND

GND

GND

PSCNST

GND

PPO<2>

GND

PPO<1>

GND

PPO<0>

PCMD

PR

TS

PPRD

Y

PR

O

W

OR

5V

GND

GND

ZO_ADD

ANR

OM_CS

ZO_ADD

ANR

OM_SCK

ZO_ADD

ANR

OM_DIN

ZI_ADD

ANR

OM_DOUT

GND

GND

ZI_ADD

ANR

OM_CNCTN

5V

TXDC

5V

CONT_RESET

GND

GND

GND

FPFRAME

LCDPWR

FPD

AT

0

GND

FPD

AT

2

GND

FPD

AT

4

GND

GND

FPD

AT

6

SOFTSWC

3.3V

A1

GND

FPD

AT

7

GND

FPD

AT

5

GND

FPD

AT

3

GND

GND

GND

GND

FPD

AT

1

FPLINE

LCDON

5V

5V

RXDC

FPHIFT

5V

5V

GND

CONT

-RESET

UISOFTSW

ONDCLK

IUOD0

GND

IUOD1

GND

IUOD2

GND

GND

IUOD3

GND

TXDM

GND

RXDM

GND

IOLCDEN

GND

IOLCDF

GND

IOSP

GND

IOLP

LCDON

3.3VB

Main controller PCB

Control panel PCB

GND

GND

GND

RXD

TXD

COUNT

COUNT

5V

DETECT

5V

COUNT

CARD_DETECT

5V

GND

GND

RXD

TXD

COUNT

5V

GND

24VA

GND

GND

GND

GND

IDED7

IDED8

IDED6

IDED9

IDED5

IDED10

IDED4

IDED11

IDED3

IDED12

IDED2

IDED13

IDED1

IDED14

IDED0

IDED15

NC

NC

NC

NC

IDEDMREQ

GND

GND

GND

GND

GND

IDEIO

W

IDEIOR

IDERD

Y

CONT

-RESET

IDEDMA

CK

IDEINT

IDEA1

IDEA0

IDEA2

CS1

CS3

NC

GND

SR

TS

GND

SCTS

GND

SVSYNC

GND

SPO[1]

GND

SPI[0]

GND

GND

GND

GND

GND

GND

SPI[2]

SCPRD

Y

SPRD

Y

SVD[0]

GND

SVD[2]

GND

SVD[4]

GND

SVD[6]

GND

SVD[8]

GND

SVD[10]

GND

SVD[12]

GND

GND

GND

GND

SVD[14]

SCMD

SSTS

NC

NC

GND

NC

NC

5V

GND

NC

NC

AP-LD

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

ODD0

ODD1

ODD2

ODD3

ODD4

ODD5

ODD6

ODD7

EVEN0

EVEN1

EVEN2

EVEN3

GND

EVEN4

EVEN5

EVEN6

EVEN7

VCLK

RING_CLK

RING_SIN

RING_LD

RSYNC

GND

SHSYNC

GND

GND

SPO[0]

GND

SPO[2]

GND

GND

GND

GND

GND

GND

GND

SPI[1]

SVCLK

SPO

WER

SVD[1]

GND

SVD[3]

GND

SVD[5]

GND

SVD[7]

GND

SVD[9]

GND

SVD[11]

GND

SVD[13]

GND

GND

GND

GND

SVD[15]

SSCNST

SPR

TST

1 2 3 4

1 2 3 4

J5002

J5112

6

5

4

3

J5012

J5052

J5052F

J5052M

J5051F

J5051M

J5051

2

1

1

2

3

3

2

1

1

2

3

3

2

1

J5113

J5003

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

40

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

1

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

40

1

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

40

1

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

J1014C

J1014B

J1014A

40

40

J5004

J5004B

J5004A

40

40

40

40

PCB13

J5056

PS40

J5057

PS39

1

2

3

1

2

3

J5062

1

2

3

4

5

4

3

J5007

J5101

J5062M

J5062F

5

1 2 3 4

2

1

1

2

3

4

5

4

3

5

1

2

3

4

2

1

J5102

4

3

2

1

J5053

PS43

1 2 3

3

4

J5006

J5053M

J5053F

1

2

3

4

1

2

1

7

2 3 4

6 5 4 3

J5010

J5105A

5 6

2 1

7

2 1

3 2 1

LA2

PCB18

+24V

GND

GND

GND

RX

TX

IT

OP*

+5V

+5V

+5V

+5V

TX

RX

GND

12V

GND

GND

GND

GND

GND

HPSENS

ADFOPEN*

5V

D_SENS3*

+24V

GND

LAMP_ON

INV_ERR

Original size

detection 3

Inverter PCB

Serial number

PCB

Laser driver PCB

Coin vendor

(accessory)

J9016

J9016M

J9016F

Control Card

IV (accessory)

Scanning lamp

(Xenon tube)

Scanner home

position sensor

Copyboard

cover sensor

3

2

1

3 2 1

J5601

J5002

J5001

2

1

2

1

2

1

2

1

Fuse PCB

Lens heater

Mirror heater

M34

J5105

J5005

J9009M

J9009F

J8500M

+24V

GND

+24V

GND

PCB12

Reader controller PCB

CCD/AP PCB

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

8

7

6

5

4

3

2

1

6

5

4

3

2

1

2 1

1

2

3

4

5

6

1

2

3

4

1

2

3

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1 2

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9 10 11

1 2 3 4 5 6 7 8 9 10

1 2

For FOOT SW

J6510

J6604

J6502

J6509

J6504

J6601

J6602

J6501

J6603

J6605

J956

J6508

J6506

J6507

J6503

J955

Control panel CPU PCB

PCB17

VEE

VR

VLCD

GND

L_R

TN3

K_R

TN7

L_DGT2

K_DGT2

MSW_IP

GND

L_R

TN2

K_R

TN2

L_DGT2

K_DGT2

+5V

BKL T

O

N

TTP-U

TTP-R

TTP-D

TTP-L

VLCD

VEE

VEE

GND

XSCL

LP

YD

DF

DOFF*

D3

D2

D1

D0

K_DGT0

K_DGT4

K_DGT2

L_DGT3

L_DGT7

L_DGT5

K_R

TN5

K_R

TN1

GND

L_R

TN2

L_R

TN0

K_R

TN2

K_R

TN1

K_R

TN0

L_DGT3

L_DGT2

L_DGT1

L_DGT0

K_DGT7

K_DGT6

K_DGT5

K_DGT4

K_DGT3

K_DGT2

K_DGT1

K_DGT0

GND

+3.3V

GND

GND

Keypad

PCB B

Keypad

PCB C

LCD contrast

adjustment

PCB

Touch panel

Keypad PCB A

1 2 3

J5008

8

1

2

3

1 2 3

1

2

3

4

5

6

7

8

9

1

2

3

4

1

2

3

4

5

6

7

8

9

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

5

6

7

8

9

8

7

6

5

4

3

2

1

4

3

2

1

1

2

3

4

J1413

J903

J902

J1543

Anti-rush current PCB

GND

24V

24V

24V

24V

24V

HVT 24V

INTERLOCK 24V

FR

ONT 24V

24V

MUL

TI 24V

24V

GND

GND

TRA

Y 24V

GND

TRAY 5V

TRA

Y_24V

TRA

Y_0V

J1414M

J1414F

J322F

J322M

J1415M

J1415F

<J222FC-1>

<J222FC-2>

<J222FC-3>

<J222FC-4>

<J4004-1>

<J4004-2>

<J4004-3>

<J4004-4>

J1402F

1

2

3

4

1

2

1

2

1

2

1 2

1

2

3

4

J1404M

J1404F

J1405F

J1405M

J160F

J323M

J323F

HDD_5V

HDD_12V

GND

GND

GND

GND

HVT_24V

J321M

M19-GND

M19-24V

M1-GND

M2-GND

M1-24V

M2-24V

A

WG24

A

WG18

J323

MSW2

1 2

SW2

Manual feed cover open/

closed detection

Front door

switch

T/SCLM1

T/SCLM2

24V

SL1P*

SL1R*

12V

24V

J273

J264

PS46

J259

PS36

24V

RGCD*

GND

RGPD

5V

T/SCLM2

T/SCLM1

24V

SL1R*

SL1P*

12V

FFUS*

J252

J254

J260F

J260

J260M

J252M

J283

J252F

J258F

SL5

J258

J258M

J255F

J255

J255M

J262

PS29

M

J261F

J261

J261M

J254F

J254M

CL

CL2

SL

J265M

J265

J265F

SL

J271F

MSW3

J271

J271M

24V

FCBSD*

GND

CBOP

FM5DT

0V

FM5ON

5V

M19BREAK

M19LD

M19ON

GND

CJ

AM

5V

GND

IDS

5V

GND

24V

5V

GND

TH1

0V

TH2

0V

J253

J253M

J253F

J268

J268M

J268F

M13

24V

R

VFSD2*

GND

DSJ

AM

5V

GND

EDS

5V

J256

J284

J286

J289

J612

J611

PS4

J257

PS35

J274

J274F

J274M

PS45

J263M

SL9

J263

J263F

SL

TH1

J270F

FM5

J270

J270M

J267M

J267

J267F

TH2

M19

B13

A13

J282B

J282A

J282

DSJ

AM

IDS

24V

FCBSD*

CBOP

TH1

0V

TH2

M19LD

0V

FM5DT

0V

FM5ON

M19ON

GND

CJ

AM

EDS

FFUS*

RGPD

24V

RGCD*

R

VFSD2*

14

B20

A20

4

J251AM J251

BM

J251CM

5V

5V

GND

GND

24VU

J288

J285

M

TM701

TM702

to earth

FUSER/FEED UNIT

to earth

REGI/SE_TR UNIT

FT33

M31

J281

20

J287

Delivery motor

Registration

roller clutch

Registration

paper sensor

Transfer/

separation

charging

wire

cleaning

motor

Fixing

assembly

inlet guide

drive

solenoid

Fixing/

feeding

lock

sensor

Reversal

flapper

solenoid

Delivery assembly

jam sensor

Fixing web

solenoid

External

delivery

sensor

Internal

delivery

sensor

Fixing web

length sensor

Fixing main

thermistor

Fixing

sub

thermistor

De-curling fan

Claw jam

sensor

Fixing/feeding relay PCB

PCB23

Fixing motor

M8

SL1

J2002

J2M

J2F

J9007M

Relay

SW4

J704F

J701F

M32

M33

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

1

2

1

2

1

2

3

1

2

3

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

1

2

1

2

1

2

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

4

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

14

14

13

12

11

10

9

8

7

6

5

4

3

2

1

13

12

11

10

9

8

7

6

5

4

3

2

1

4

3

2

1

3

2

1

2

1

3

2

1

1

2

3

3

2

1

10

9

8

7

6

5

4

3

2

1

2

1

2

1

2

1

1

2

2

1

8

7

6

5

4

3

2

1

13

12

11

10

9

8

7

6

5

4

3

2

1

7

6

5

4

3

2

1

3

2

1

1

2

3

3

2

1

2

1

2

1

5

6

7

8

1

2

3

4

9

10

11

12

13

14

15

16

17

18

19

20

14

13

12

11

18

19

20

17

16

15

10

9

8

7

6

13

12

11

10

9

8

7

6

5

4

3

2

1

5

4

3

2

1

13

12

11

10

9

8

7

6

5

4

3

2

1

4

3

2

1

15

16

17

18

19

20

PCB24

Remote Diagnostic

Device II (accessory)

J5009

H6

H7

J15100M

J15100F

J15101M

J15101F

PCB21

ET10

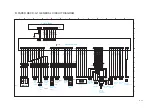

PCB1

DC Controller PCB

3

2

1

1

2

3

4

J1026

1

2

3

4

5

6

7

8

9

10

J9005

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

J1020

J1021

GND<J4016-3>

GND<J4017

-6>

GND<J4017-7>

GND<J4017-8>

GND<J4017-9>

GND<J4017-10>

GND<J4014-6>

GND<J4014-7>

GND<J4014-8>

GND<J4014-9>

GND<J4014-10>

GND<J4014-14>

GND<J4014-15>

GND

5V<J4016-1>

GND<J4016-4>

5V<J4016-2>

3.3V

A2<J4017-1>

3.3V

A1<J4014-1>

3.3V

A1<J4014-2>

3.3V

A1<J4014-3>

3.3V

A1<J4014-4>

3.3V

A1<J4014-5>

3.3VB<J4014-11>

3.3VB<J4014-12>

3.3VB<J4014-13>

3.3V

A2<J4017-2>

3.3V

A2<J4017-3>

3.3V

A2<J4017-4>

3.3V

A2<J4017

-5>

RMT_1

RMT_2

Relay PCB

Capacitor PCB

PCB22

M-18

F-12

I-3

M-19

H-21

J-18

J-19

H-20

M-8

E-8

E-2

M-7

F-7

J-2

I-1

H-20

H-21

J-2

M-9

D-17

D-17

F-19

D-16

D-19

H-7

L-8

D-20

L-8

G-18

D-20

D-18

E-10

F-14

F-17

G-7

E-2

E-2

E-8

F-16

K-17

M-8

E-18

B-20

E-18

E-18

E-15

F-17

L-8

G-18

L-7

F-7

I-2

<J322M-1>

<J322M-2>

<J322M-3>

<J322M-4>

<J321F-4>

<J321F-3>

T/SCLM1

24V

SL1P*

SL1R*

24V

T/SCLM2

RGCD*

RGPD

FFUS*

M13_B*

24V

M13_A*

M13_A

24V

24V

M13_B

R

VFSD2*

12V

0V

5V

5V

0V

5V

0V

5V

0V

5V

0V

0V

0V

5V

To ADF

To ADF

6 5 4 3

J5011

2 1

M3

M

M3_A

M3_A*

M3_B

M3_B*

+24V

+24V

Scanner motor

1 2

1 2

J2062

Hard disk

Duplex driver PCB

Not found in 120V model

Standard 100V model only

1

2

3

4

1 2 3 4 5 6

6 5 4 3 2 1

3

2

1

1

2

3

J715M

J715F

J8502M

J801AF

J801BF

J801AM

J801BM

Not found in

120V model

3

2

1

Summary of Contents for IR5000 - iR B/W Laser

Page 72: ...CHAPTER 2 STANDARDS AND ADJUSTMENTS 2 52 Blank Page ...

Page 104: ......

Page 224: ......

Page 234: ......