CHAPTER 3 DISASSEMBLY & REASSEMBLY

I. EXTERNAL

PARTS

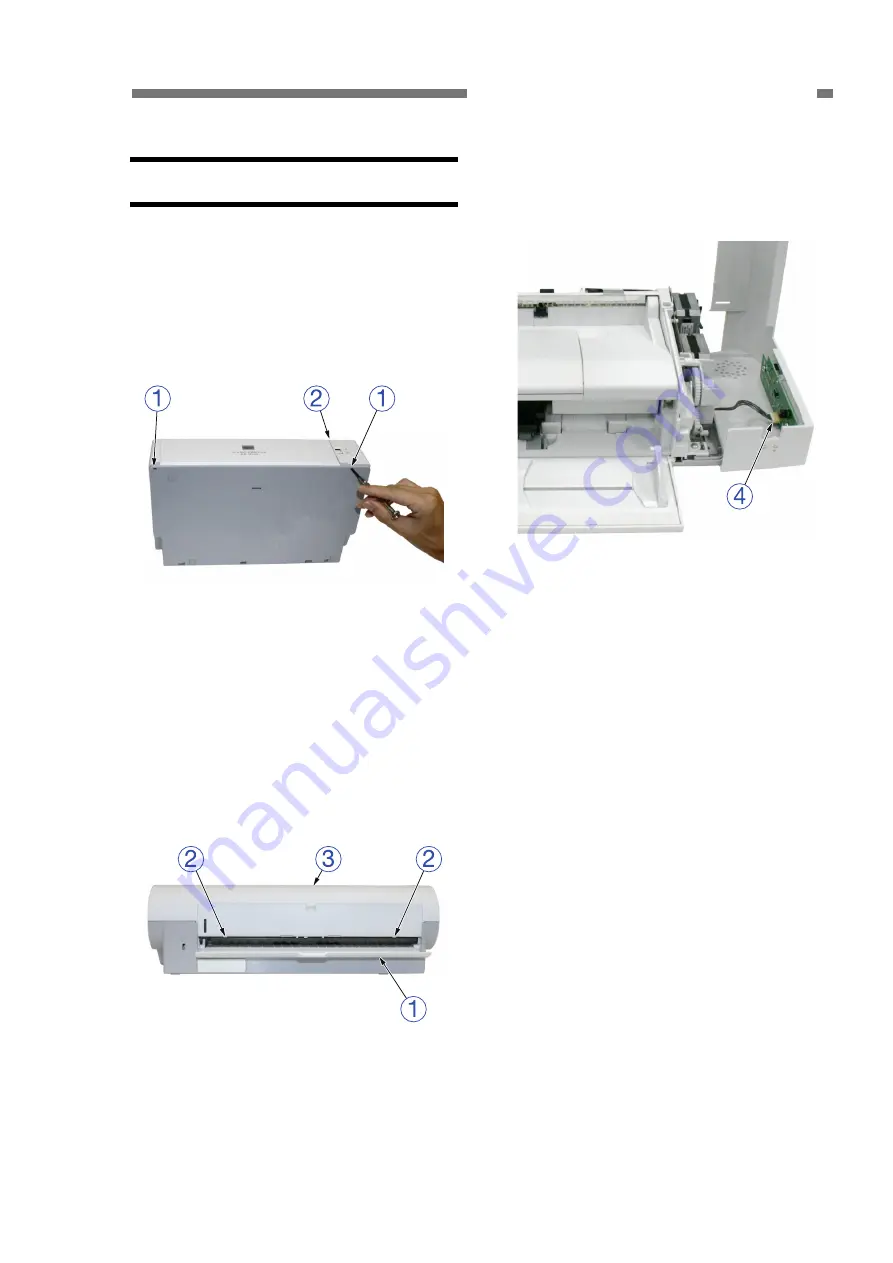

1. Upper Cover

1) Stand up the main body, insert a tool into

the 2 holes

{

1

on the left and right side

of the bottom cover, and slightly lift up

the front side of the upper cover

{

2

to

unhook the fitting parts.

Figure 3-101

2) Return the main body to horizontal and

open the straight path tray

{

1

. Unhook

the 2 pairs of fitting parts

{

2

on the left

and right side and remove the upper

cover

{

3

. Take care because there is a

cable connected to the back of the

control panel. Then, remove the

connector

{

4

.

Figure 3-102

Figure 3-103

Notes on assembling

Connect the cable before attaching the

upper cover. Do not get the cables

caught in parts. Furthermore, align the

position with the rear side bottom cover.

COPYRIGHT

©

CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

3-1