12

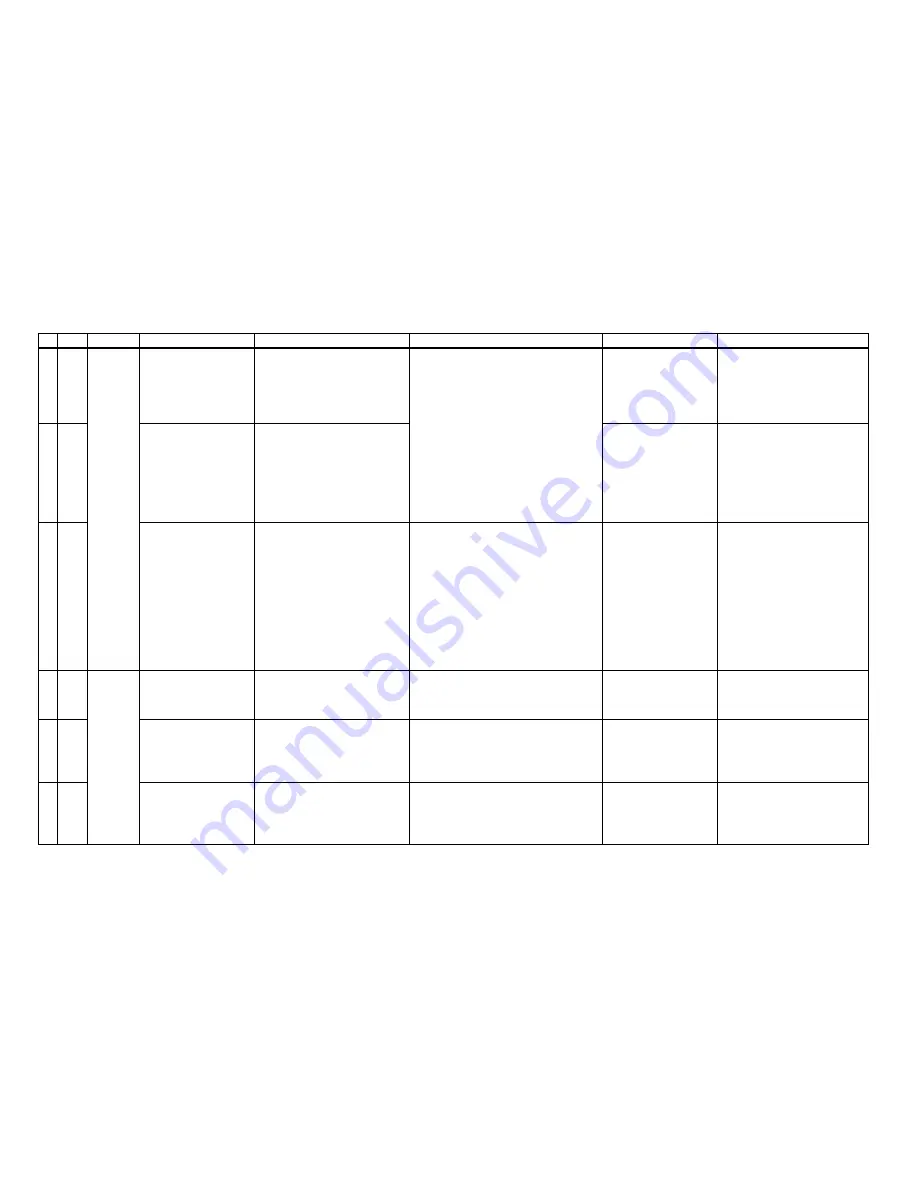

7-2. Product Technical Information

1) FAQ (Problems specific to the i320, and corrective actions)

No. Rank* Function

Phenomenon

Condition

Cause

Corrective action

Possible Call / Claim

1

A

No cartridge installation

error (orange LED blinks

6 times).

Cartridge cannot be

installed.

Carriage error.

The packing material used to fix

the carriage at unpacking and

installation may not have been

removed.

Remove the packing

material fixing the

carriage.

-LED blinks in orange 6 times

(no cartridge installation error)

-Cannot install the cartridge

-Cannot print

-LED blinks in orange and green

alternately twice (carriage error)

2

A

Carriage error, abnormal

noise, or paper feeding

without printing.

The packing material used to fix

the print head cap at unpacking

and installation may not have

been removed.

The user may have failed to remove the

packing material at unpacking and

installation.

Although a caution sheet is packaged

together with the printer, the user may not

notice it.

Note: Even if the packing material

remains, no parts are damaged.

Remove the packing

material fixing the print

head cap.

-LED blinks in orange and green

alternately twice (carriage error)

(As this occurs at printer

installation, the user cannot

recognize the error.)

-Abnormal noise

-Cannot print

-Paper feeding without printing

3

A

Installatio

n

Abnormal cartridge

EEPROM data error

(orange LED blinks 7

times).

The problem likely occurs when

the cartridge lever is slowly

(carefully) lowered at print head

installation.

When the cartridge lever is slowly lowered

at print head insta llation, there is a timing

mismatch in reading the print head

EEPROM value, preventing the EEPROM

value from being detected correctly.

<Print head recognition mechanism>

The print head installation is detected by

the contact of terminals in the following

procedure:

1. The existence of print head is detected.

2. The print head EEPROM value is

checked.

1. Power off the printer,

and re-power it on.

2. Remove the print

head, and reinstall it.

-LED blinks in orange 7 times

(cartridge EEPROM data error)

(As this occurs at printer

installation, the user cannot

recognize the error.)

-Cannot print

4

B

Paper not feeding when

lots of paper/media is

loaded. (PC101/PR101)

The problem may occur when

multiple pages of PC101L and

PR101 (A4/LTR) are loaded.

When the amount of paper curl is large

and multiple pages are loaded, the

loaded page limit level in the ASF creates

friction at paper feeding.

1. Decrease the number

of pages loaded in the

ASF.

2. Correct the paper curl.

-Paper out error

-Paper cannot be fed

-Cannot print

5

B

Multi-feeding.

When multiple pages of PR101

(A4/LTR) are loaded (in the high

temperature and high humidity

environment).

In the high temperature and high humidity

environment, the frictional force between

the PR101’s front and back sides

becomes high, and sheets stick to each

other, contributing to multi -feeding.

Set the paper one by one

in the ASF.

-Multiple pages of paper are fed

-Paper is delivered without

printing

6

B

Paper

feedability

Envelope not feeding.

When many envelopes are

loaded.

<Supplement>

The problem may occur with the

DL envelope.

The paper feed roller slips on the paper at

paper feeding.

Note: Depending on the paper lots.

1. Decrease the number

of envelopes loaded in

the ASF.

2. Straighten out the

paper (with a pen).

-Paper out error

-Paper cannot be fed

-Cannot print

Summary of Contents for i 320

Page 1: ...i320 SERVICE MANUAL Canon ...