COPYRIGHT © 2000 CANON INC.

COPYRIGHT © 2000 CANON INC. 2000 2000 2000 2000

2000 2000 2000 2000

CANON NW Multi-PDL P. kit-A1 REV.0 SEPT. 2000 PRINTED IN USA

CANON NW Multi-PDL P. kit-A1 REV.0 SEPT. 2000 PRINTED IN USA

CHAPTER 2 OPERATIONS

CHAPTER 2 OPERATIONS

2-6

2-6

2.2.2

2.2.2 Pr

Proc

oces

essi

sing b

ng by th

y the Pr

e Prin

inte

terr

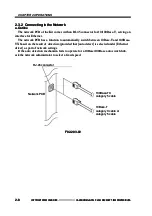

A print job coming from the parallel interface of the main controller PCB or the network

A print job coming from the parallel interface of the main controller PCB or the network

PCB is first checked by the main controller PCB to find out if it is in PCL or in PostScript

PCB is first checked by the main controller PCB to find out if it is in PCL or in PostScript

(PDL

(PDL identif

identification).

ication).

Then, the print job is sent to the RIP processing block for RIP processing by the main

Then, the print job is sent to the RIP processing block for RIP processing by the main

controller PCB and the RIP1 PCB operating simultaneously for conversion from PDL data

controller PCB and the RIP1 PCB operating simultaneously for conversion from PDL data

into image data.

into image data.

After smoothing and thickening processes on the main controller PCB, the print job is

After smoothing and thickening processes on the main controller PCB, the print job is

once stored on the hard disk drive.

once stored on the hard disk drive.

The system controller PCB reads the image data stored on the hard disk drive, and trans-

The system controller PCB reads the image data stored on the hard disk drive, and trans-

fers it to the DC controller PCB; the data is then used for laser exposure, development,

fers it to the DC controller PCB; the data is then used for laser exposure, development,

transfer, and fixing for the generation of a print.

transfer, and fixing for the generation of a print.

F02-202-02

F02-202-02

Print job

Print job

Print job

Print job

RIP

RIP

processing

processing

RIP1

RIP1

PCB

PCB

Parallel

Parallel

interface

interface

Smoothing/

Smoothing/

thickening

thickening

Network PCB

Network PCB

PDL

PDL

identification

identification

D

D

C

C

C

C

o

o

n

n

t

t

r

r

o

o

l

l

l

l

e

e

r

r

P

P

C

C

B

B

HDD

HDD