Assembly InstructIons for

stAndArd And eP rAcks

1

Material Verification:

Battery racks are shipped

unassembled with a complete set of related drawings and

documentation. Check received parts and quantities against

the rack’s bill of materials on provided drawings and/or

packing list. Do not assemble rack if parts are missing or

quantities are incomplete.

2

Required Tools:

Torque wrench (0 to 65 ft.-lb.) with 9/16”

and 3/4” Hex socket. Adjustable wrench or 9/16” and 3/4” box

wrenches, tape measure, square and leveling device.

Note:

Consult manufacturer’s instructions for tools required to

install floor mounting hardware.

3

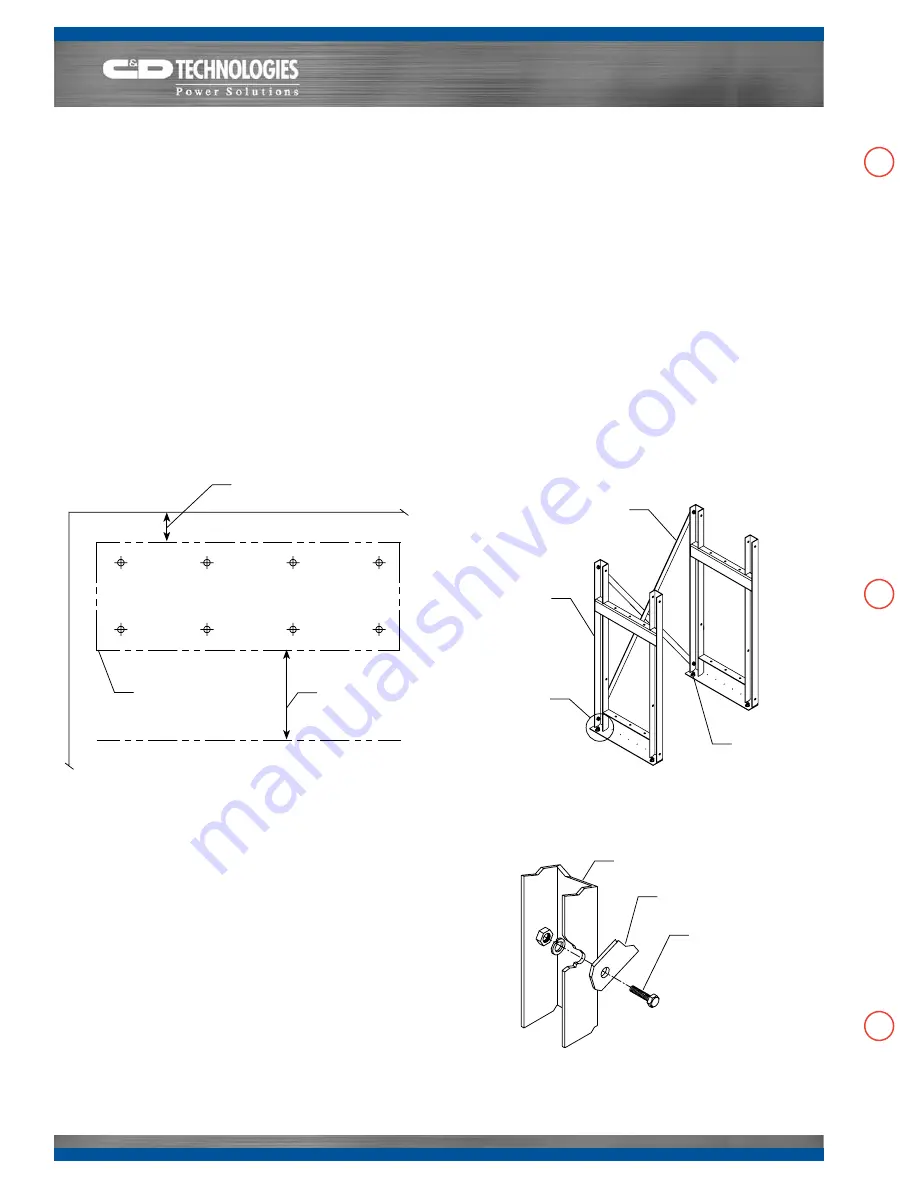

Location of Rack Assembly:

When determining rack

location and floor bolt pattern, use applicable drawings

provided with rack shipment. Locate the rack’s general position,

considering boundary and aisle clearances. Locate floor

mounting locations using provided drawings. See Figure 3.

Note:

Floor mounting hardware is to be determined in

accordance with applicable building codes, not by C&D.

4

Initial Assembly:

Place frames over installed floor

mounting hardware, finger tight. (Hardware not supplied by

C&D). All frames must face the same direction. Install back

cross braces, finger tight. See Figure 4. Do not install front

cross braces at this time (if required).

Note:

Cross bracing pattern along the length of the rack

may not necessarily be symmetric. Cross bracing pattern

and location(front, middle, or back) is detailed on assembly

drawing provided with the racks.

Figure 3. Rack Assembly Location

and Anchor Bolt Pattern

External Rack Dimensions.

See Assembly Drawing.

36” Typical Aisle

Clearance

2” Typical Clearance Around

Existing Boundary

Detail 1. Brace to Frame

connection (Reverse View)

1/2-13 Bolt, Lock

Washer and Nut

Cross Brace

Frame Upright

Figure 4. Initial Assembly

Frame and Cross

Brace Connection.

See Detail 1.

Floor Mounting

Hardware

Frame

Cross Brace(s)